Introduction

Washdown worm reducers are an essential part of many different types of machinery that require sanitary processing. In Eindhoven, where many plants and factories require high-quality equipment, washdown worm reducers are a popular choice. These reducers are designed with materials and features that allow them to withstand the harsh conditions of washdown environments, ensuring longevity and efficiency.

What is a Washdown Worm Reducer?

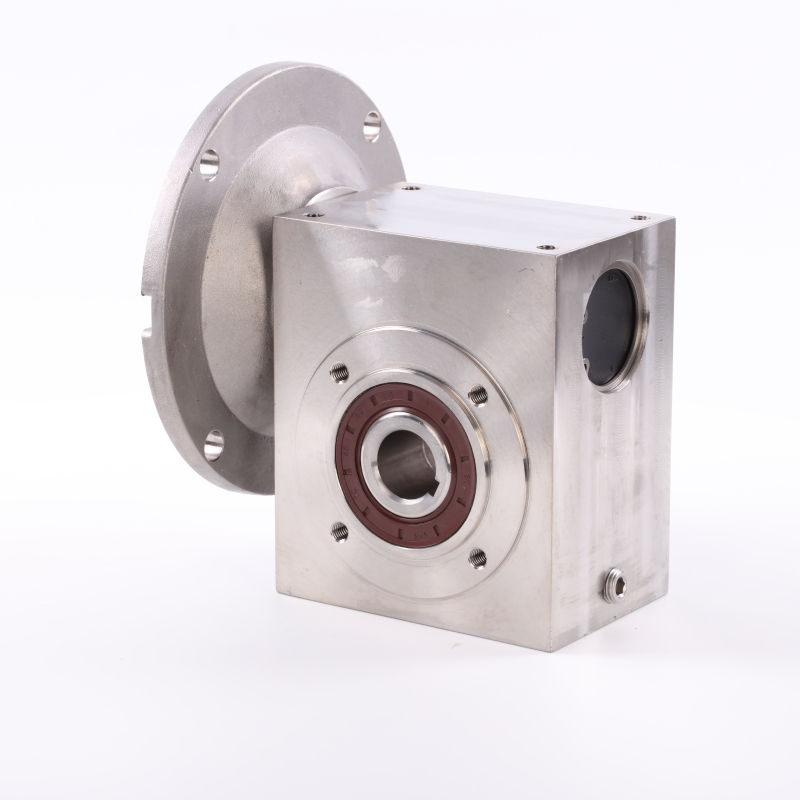

A washdown worm reducer is a type of gearbox that is designed to withstand frequent and harsh washdowns in sanitary environments. These gearboxes have a unique design that allows them to be cleaned effectively without damage to the gearbox. The housing is made of stainless steel to prevent corrosion, and the interior components are designed to resist water damage.

Benefits of Washdown Worm Reducers

There are many benefits to using washdown worm reducers in Eindhoven:

- They are designed to withstand frequent and harsh washdowns, reducing maintenance costs and downtime.

- Their stainless steel construction prevents corrosion and damage from water exposure.

- They are available in many sizes and ratios to fit a variety of machinery types.

- They are cost-effective and offer long-lasting durability, reducing the need for frequent replacements.

Applications of Washdown Worm Reducers

Washdown worm reducers are commonly used in many different types of machinery, including:

- Food processing equipment

- Beverage bottling equipment

- Pharmaceutical manufacturing equipment

- Clean room applications

- Chemical processing equipment

Features of Washdown Worm Reducers

Washdown worm reducers have several features that make them ideal for use in sanitary environments:

- Stainless steel construction

- Smooth surface finish to prevent bacteria growth

- Sealed design to prevent water damage

- Corrosion-resistant

- Available in many sizes and ratios

Installation of Stainless Steel Worm Gearboxes and Motors

Installation of stainless steel worm gearboxes and motors is relatively straightforward and can be completed by a qualified technician. First, ensure that the gearbox and motor are compatible and that the motor is correctly mounted. Next, connect the motor to the gearbox using a coupling. Finally, mount the gearbox in the desired location and connect it to the equipment. Always follow the manufacturer's instructions for installation and maintenance.

Issues with Washdown Worm Reducers and Solutions

| Issue | Solution |

|---|---|

| Corrosion of gearbox housing | Use a stainless steel housing to prevent corrosion |

| Water damage to gearbox components | Use a sealed design and corrosion-resistant materials |

| Malfunctioning gearbox | Perform regular maintenance and replace worn or damaged components as needed |

| Compatibility issues with equipment | Ensure that the gearbox is compatible with the equipment and that it is correctly installed |

| Overheating of gearbox | Ensure that the gearbox is properly lubricated and that it is not overloaded |

Stainless Steel Geared Motors for Sale

Stainless steel geared motors are an essential component of machinery that requires sanitary processing. These motors work in conjunction with washdown worm reducers to provide efficient and reliable performance. At RP Techniek BV, we offer a range of stainless steel geared motors for sale, including the latest models from top manufacturers. Our motors are designed to withstand harsh washdown conditions, ensuring longevity and efficiency.

Stainless steel geared motors and washdown worm reducers work together to provide optimal performance in sanitary environments. The motor provides the power needed to drive the equipment, while the reducer ensures that the equipment operates at the correct speed and torque. At RP Techniek BV, we understand the importance of this relationship, and we offer a range of high-quality stainless steel geared motors to meet the needs of all our clients.

About Us

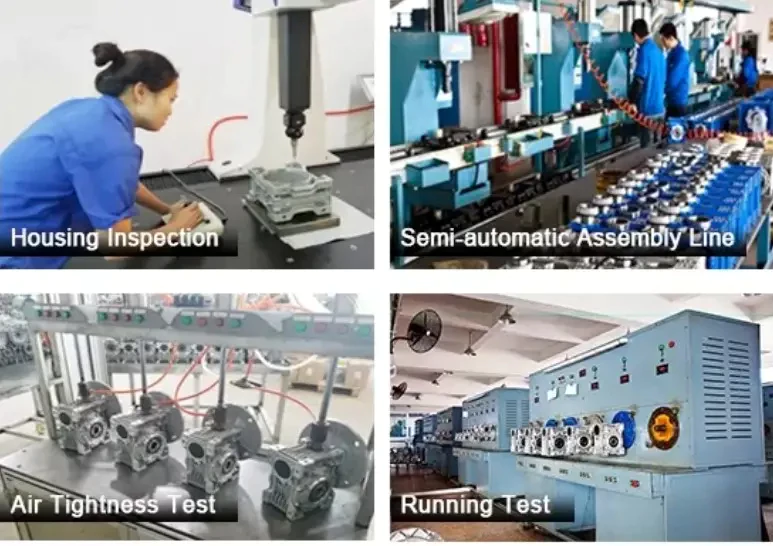

RP Techniek BV is the Netherlands sales agent of the Ever-power Group. We specialize in the production and sale of high-quality stainless steel worm gearboxes, geared motors, and other essential equipment for sanitary processing. Our products are designed to meet the needs of a wide range of industries, including food and beverage, pharmaceuticals, and chemicals.

At RP Techniek BV, we pride ourselves on providing our clients with the best possible service, the highest quality products, and competitive pricing. We have a reputation for excellence in the industry and are committed to ensuring that our clients have access to the best equipment available.

If you are interested in exploring our range of products or have any questions about our services, please do not hesitate to contact us. We are always happy to help and look forward to hearing from you.

Q&A

1. What is the difference between a washdown worm reducer and a standard worm reducer?

A washdown worm reducer is designed specifically for use in sanitary environments and is constructed of materials that can withstand frequent and harsh washdowns. A standard worm reducer does not have these features and is not suitable for use in these types of environments.

2. Are washdown worm reducers more expensive than standard worm reducers?

Washdown worm reducers can be more expensive than standard worm reducers due to their specialized features and construction. However, they offer long-lasting durability and reduced maintenance costs, making them a cost-effective choice in the long run.

3. Can washdown worm reducers be used in clean room applications?

Yes, washdown worm reducers are suitable for use in clean room applications. Their stainless steel construction and sealed design make them ideal for use in these types of environments.

4. How often should washdown worm reducers be maintained?

Washdown worm reducers should be maintained according to the manufacturer's instructions. Regular maintenance can help prevent issues and extend the life of the gearbox.

5. Can RP Techniek BV provide custom washdown worm reducers?

Yes, RP Techniek BV can provide custom washdown worm reducers to meet the specific needs of our clients. Contact us for more information.

Edited by: Zqq.