Introduction

EPRV series small worm gearboxes are an important part of various machinery and equipment. They play a crucial role in power transmission and motion control. Therefore, it is essential to calculate their power requirements accurately. In this article, we will discuss the method of calculating the power requirements for EPRV series small worm gearboxes.

What are EPRV Series Small Worm Gearboxes?

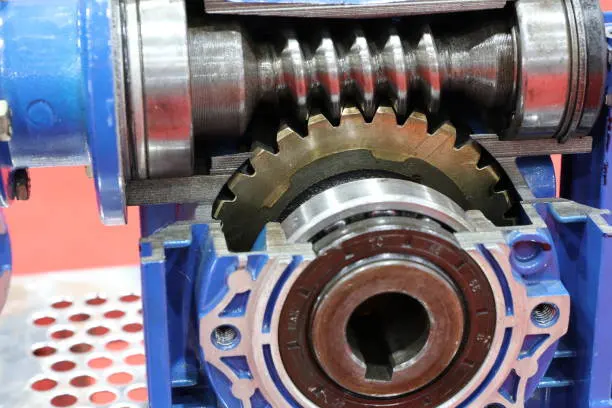

EPRV series small worm gearboxes are compact, highly efficient gearboxes that are widely used in various industries. They are known for their high torque capacity, low noise, and long service life. These gearboxes are constructed with a worm and worm gear, which provide a high reduction ratio in a compact design. The input shaft is perpendicular to the output shaft, making them a popular choice for applications with limited space.

How to Calculate the Power Requirements for EPRV Series Small Worm Gearboxes

Step 1: Determine the Input Power

The first step in calculating the power requirements for EPRV series small worm gearboxes is to determine the input power required for your application. Input power is the amount of power required to drive the gearbox. It can be calculated using the following formula:

Input Power (W) = Torque (Nm) x Speed (RPM) / 9550

Where:

- Torque is the amount of force required to rotate the gearbox output shaft.

- Speed is the rotational speed of the gearbox output shaft in revolutions per minute (RPM).

- 9550 is a constant used to convert the torque and speed units to watts.

It is essential to calculate the input power accurately because it determines the size and capacity of the electric motor required to drive the gearbox.

Step 2: Determine the Gearbox Efficiency

The next step is to determine the gearbox efficiency. Gearbox efficiency is the percentage of input power that is transmitted to the output shaft. It can be calculated using the following formula:

Efficiency (%) = (Output Power / Input Power) x 100

Where:

- Output Power is the amount of power delivered to the gearbox output shaft.

- Input Power is the amount of power required to drive the gearbox.

The gearbox efficiency is affected by several factors, including the quality of the gearbox components, the lubrication of the gearbox, and the operating temperature.

Step 3: Determine the Output Torque

The final step is to determine the output torque of the gearbox. Output torque is the amount of force that the gearbox output shaft can produce. It can be calculated using the following formula:

Output Torque (Nm) = Input Power (W) x 9550 / Speed (RPM)

Where:

- Input Power is the amount of power required to drive the gearbox.

- Speed is the rotational speed of the gearbox output shaft in revolutions per minute (RPM).

- 9550 is a constant used to convert the input power and speed units to newton-meters (Nm).

The output torque is essential to ensure that the gearbox can handle the load of your application. It is necessary to choose a gearbox with a higher output torque than the torque required for your application to ensure proper operation and prevent premature gearbox failure.

Electric motors for Sale

Electric motors and gearboxes are interdependent components in many applications. A gearbox reduces the speed and increases the torque of an electric motor, making it suitable for various applications. At our company, we offer a wide range of electric motors for sale that are compatible with our EPRV series small worm gearboxes. Our electric motors are efficient, durable, and meet the highest quality standards. We also offer custom electric motors to meet specific application requirements. Contact us to learn more about our electric motors and gearboxes and how they can benefit your application.

About Us

RP Techniek BV is the authorized sales agent of the Ever-power Group in the Netherlands. As a comprehensive transmission equipment manufacturer, we specialize in research and development, manufacturing, and sales of speed reducers. We have over 25 years of experience in the design, production, and sales of gearboxes, serving customers in Europe, America, Africa, Asia, and other regions. Our company has introduced advanced production and testing equipment from home and abroad, employed industry professionals and technicians to carry out innovative research and development and manufacturing. We use standardized production management methods to strictly control every aspect of the production of reducers, providing customers with high-quality, high-energy-efficiency, high-stability production of crystals. Our gearboxes are widely used in various industries, such as the equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, and solar energy industry. We welcome and trust our customers and encourage you to explore our products and contact us for purchasing.

Q&A

Q1: What is the difference between EPRV series small worm gearboxes and other types of gearboxes?

A1: EPRV series small worm gearboxes have a high reduction ratio, a compact design, and low noise compared to other types of gearboxes.

Q2: How can I determine the input power required for my application?

A2: You can determine the input power required for your application using the formula Input Power (W) = Torque (Nm) x Speed (RPM) / 9550.

Q3: Why is gearbox efficiency important?

A3: Gearbox efficiency determines the amount of input power that is transmitted to the output shaft. A high gearbox efficiency means less power loss and less heat generated, resulting in increased gearbox life and reduced operating costs.

Q4: How can I ensure that the gearbox can handle the load of my application?

A4: You can ensure that the gearbox can handle the load of your application by choosing a gearbox with a higher output torque than the torque required for your application.

Q5: Are electric motors and gearboxes compatible with each other?

A5: Yes, electric motors and gearboxes are interdependent components in many applications. A gearbox reduces the speed and increases the torque of an electric motor, making it suitable for various applications.

Edited by: Zqq.