In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and durability of conveying systems. This article will explore in depth the various applications and advantages of CC600 Crate Conveyor Chain in Amsterdam in the field of logistics automation, helping you better understand its value in efficient operation.

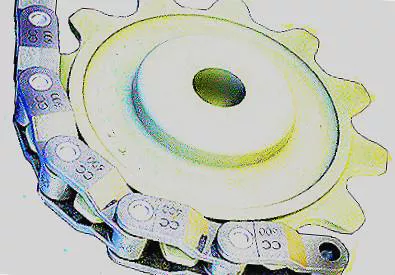

What is CC600 Crate Conveyor Chain in Amsterdam

CC600 Crate Conveyor Chain is a chain system designed for heavy-load and high-frequency operation, and is widely used in food and beverage, warehousing and distribution, plastic basket conveying and automated sorting lines. in logistics hub cities like Amsterdam, CC600 Crate Conveyor Chain in Amsterdam provides efficient delivery solutions for local warehousing and distribution.

This chain is made of high-strength engineering plastics or alloy materials, featuring excellent wear resistance, corrosion resistance and low maintenance costs. Especially in environments with low temperature and high humidity such as Amsterdam, its performance advantages are more obvious.

Main application scenarios of CC600 Crate Conveyor Chain in Amsterdam

Warehouse automation system

In large warehouses or distribution centers, especially the cross-border logistics center in Amsterdam, CC600 Crate Conveyor Chain is widely used for the efficient transportation of plastic baskets or containers. This chain can remain stable during long-term and high-frequency operation, ensuring that items are quickly and accurately transported from one area to another and enhancing the overall logistics efficiency.

The food and beverage industry

In the food and beverage industry, hygiene standards are extremely high. The corrosion resistance and easy-to-clean structure of CC600 Crate Conveyor Chain make it an ideal choice. For example, in local breweries or dairy processing plants in Amsterdam, this chain can stably transport heavy plastic baskets, reducing production stagnation.

Automatic sorting system

For logistics systems that require automatic identification and sorting of different goods, CC600 crate conveyor chain in Amsterdam can provide precise positioning and smooth delivery routes, combined with sensors and control systems to achieve efficient sorting, reduce labor costs and improve accuracy.

Technical advantages of CC600 Crate Conveyor Chain in Amsterdam

Durability and stability

CC600 crate conveyor chain is made of polymer or alloy steel and has extremely high mechanical strength and impact resistance. Even in a logistics environment like Amsterdam with heavy traffic and dense operations, it can maintain stable operation and avoid jamming and interruption.

Low maintenance cost

Thanks to its structural design and material advantages, the CC600 Crate Conveyor Chain requires no frequent lubrication or replacement, significantly reducing maintenance frequency and cost and extending the equipment life cycle. This means lower operating costs and higher production efficiency for local enterprises in Amsterdam.

Modular design

The chain adopts a modular structure. Each link of the chain can be replaced separately as needed, which improves the maintenance efficiency, shortens the system downtime, enhances the flexibility and scalability of the system, and is particularly suitable for industrial environments like Amsterdam where multiple business forms coexist.

Why Choose CC600 Crate Conveyor Chain in Amsterdam?

Today, with the rapid development of logistics automation, especially in international logistics hubs like Amsterdam, choosing the appropriate conveyor chain is of vital importance. CC600 crate conveyor chain not only meets the requirements of complex applications in terms of performance, but also has significant advantages in cost control and sustainable operation. Whether it is to enhance system efficiency or extend the service life of equipment, it is a reliable conveying solution for Amsterdam enterprises.

Conclusion

CC600 crate conveyor chain is an integral part of modern logistics automation systems. With its outstanding durability, stability and modular advantages, this chain has been widely applied in multiple industry fields. In cities like Amsterdam, the growing demand for CC600 crate conveyor chain provides a strong boost to improving local and international logistics efficiency.

When choosing a conveying system, enterprises should have a thorough understanding of the performance and application scenarios of different chain products to ensure the efficient, safe and economic operation of the system. If you are looking for high-performance Conveyor Chain products in Amsterdam, CC600 Crate Conveyor chain is undoubtedly the best option to consider.