Introduction

In this article, we will explore the topic of Washdown Safe Stainless Steel Worm Gear Reducers in Hamburg. We will delve into the intricacies and importance of these gear reducers in various applications. From their composition to their installation process, we will cover all aspects to provide a comprehensive understanding of this technology.

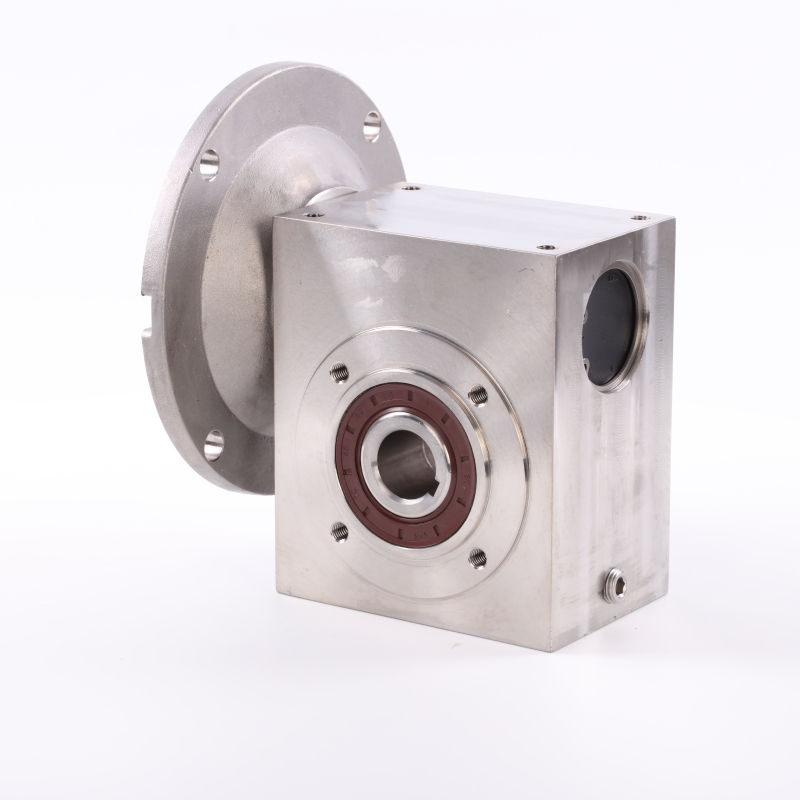

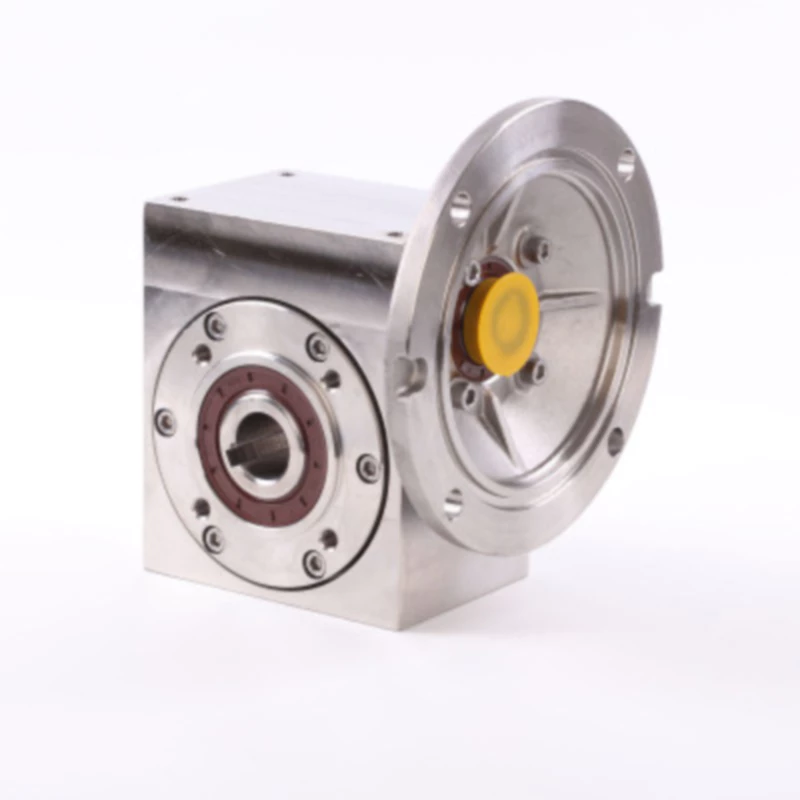

1. Overview of Stainless Steel Worm Gear Reducers

Stainless steel worm gear reducers are vital components in many industrial applications due to their durability and resistance to corrosion. These gear reducers are designed to provide precise speed reduction and torque multiplication in various machinery systems. They are commonly used in food processing, pharmaceutical, and chemical industries where cleanliness and hygiene are of utmost importance.

2. Composition and Design

Stainless steel worm gear reducers are constructed using high-quality stainless steel materials, ensuring excellent resistance to corrosion and wear. The design incorporates a worm gear and a worm wheel, which work together to transmit power and control rotational speed. The precision engineering of these components ensures smooth and efficient operation.

3. Benefits of Washdown Safe Gear Reducers

Washdown safe gear reducers offer several advantages in industrial settings. Their stainless steel construction allows for easy cleaning and sanitization, making them suitable for applications that require strict cleanliness standards. Additionally, these gear reducers exhibit high load capacity, low noise levels, and exceptional efficiency, contributing to enhanced performance and productivity.

4. Installation Process of Stainless Steel Worm Gear Reducers and Motors

The installation of stainless steel worm gear reducers and motors involves several key steps. Firstly, ensure that all components are clean and free from any contaminants. Then, carefully align the gear reducer and motor shafts, ensuring proper coupling connection. Secure the gear reducer and motor in place using appropriate fastening mechanisms. Finally, test the system to ensure smooth operation and make necessary adjustments if required.

5. Common Issues and Troubleshooting

While stainless steel worm gear reducers are reliable, there are some common issues that may arise during operation. Here are a few examples and their respective solutions:

| Issue | Solution |

|---|---|

| Excessive noise | Check for misalignment or worn gears. Lubricate the gears or replace if necessary. |

| Overheating | Ensure proper lubrication and ventilation. Check for any obstructions or excessive loads. |

| Leakage | Inspect seals and gaskets for damage. Replace if needed. Verify proper sealing. |

6. Stainless Steel Geared Motors for Sale

Stainless steel geared motors play a crucial role in various industrial applications, working in tandem with gear reducers to provide efficient power transmission. These motors are specifically designed to withstand harsh environments and maintain optimal performance in demanding conditions. At our company, we offer a wide range of stainless steel motors for sale, catering to diverse customer needs.

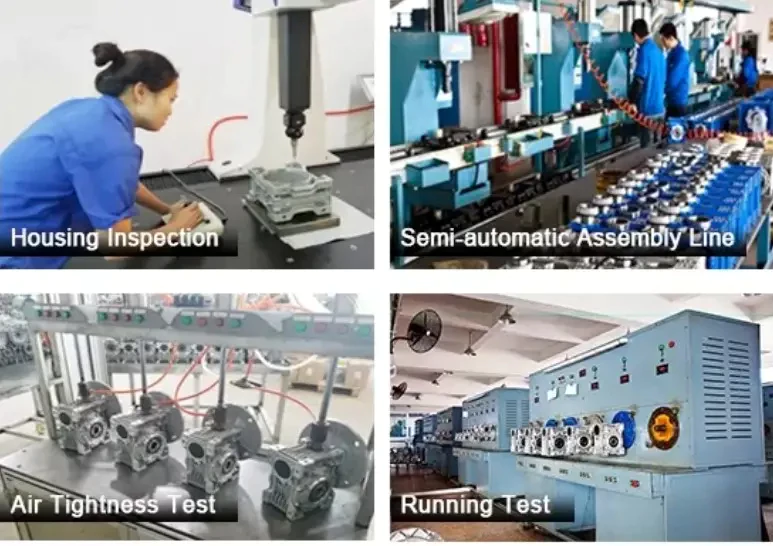

7. About Us

RP Techniek BV is the Netherlands sales agent of Ever-power Group, a renowned manufacturer of stainless steel worm gear reducers. With our strong production capabilities and a prestigious clientele in Europe and the Americas, we take pride in providing top-notch services, superior product quality, and competitive prices. We encourage customers to explore our range of products and contact us for their purchasing needs.

8. Q&A

Q1. What is the maximum load capacity of stainless steel worm gear reducers?

A1. The maximum load capacity of stainless steel worm gear reducers varies depending on the specific model and size. It is important to consult the product specifications provided by the manufacturer for accurate load capacity information.

Q2. Can stainless steel gear reducers be used in high-temperature environments?

A2. Yes, stainless steel gear reducers are designed to withstand high temperatures. However, it is crucial to select the appropriate model that is specifically rated for the desired temperature range to ensure optimal performance and longevity.

Q3. Are washdown safe gear reducers suitable for use in the food industry?

A3. Absolutely! The washdown safe feature of these gear reducers makes them ideal for use in the food industry where regular cleaning and sanitization are essential. Their stainless steel construction ensures compliance with hygiene standards.

Q4. Can stainless steel geared motors be customized to specific requirements?

A4. Yes, our company offers customization options for stainless steel geared motors. We understand that each application may have unique specifications, and we strive to provide tailored solutions to meet our customers' specific needs.

Q5. How can I purchase stainless steel worm gear reducers and motors from your company?

A5. To purchase stainless steel worm gear reducers and motors from our company, please contact our sales team through the provided contact information on our website. They will assist you in selecting the appropriate products and guide you through the purchasing process.

Edited by: Zqq.