Introduction

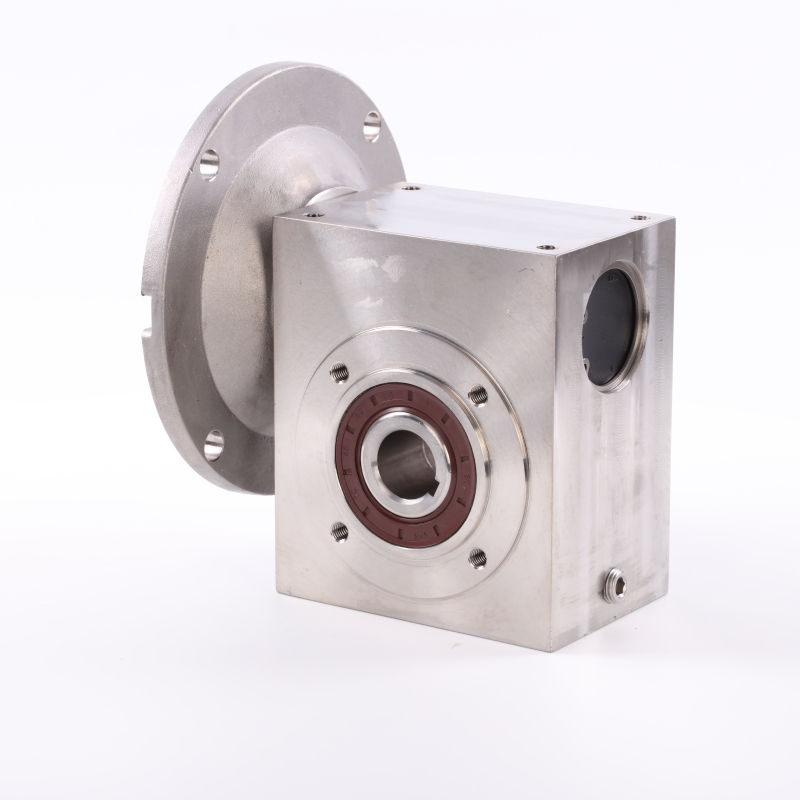

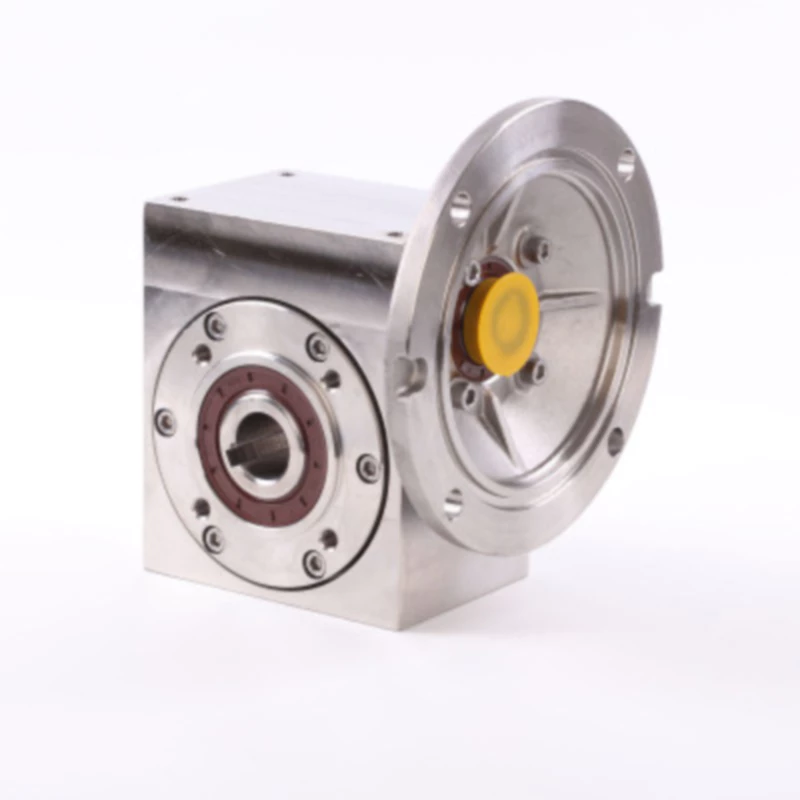

Industrial washdown worm gearbox is a precision-engineered machine that is widely used in the food processing, pharmaceutical, and chemical industries. It features a stainless steel housing that is resistant to corrosion and chemicals, making it suitable for use in harsh environments. In this blog post, we will discuss the various applications of industrial washdown worm gearbox in Dusseldorf, Germany.

Food Processing Industry

The food processing industry is one of the largest users of industrial washdown worm gearbox. It is used in various processes, including mixing, blending, and conveying. The gearbox is designed to withstand the harsh cleaning process that is required in the food industry. It can be cleaned using high-pressure water jets, and the stainless steel housing ensures that it does not rust or corrode.

Conveying

The industrial washdown worm gearbox is commonly used in conveying systems in the food processing industry. It is designed to provide a smooth and efficient transfer of products from one point to another. Its compact size allows it to be easily integrated into existing conveyor systems.

Mixing and Blending

The gearbox is also used in mixing and blending processes. It can handle various viscosities of products and ensures that the ingredients are mixed thoroughly. The stainless steel housing ensures that the gearbox remains hygienic and does not contaminate the products.

Pharmaceutical Industry

The pharmaceutical industry is another major user of industrial washdown worm gearbox. The gearbox is used in various processes, including tablet coating, granulation, and mixing. The stainless steel housing ensures that the gearbox remains hygienic and does not contaminate the products.

Tablet Coating

The industrial washdown worm gearbox is used in tablet coating machines. It ensures that the coating is distributed evenly on the tablets, and the stainless steel housing ensures that it remains hygienic and does not contaminate the products.

Granulation

The gearbox is also used in the granulation process, which involves mixing various powders and granules. The gearbox ensures that the ingredients are mixed thoroughly, and the stainless steel housing ensures that it remains hygienic and does not contaminate the products.

Chemical Industry

The chemical industry is another major user of industrial washdown worm gearbox. The gearbox is used in various processes, including mixing, blending, and conveying. The stainless steel housing ensures that the gearbox remains corrosion-resistant and does not react with the chemicals.

Mixing and Blending

The industrial washdown worm gearbox is commonly used in mixing and blending processes in the chemical industry. It ensures that the ingredients are mixed thoroughly, and the stainless steel housing ensures that it remains corrosion-resistant.

Conveying

The gearbox is also used in conveying systems in the chemical industry. It provides a smooth and efficient transfer of products from one point to another, and the stainless steel housing ensures that it remains corrosion-resistant.

Stainless Steel Geared Motors for Sale

The industrial washdown worm gearbox and the motor work together to provide a complete solution for various applications. The motor provides the power to the gearbox, which in turn drives the application. At RP Techniek BV, we offer a range of stainless steel motors and industrial washdown worm gearbox for sale. Our products are designed to meet the highest quality standards and provide reliable performance in harsh environments.

About Us

RP Techniek BV is the official sales agent for Ever-power Group in the Netherlands. We offer a range of industrial washdown worm gearbox and stainless steel motors that are designed to meet the highest quality standards. Our products are used by some of the largest companies in Europe and North America and are known for their reliability and performance. We are committed to providing our customers with the best products and services at competitive prices.

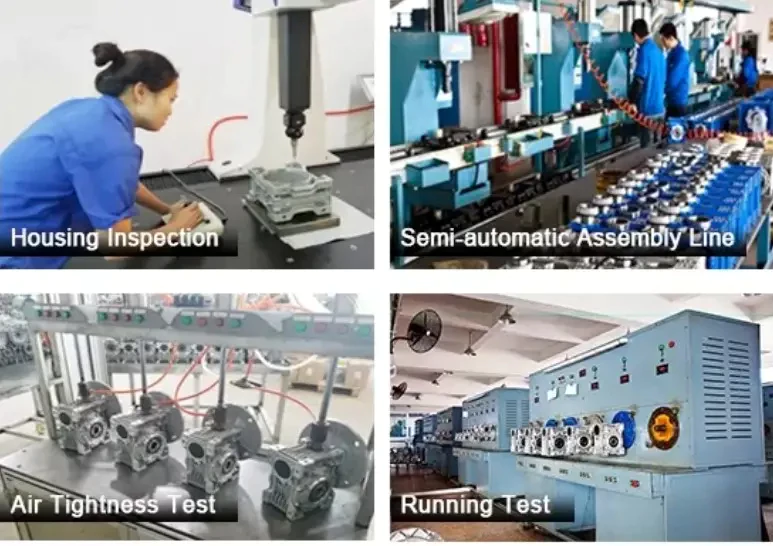

Installation of Stainless Steel Worm Gearbox and Motor

The installation of the stainless steel worm gearbox and motor should be carried out by trained professionals. The gearbox and motor must be mounted securely to ensure that they do not vibrate or move during operation. The electrical connections should be made by a licensed electrician to ensure that they are safe and comply with local electrical codes.

Common Problems and Solutions

| Problem | Solution |

|---|---|

| Overheating | Check the lubrication system and ensure that the gearbox is properly lubricated. If the problem persists, check the motor for faults. |

| Noise | Check the alignment of the gearbox and motor. If the problem persists, check the bearings for wear and tear. |

| Leaking | Check the seals and gaskets for damage. Replace any damaged components. |

| Vibration | Check the mounting of the gearbox and motor. Ensure that they are securely mounted and not loose. |

| Low Efficiency | Ensure that the gearbox and motor are properly maintained and lubricated. Check for any worn or damaged components and replace them if necessary. |

Stainless Steel Gearbox Q&A

Q: What is an industrial washdown worm gearbox?

A: An industrial washdown worm gearbox is a precision-engineered machine that is widely used in the food processing, pharmaceutical, and chemical industries. It features a stainless steel housing that is resistant to corrosion and chemicals, making it suitable for use in harsh environments.

Q: What are the applications of industrial washdown worm gearbox in Dusseldorf?

A: The industrial washdown worm gearbox is used in various applications in Dusseldorf, including mixing, blending, conveying, granulation, and tablet coating in the food processing, pharmaceutical, and chemical industries.

Q: What is the importance of the motor in conjunction with the gearbox?

A: The motor provides the power to the gearbox, which in turn drives the application. The motor and gearbox work together to provide a complete solution for various applications.

Q: What kind of problems can occur with the gearbox?

A: Some common problems with the gearbox include overheating, noise, leaking, vibration, and low efficiency.

Q: How can I ensure that the gearbox and motor are properly installed?

A: The gearbox and motor should be installed by trained professionals. The electrical connections should be made by a licensed electrician to ensure that they are safe and comply with local electrical codes. The gearbox and motor must be mounted securely to ensure that they do not vibrate or move during operation.