Introduction

The EPRV Series Small Worm Gearboxes are essential components in various industrial applications. To ensure their longevity and optimal performance, it is crucial to implement proper maintenance and care. This article will provide comprehensive guidelines on extending the life of EPRV Series Small Worm Gearboxes, covering various aspects from lubrication to temperature control.

Table of Contents

- Understanding the EPRV Series Small Worm Gearboxes

- The Importance of Proper Lubrication

- Temperature Control for Enhanced Performance

- Regular Inspection and Maintenance

- Protective Measures against Overloading

- Significance of Precision in Gearbox Assembly

- Sealing and Contamination Prevention

- Efficient Power Transmission Techniques

- Noise Reduction Methods

- Gearbox Efficiency Optimization

- Choosing the Right Mounting Position

- Enhancing Gearbox Durability through Material Selection

- Understanding Gearbox Efficiency Ratios

- Load Distribution for Increased Longevity

- Ensuring Proper Input Shaft Alignment

- Importance of Backlash Control

- Appropriate Gearbox Ventilation

- Efficient Heat Dissipation

- Preventing Gear Tooth Wear

- Effective Vibration Damping Techniques

- Understanding the Impact of Shock Loads

- Correct Storage and Handling Methods

- Proper Installation Procedures

- Understanding Gearbox Failure Modes

- Importance of Regular Inspections and Testing

- Training and Education on Gearbox Maintenance

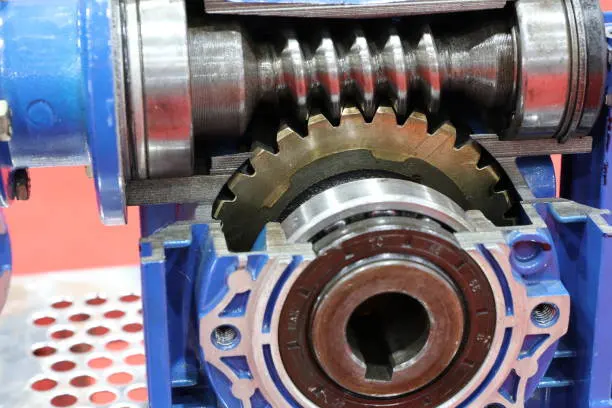

Understanding the EPRV Series Small Worm Gearboxes

The EPRV Series Small Worm Gearboxes are precision-engineered components designed to provide efficient power transmission in various industrial applications. These gearboxes consist of a worm screw and a worm wheel, which work in tandem to convert rotational motion into linear motion. The compact design and high torque capability make them suitable for diverse applications such as packaging machinery, conveyor systems, and automation equipment.

The Importance of Proper Lubrication

Proper lubrication is crucial for the smooth operation and longevity of EPRV Series Small Worm Gearboxes. The right lubricant ensures reduced friction, minimizes wear and tear, and prevents overheating. It is recommended to use high-quality lubricants specifically formulated for worm gears, considering factors such as viscosity, load, and operating temperature. Regular lubricant analysis and replenishment should be carried out to maintain optimal performance.

Temperature Control for Enhanced Performance

Controlling the temperature within the EPRV Series Small Worm Gearboxes is essential for preventing damage and ensuring long-term reliability. Excessive heat can lead to premature wear of gear teeth and lubricant degradation. Implementing proper cooling techniques such as external fans, heat sinks, or cooling jackets can help dissipate heat effectively. Monitoring the gearbox temperature and taking necessary measures to maintain it within the recommended range is crucial.

Regular Inspection and Maintenance

Regular inspection and maintenance are vital for identifying potential issues and preventing major failures. Inspecting the gearbox for signs of wear, misalignment, or abnormal noise can help detect problems early. Additionally, components such as seals, bearings, and shafts should be regularly checked and replaced if necessary. Following manufacturer’s guidelines for maintenance intervals and procedures is crucial for optimal gearbox performance.

Protective Measures against Overloading

Overloading can significantly impact the lifespan of EPRV Series Small Worm Gearboxes. It is essential to ensure that the gearbox is not subjected to loads beyond its rated capacity. Implementing overload protection mechanisms such as torque limiters or adjustable speed drives can prevent excessive stress on the gearbox, enhancing its longevity.

Significance of Precision in Gearbox Assembly

The precision of gearbox assembly plays a vital role in its overall performance and durability. Proper alignment of gears, shafts, and bearings is essential for reducing friction and preventing premature wear. Following manufacturer’s guidelines and using specialized tools for gearbox assembly can help achieve the required precision and ensure optimal performance.

Sealing and Contamination Prevention

Effective sealing is crucial for preventing contamination and maintaining the integrity of EPRV Series Small Worm Gearboxes. Seals should be regularly inspected for wear or damage and replaced if necessary. Additional measures such as breathers, filters, or protective covers can be implemented to minimize the ingress of dirt, dust, or moisture, which can compromise gearbox performance.

Efficient Power Transmission Techniques

Efficient power transmission is essential for maximizing the lifespan of EPRV Series Small Worm Gearboxes. Optimizing the gear meshing contact, reducing friction losses, and minimizing power loss due to heat are crucial factors. Advanced techniques such as tooth profiling, lubrication analysis, and material selection can contribute to improved power transmission efficiency.

Noise Reduction Methods

Noise generated during gearbox operation can indicate potential issues and impact user comfort. Implementing noise reduction methods such as precision machining, vibration damping, or sound insulation can help minimize noise levels. Identifying the source of noise and taking appropriate measures to address it can contribute to prolonged gearbox life.

Gearbox Efficiency Optimization

Optimizing the efficiency of EPRV Series Small Worm Gearboxes is critical for reducing energy consumption and increasing their lifespan. Factors such as gear design, lubrication, and load distribution can affect gearbox efficiency. By employing techniques such as gear tooth profile optimization, friction reduction, and proper lubricant selection, gearbox efficiency can be improved.

Choosing the Right Mounting Position

The mounting position of EPRV Series Small Worm Gearboxes can impact their performance and longevity. Proper alignment and orientation should be ensured to avoid excessive load or misalignment. Following manufacturer’s recommendations regarding mounting position and considering factors such as accessibility, maintenance, and ease of installation can contribute to enhanced gearbox life.

Enhancing Gearbox Durability through Material Selection

The selection of suitable materials for EPRV Series Small Worm Gearboxes is crucial for their durability and longevity. Factors such as mechanical strength, wear resistance, and corrosion resistance should be considered. Utilizing materials such as alloy steels, hardened surfaces, or coatings can enhance gearbox performance and extend its operational life.

Understanding Gearbox Efficiency Ratios

Gearbox efficiency ratios provide insight into the power loss during gear transmission. Understanding these ratios helps in identifying energy losses and optimizing gearbox design and operation. Analyzing factors such as gear tooth profile, lubrication, and load distribution can contribute to improved efficiency ratios and extended gearbox life.

Load Distribution for Increased Longevity

Proper load distribution among the gear teeth is crucial for preventing premature wear and increasing the lifespan of EPRV Series Small Worm Gearboxes. Ensuring uniform load distribution through techniques such as tooth profile optimization and gear design can minimize stress concentration and enhance gearbox durability.

Ensuring Proper Input Shaft Alignment

Proper alignment of the input shaft is essential for the smooth operation and longevity of EPRV Series Small Worm Gearboxes. Misalignment can lead to increased friction, vibration, and premature wear. Utilizing alignment tools and techniques such as laser alignment or dial indicators can help achieve the required alignment accuracy.

Importance of Backlash Control

Backlash refers to the clearance between gear teeth and is a critical factor in gearbox performance. Proper backlash control helps in reducing vibration, minimizing backlash-related noise, and increasing the lifespan of EPRV Series Small Worm Gearboxes. Techniques such as gear tooth profiling, gear mesh optimization, and precise assembly contribute to effective backlash control.

Appropriate Gearbox Ventilation

Proper ventilation is crucial for maintaining the temperature within EPRV Series Small Worm Gearboxes and preventing the accumulation of heat. Implementing ventilation techniques such as fans, vents, or cooling jackets can aid in dissipating heat and ensuring optimal gearbox performance. Periodic inspection of ventilation systems should be carried out to prevent blockages or obstructions.

Efficient Heat Dissipation

Efficient heat dissipation is essential for preventing overheating and extending the life of EPRV Series Small Worm Gearboxes. Heat sinks, heat exchangers, or cooling jackets can be employed to dissipate heat effectively. Monitoring the gearbox temperature and implementing appropriate cooling measures can contribute to prolonged gearbox life.

Preventing Gear Tooth Wear

Preventing gear tooth wear is crucial for maintaining the performance and longevity of EPRV Series Small Worm Gearboxes. Utilizing hardened gear materials, proper lubrication, and maintaining the recommended backlash can help minimize tooth wear. Regular inspection and monitoring of gear tooth condition are essential for timely identification and mitigation of wear-related issues.

Effective Vibration Damping Techniques

Vibration can negatively impact the performance and lifespan of EPRV Series Small Worm Gearboxes. Implementing vibration damping techniques such as resilient mounts, absorption materials, or tuned mass dampers can help minimize vibration levels. Identifying the source of vibration and applying suitable damping measures can contribute to prolonged gearbox life.

Understanding the Impact of Shock Loads

Shock loads can significantly affect the durability and performance of EPRV Series Small Worm Gearboxes. Implementing shock absorption techniques such as overload protection devices, elastic couplings, or shock-absorbing materials can help mitigate the impact of shock loads. Ensuring that the gearbox is designed to withstand and dissipate shock loads can contribute to prolonged service life.

Correct Storage and Handling Methods

Proper storage and handling of EPRV Series Small Worm Gearboxes are crucial for preventing damage and maintaining their optimal condition. Gearboxes should be stored in a clean, dry environment, protected from moisture or dust. Implementing proper handling techniques and using suitable lifting equipment can prevent accidental damage and ensure the longevity of the gearboxes.

Proper Installation Procedures

Proper installation procedures are essential for ensuring the optimal performance and longevity of EPRV Series Small Worm Gearboxes. Following manufacturer’s guidelines regarding alignment, torque specifications, and mounting procedures is crucial. Utilizing specialized tools and techniques for installation can help achieve the required accuracy and reliability.

Understanding Gearbox Failure Modes

Understanding the potential failure modes of EPRV Series Small Worm Gearboxes is essential for timely identification and mitigation of issues. Common failure modes include gear tooth wear, bearing failure, lubrication degradation, and misalignment. Regular inspection, monitoring, and analysis can help identify the early signs of failure and take appropriate corrective actions.

Importance of Regular Inspections and Testing

Regular inspections and testing are vital for ensuring the optimal performance and longevity of EPRV Series Small Worm Gearboxes. Periodic inspections, including visual inspection, lubricant analysis, and vibration analysis, can help detect potential issues before they escalate. Utilizing advanced testing techniques such as gear tooth analysis or thermal imaging can provide valuable insights into gearbox condition.

Training and Education on Gearbox Maintenance

Proper training and education on gearbox maintenance are essential for ensuring the effective care and longevity of EPRV Series Small Worm Gearboxes. Training programs can cover topics such as lubrication, inspection techniques, troubleshooting, and preventive maintenance. By empowering personnel with the necessary knowledge and skills, gearbox maintenance can be carried out efficiently.

Conclusion

The EPRV Series Small Worm Gearboxes are vital components in various industrial applications, and their lifespan can be significantly extended through proper care and maintenance. By implementing the guidelines mentioned in this article, including proper lubrication, temperature control, regular inspection, and protective measures, the performance and durability of EPRV Series Small Worm Gearboxes can be enhanced. At [Your Company Name], we are committed to providing high-quality gearboxes and supporting products to meet your industrial needs.

Electric motors for Sale

The relationship between gearboxes and electric motors is symbiotic, with each component relying on the other for optimal performance. Gearboxes, such as the EPRV Series Small Worm Gearboxes, play a crucial role in reducing the motor’s speed while increasing torque, enabling precise control and efficient power transmission. On the other hand, electric motors provide the necessary power to drive the gearbox, ensuring smooth operation and reliable performance.

At [Your Company Name], we offer a comprehensive range of electric motors that are perfectly matched with our high-quality gearboxes. Our electric motors are designed to meet the demanding requirements of various industrial applications. With advanced features such as high efficiency, low noise, and reliable performance, our electric motors provide the perfect complement to our gearbox offerings.

About Us

RP Techniek BV, as the Netherlands sales agent of the Ever-power Group, is a renowned name in the transmission equipment industry. With over 25 years of experience, we specialize in the design, manufacturing, and sales of speed reducers. Serving customers across Europe, America, Africa, Asia, and other regions, we have established a reputation for providing high-quality products and exceptional service.

At [Your Company Name], our manufacturing capabilities are backed by advanced production equipment and testing facilities. We have a team of industry professionals and technicians dedicated to innovative research and development, ensuring that our gearboxes meet the highest standards of quality and performance. Our commitment to standardized production management enables us to maintain strict control over every aspect of gearbox production, ensuring consistent excellence.

Our gearboxes find applications in a wide range of industries, including equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar energy industry, and more. We take pride in the trust and satisfaction of our customers, who rely on our gearboxes for their critical operations.

At [Your Company Name], we encourage you to explore our range of products and experience the