Introduction

Drop forged rivetless chains are widely used in various industries due to their durability and strength. This article explores the different industries that utilize these chains and highlights their importance in each sector.

1. Automotive Industry

The automotive industry heavily relies on drop forged rivetless chains for various applications. These chains are commonly used in conveyor systems for transporting heavy components and assemblies along the production line. Their high load capacity and resistance to wear make them ideal for this industry.

2. Steel Mills

In steel mills, drop forged rivetless chains are essential for the movement of heavy steel coils and billets. These chains can withstand extreme temperatures and harsh environments, ensuring efficient and reliable material handling operations.

3. Mining Industry

Drop forged rivetless chains are extensively used in the mining industry for conveying bulk materials, such as coal, ore, and minerals. The chains' robust construction and ability to handle heavy loads make them suitable for demanding mining applications.

4. Food Processing

Food processing plants rely on drop forged rivetless chains for their conveyor systems. These chains are used to transport food products through various stages of processing, ensuring smooth and hygienic operations. Their corrosion resistance and easy maintenance are crucial in maintaining food safety standards.

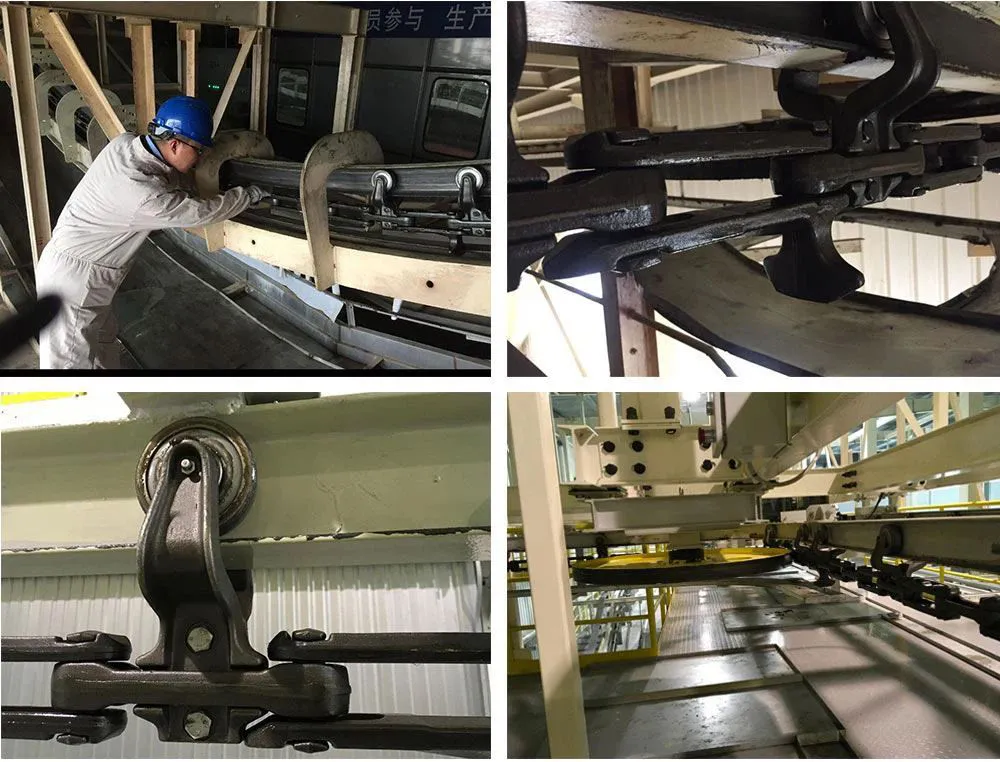

5. Material Handling

Drop forged rivetless chains play a vital role in material handling equipment, such as overhead conveyors and hoists. These chains provide reliable and efficient movement of goods in warehouses, distribution centers, and other logistics facilities.

6. Packaging Industry

The packaging industry utilizes drop forged rivetless chains in packaging machinery to ensure precise and efficient movement of products during the packaging process. These chains contribute to high-speed operations and reduce downtime.

7. Construction Industry

In the construction industry, drop forged rivetless chains are commonly used in heavy-duty equipment, such as excavators and cranes. These chains provide the necessary strength and durability to withstand the demanding conditions of construction sites.

8. Agriculture

Agricultural machinery, including combines, harvesters, and grain conveyors, relies on drop forged rivetless chains for their robustness and reliability. These chains effectively handle the heavy loads and harsh environments associated with agricultural operations.

9. Paper Industry

Drop forged rivetless chains are extensively used in the paper industry for moving paper rolls and other paper-related products. These chains ensure smooth and efficient paper production processes, even in high-speed environments.

10. Renewable Energy

In the renewable energy sector, drop forged rivetless chains are used in wind turbines for the rotation mechanisms. These chains provide the necessary strength and durability to withstand the extreme forces exerted by wind turbine blades.

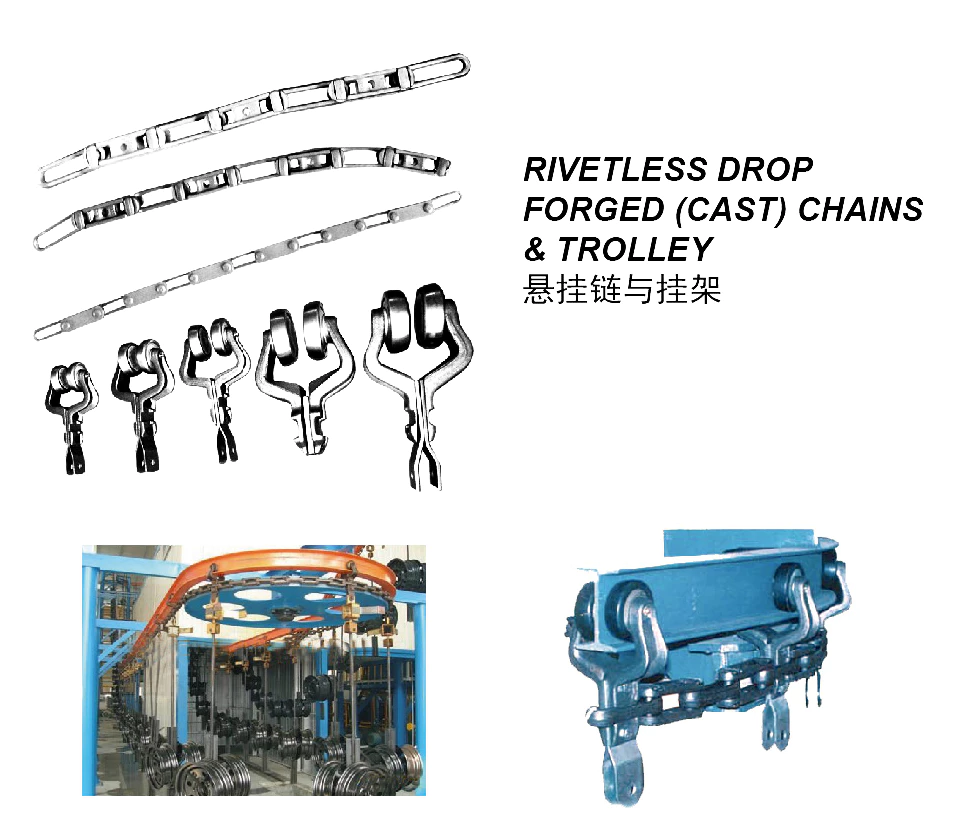

Sprockets for Drop Forged Rivetless Chains

Drop forged rivetless chains and sprockets are complementary components that work together to ensure efficient and reliable power transmission. The sprockets, attached to the shaft, engage with the chain, allowing it to move smoothly along the conveyor or machinery.

The relationship between drop forged rivetless chains and sprockets is crucial for maintaining proper tension, reducing wear, and preventing chain slippage. These components work in harmony, ensuring precise and reliable movement in various industrial applications.

At Ever-power Group, we offer a wide range of drop forged rivetless chain sprockets to complement our chain offerings. Our sprockets are designed and manufactured with high-quality materials to ensure optimal performance and longevity.

About Us

RP Techniek BV, the Netherlands sales agent of Ever-power Group, is a leading supplier of drop forged rivetless chains. Our product range includes various types of forged chains, conveyor chains, and detachable chains such as X348, X458, X678, and X698. We specialize in customizing our products to your specific requirements based on your drawings or samples.

We provide high-quality products made from materials like 40Cr, 20CrMnTi, and 42CrMo to meet your needs. Our product line also includes extended pin chains and pusher chains to cater to different customer demands. We also manufacture special chains, pins, and plates based on your requirements.

With over 90% of our products exported to markets like the United States, Canada, Japan, South Korea, Brazil, and Australia, we are committed to providing competitive prices and excellent service. We encourage you to explore our range of products and contact us for any inquiries or purchases.

Q&A

Q1: What are the advantages of drop forged rivetless chains compared to other types of chains?

A1: Drop forged rivetless chains offer superior strength, durability, and resistance to wear, making them ideal for heavy-duty applications in various industries.

Q2: Can drop forged rivetless chains be customized to specific requirements?

A2: Yes, at Ever-power Group, we specialize in customizing drop forged rivetless chains based on your drawings or samples to meet your exact needs.

Q3: Are drop forged rivetless chains suitable for high-temperature environments?

A3: Yes, these chains are designed to withstand extreme temperatures, making them suitable for applications in industries such as steel mills and foundries.

Q4: How do drop forged rivetless chains contribute to increased productivity?

A4: These chains provide smooth and reliable movement, reducing downtime and ensuring efficient material handling, resulting in increased productivity.

Q5: What maintenance is required for drop forged rivetless chains?

A5: Regular lubrication and periodic inspection for wear are recommended to prolong the lifespan and ensure optimal performance of drop forged rivetless chains.

Edited by: Zqq.

“