PersonnelOur revenue persons are nicely skilled to accommodate your requests and talk English for your convenience.

Overview

Quick Details

- Relevant Industries:

-

Production Plant

- Regional Support Spot:

-

None

- Surface area Therapy:

-

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating

- Yr:

-

2014-2016, 2014-2015, 2010-2016ear:

- Tolerance:

-

Based mostly on drawingLength Dimension

- Normal:

-

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Specification:

-

In accordance to the the drawing

- Warmth remedy:

-

Quenching & Tempering, Carburizing & Quenching

- model:

-

CT660, X-BOW

Supply Capability

- Offer Capability:

- 5000 Piece/Items for every Thirty day period

Packaging & Supply

- Packaging Specifics

- Neutral paper packaging, wood containers for outer box or in accordance to customer's desire.

- Port

- Shanghai / Ningbo

-

Lead Time

: -

Quantity(Parts) 1 – one thousand >1000 Est. Time(times) 15 To be negotiated

On-line Customization

We Ever-Electrical power Group with four branches over 1200 workers is one particular of the biggest transmission components and machining objects companies in China

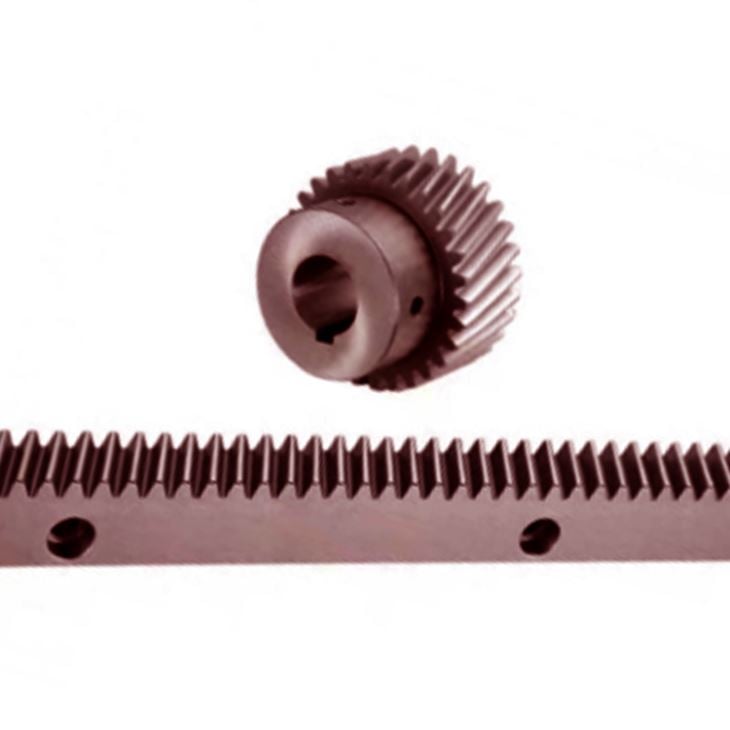

Product Description

higher good quality cnc machining stainless metal propeller atv rear axle shaft

(one)All sorts of gears, shaft, gear shaft, precision gear and CNC gear.

(2)Specialized in producing all varieties of auto transmission portion based mostly on Drawings.

(three)Materials: ductile solid iron, carbon steel, alloy steel , stainless metal, bronze/brass.

(4)Modules: M1 to M8 .

(five)Satisfies ISO, DIN and ASTM standards .

(six)Specification : According to the the drawing.

|

Materials |

Carbon Steel |

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214Letc |

|

Alloy Steel |

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc |

|

|

Brass/Bronze |

HPb59-one, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40etc |

|

|

Tolerance Manage |

Outer Diameter |

Based on drawing |

|

Duration Dimension |

Based on drawing |

|

|

Machining Method |

Gear Hobbing, Gear Milling, Equipment Shaping, Equipment Broaching, Gear Shaving, Equipment Grinding and Equipment Lapping |

|

|

Teeth Precision |

DIN Class 4, ISO/GB Course 4, AGMA Course thirteen, JIS Class |

|

|

Modules |

one., one.25, one.5, 1.75, two., 2.25, 2.five….eight. and so on |

|

|

Heat Treatment |

Quenching & Tempering, Carburizing & Quenching, Higher-frequency Hardening, Carbonitriding |

|

|

Area Remedy |

Blacking, Sharpening, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|

|

Regular |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

|

Packaging & Transport