Introduction

When it comes to industrial machinery, chains are an essential component. Chains can be used for a wide variety of tasks, from carrying heavy loads to driving conveyor belts. However, not all chains are created equal. In this article, we will explore the key differences between riveted chains and rivetless chains, and the benefits of each.

Riveted Chains

Riveted chains are assembled using rivets that are driven through the chain's links. The rivets hold the links together, creating a strong and sturdy chain. One of the main advantages of riveted chains is their ability to withstand heavy loads and high speeds. Riveted chains are also highly resistant to wear and tear, making them ideal for use in harsh environments.

Advantages of Riveted Chains

- Can withstand heavy loads and high speeds

- Highly resistant to wear and tear

- Can be used in harsh environments

Disadvantages of Riveted Chains

- Difficult to disassemble and repair

- Rivets can loosen over time

- Not suitable for use in applications that require frequent disassembly

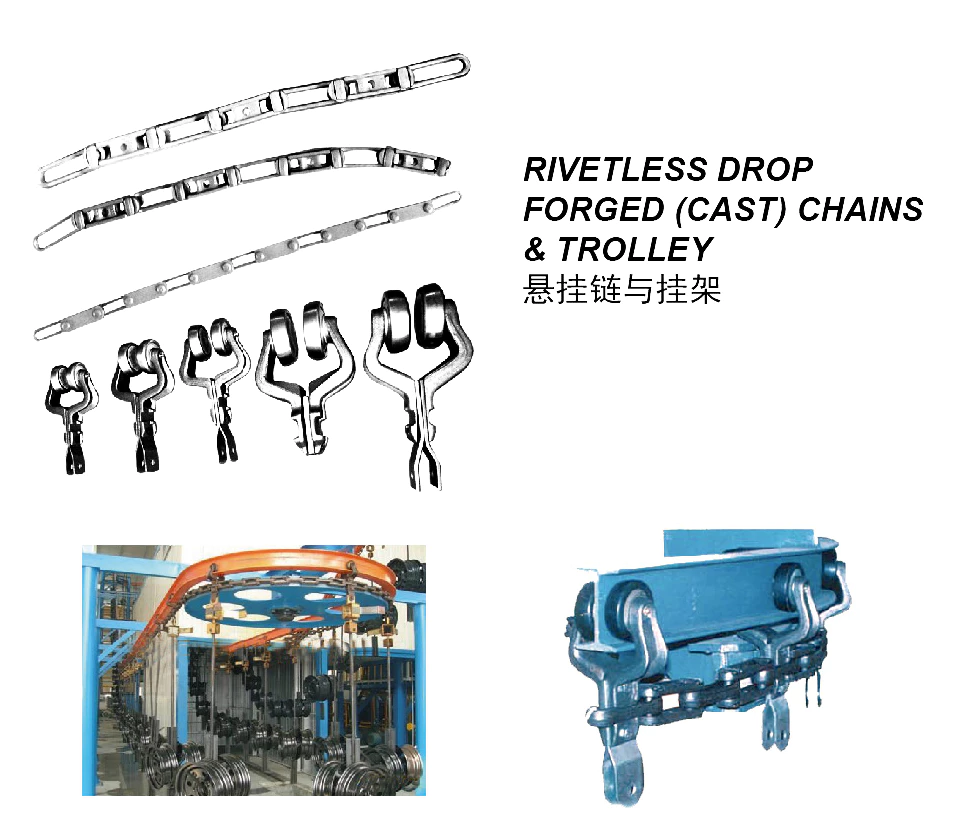

Rivetless Chains

Rivetless chains, also known as cotter-pin chains or snap-ring chains, are held together by removable pins that are secured with cotter pins or snap rings. The pins can be easily removed, allowing the chain to be disassembled and repaired as needed. Rivetless chains are often used in applications that require frequent disassembly, such as conveyor belts.

Advantages of Rivetless Chains

- Easy to disassemble and repair

- Suitable for use in applications that require frequent disassembly

- Can be used in a variety of industries

Disadvantages of Rivetless Chains

- Not as strong as riveted chains

- May require more frequent maintenance

- Not suitable for use in harsh environments

Applications of Riveted and Rivetless Chains

Both riveted and rivetless chains have their own unique advantages and disadvantages, making them suitable for different applications. Riveted chains are ideal for use in heavy-duty applications, such as mining and construction, while rivetless chains are often used in manufacturing and packaging industries.

Sprockets for Drop Forged Rivetless Chains

Sprockets and chains work together to provide a reliable and efficient means of transmitting power and motion. Drop forged rivetless chains and sprockets are no exception. The sprockets are specifically designed to work with drop forged rivetless chains, providing a high degree of accuracy and reliability. At our company, we offer a wide range of drop forged rivetless chain sprockets for all your industrial needs.

About Us

RP Techniek BV is the Netherlands sales agent of the Ever-power Group. We are a leading supplier of drop forged rivetless chains, conveyor chains, and detachable chains such as X348, X458, X678, and X698. Our products can be custom made to fit your drawings or samples. We offer high-quality products made from materials such as 40Cr, 20CrMnTi, and 42CrMo to meet your requirements. Our product line includes extended pin chains and pusher chains to meet different customer needs. We also manufacture special chains, pins, and plates upon request. Over 90% of our products are exported to markets such as the United States, Canada, Japan, Korea, Brazil, and Australia. We are committed to providing competitive prices and excellent service. We encourage you to explore our products and contact us for purchasing needs.

Q&A

Q1: What is the difference between a riveted chain and a rivetless chain?

A1: The main difference between a riveted chain and a rivetless chain is the way they are assembled. Riveted chains are assembled using rivets, while rivetless chains are held together by removable pins.

Q2: What are the advantages of using a riveted chain?

A2: Riveted chains are highly resistant to wear and tear and can withstand heavy loads and high speeds.

Q3: What are the advantages of using a rivetless chain?

A3: Rivetless chains are easy to disassemble and repair, making them ideal for applications that require frequent maintenance.

Q4: What are the disadvantages of using a riveted chain?

A4: Riveted chains are difficult to disassemble and repair and may not be suitable for applications that require frequent disassembly.

Q5: What are the disadvantages of using a rivetless chain?

A5: Rivetless chains may require more frequent maintenance and are not as strong as riveted chains.

Edited by: Zqq.