Introduction

Washdown Worm Reducers are an essential component in CIP (Clean-in-Place) systems used in various industries. These systems are widely employed in Brussels and other cities to ensure efficient cleaning and sanitization of equipment and pipelines. In this blog post, we will explore the features and benefits of Washdown Worm Reducers, their installation process, and common issues that may arise during their usage. Let's dive in!

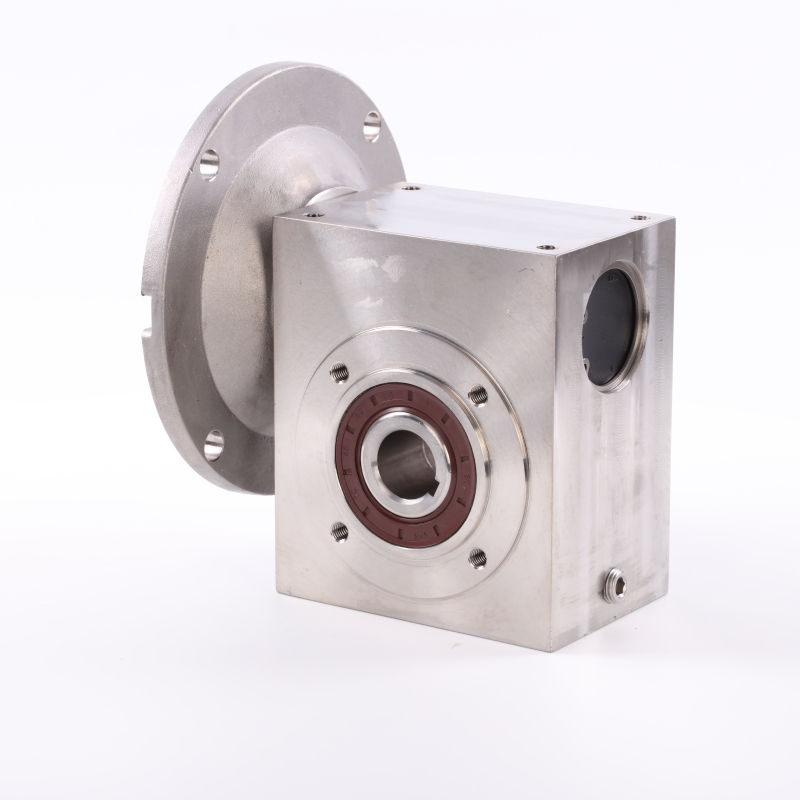

What is a Washdown Worm Reducer?

A Washdown Worm Reducer is a specialized gearbox designed to provide reliable power transmission in demanding CIP environments. It consists of a worm gear and a worm wheel, both made of high-quality stainless steel, ensuring resistance to corrosion, chemicals, and high-pressure washdowns. The reducer's compact design and efficient operation make it ideal for use in various industries, including food and beverage, pharmaceuticals, and chemical processing.

Features of Washdown Worm Reducers

- Stainless steel construction for enhanced durability

- Sealed housing to prevent ingress of contaminants

- Smooth operation with low noise and vibration levels

- High efficiency for energy savings

- Wide range of gear ratios available for different applications

- Easy installation and maintenance

Benefits of Washdown Worm Reducers

Washdown Worm Reducers offer several advantages in CIP systems:

- Reliable power transmission for smooth operation of equipment

- Enhanced cleanliness and hygiene due to stainless steel construction

- Long service life with minimal maintenance requirements

- Protection against corrosion, chemicals, and high-pressure washdowns

- Cost-effective solution for improved productivity and efficiency

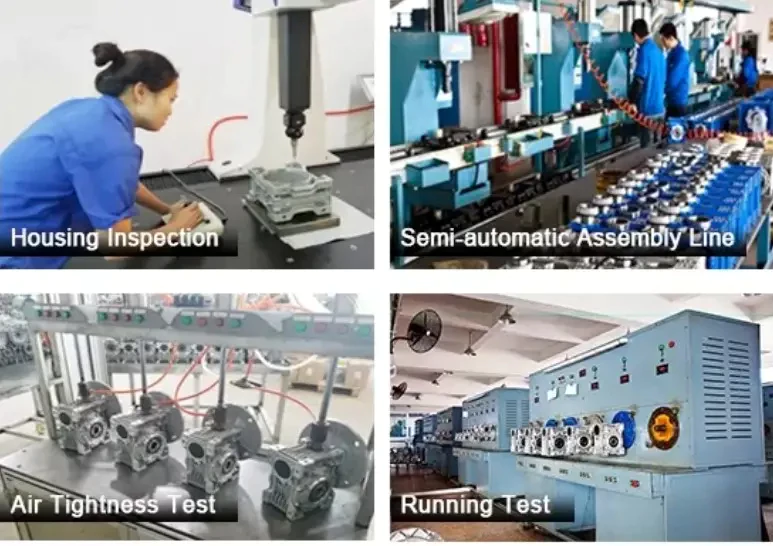

Installation Process of Stainless Steel Worm Gearboxes and Motors

The installation of stainless steel worm gearboxes and motors is a crucial step to ensure optimal performance and longevity of the system. Here are the general steps involved:

- Ensure proper alignment of the gearbox and motor.

- Use a coupling or adapter to connect the motor shaft to the gearbox input shaft.

- Securely fasten the gearbox and motor to the mounting surface using appropriate bolts or screws.

- Check the alignment again and make adjustments if necessary.

- Connect the electrical wiring as per the motor manufacturer's instructions.

- Perform a thorough inspection of the installation to ensure all connections are secure.

- Test the system to verify smooth operation and troubleshoot any issues if encountered.

Proper installation of stainless steel worm gearboxes and motors is crucial for optimal performance and reliability. It is recommended to consult the manufacturer's guidelines and seek professional assistance if needed.

Common Issues and Troubleshooting

Despite their robust design and reliable performance, stainless steel worm gearboxes can encounter certain issues during their usage. Here are some common problems that may arise:

| Problem | Solution |

|---|---|

| Excessive noise and vibration | Check for misalignment or worn-out gears. Lubricate the gearbox if necessary. |

| Overheating | Ensure proper ventilation and cooling. Check for any obstructions in the surrounding area. |

| Oil leakage | Inspect seals and gaskets for damage. Replace if necessary. |

| Loss of efficiency | Clean the gearbox and gears from debris. Lubricate the gears with the recommended oil. |

| Electrical issues | Check the motor connections and electrical supply. Consult an electrician if needed. |

Stainless Steel Geared Motors for Sale

The relationship between gearboxes and motors is symbiotic in any power transmission system. In the case of stainless steel worm gearboxes, they work hand in hand with stainless steel motors to ensure reliable and efficient operation. At our company, we offer a wide range of high-quality stainless steel motors that complement our gearboxes perfectly.

Stainless steel motors provide the necessary power and torque to drive the worm gearboxes, ensuring smooth and precise motion control. The compatibility between these components is crucial for maximizing system performance and longevity.

About Us

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. We specialize in providing top-notch stainless steel worm gear reducers and have established a strong reputation among our customers in Europe and America. Our manufacturing capabilities, combined with our commitment to delivering the highest quality products at competitive prices, have made us a trusted partner in the industry.

With our extensive product range and exceptional service, we encourage customers to explore our offerings and contact us for their purchase needs. We are here to assist you in finding the perfect solution for your power transmission requirements.

Q&A

Q: What is the maximum torque capacity of a Washdown Worm Reducer?

A: The maximum torque capacity of a Washdown Worm Reducer depends on its size and gear ratio. It is recommended to consult the product specifications or contact the manufacturer for accurate information.

Q: Can I use a Washdown Worm Reducer in a high-temperature environment?

A: Washdown Worm Reducers can withstand moderately high temperatures, but it is crucial to ensure they are within their specified operating temperature range. For extreme temperature conditions, specialized high-temperature gearboxes are available.

Q: How often should I lubricate the gears of a Washdown Worm Reducer?

A: The frequency of lubrication depends on the operating conditions and manufacturer's recommendations. In general, it is recommended to inspect and lubricate the gears periodically to ensure smooth operation and prolong the gearbox's service life.

Q: Can I use a Washdown Worm Reducer in a corrosive environment?

A: Yes, Washdown Worm Reducers are specifically designed to resist corrosion and chemicals. Their stainless steel construction provides excellent protection against corrosive environments, making them suitable for various industries.

Q: Do Washdown Worm Reducers require any special maintenance?

A: Washdown Worm Reducers have minimal maintenance requirements. Regular inspections, lubrication, and cleaning are generally sufficient to ensure their optimal performance. It is essential to follow the manufacturer's maintenance guidelines for specific recommendations.

Edited by: Zqq.