Introduction

A drop forged rivetless chain is an essential component in various industrial applications, providing a reliable and efficient means of conveying heavy loads. In this article, we will delve into the inner workings of a drop forged rivetless chain, exploring its design, functionality, and applications.

Understanding Drop Forged Rivetless Chains

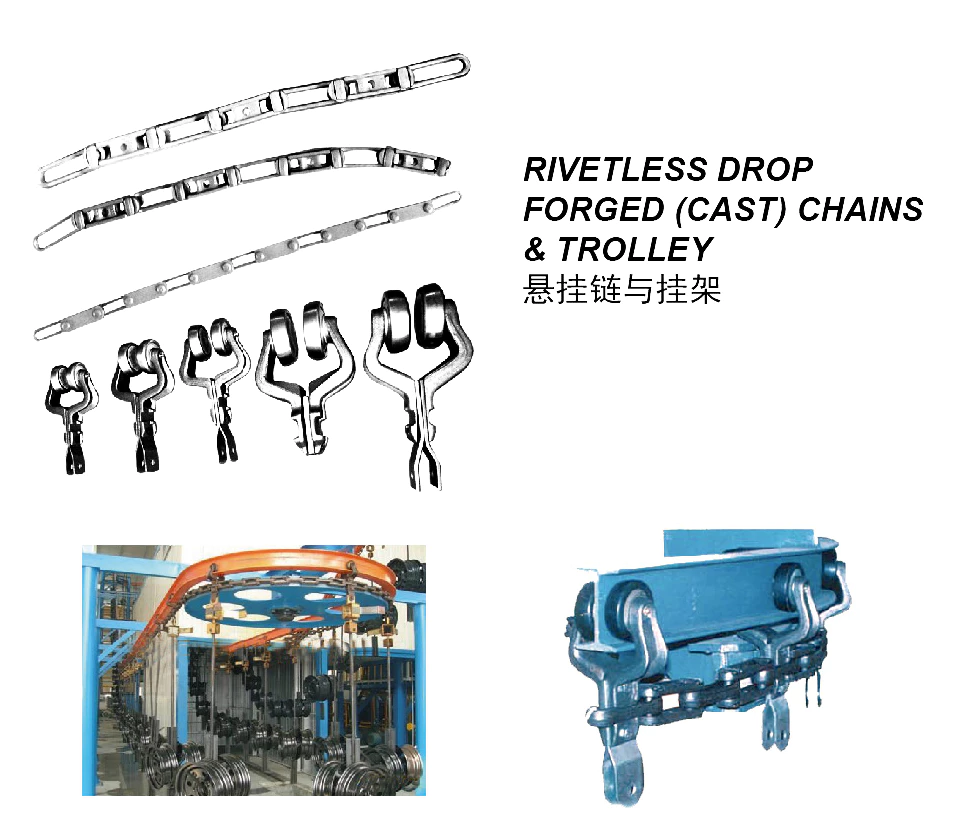

A drop forged rivetless chain is a type of chain that is commonly used in overhead conveyors and material handling systems. Unlike traditional roller chains, a drop forged rivetless chain does not utilize pins and bushings. Instead, it consists of interlocking links that are connected through a forged steel sidebar.

1. Composition and Structure

The drop forged rivetless chain is typically made from high-quality alloy steel, such as 40Cr, 20CrMnTi, or 42CrMo. This ensures its strength, durability, and resistance to wear and tear. The chain consists of a series of links, including inner links, outer links, and sidebar links.

2. Functionality and Operation

The drop forged rivetless chain operates by engaging with sprockets to create continuous motion. As the sprockets rotate, the chain moves along the conveyor, carrying the load. The interlocking links and the forged steel sidebar provide stability and prevent the chain from separating during operation.

3. Applications

Drop forged rivetless chains are widely used in various industries, including automotive, agriculture, food processing, and manufacturing. They are commonly found in overhead conveyors, assembly lines, and heavy-duty material handling systems.

Benefits of Drop Forged Rivetless Chains

Drop forged rivetless chains offer several advantages over traditional roller chains:

1. High Load Capacity

Due to their robust design and high-quality materials, drop forged rivetless chains can withstand heavy loads without deformation or failure.

2. Increased Durability

The use of forged steel and precise manufacturing techniques ensures that drop forged rivetless chains have excellent durability and resistance to wear, extending their lifespan.

3. Smooth and Quiet Operation

The interlocking links and the absence of pins and bushings contribute to a smooth and quiet operation, minimizing noise and vibrations.

4. Easy Installation and Maintenance

Drop forged rivetless chains are designed for easy installation and maintenance, allowing for quick replacements and reducing downtime.

Drop Forged Rivetless Chain Sprockets

Sprockets play a crucial role in the operation of drop forged rivetless chains. They are specially designed to engage with the chain, ensuring a smooth and efficient transfer of power. The relationship between drop forged rivetless chains and sprockets is complementary, as both components rely on each other for optimal performance.

About Us

RP Techniek BV is the Netherlands sales agent of Ever-power Group. As a leading supplier of drop forged rivetless chains, we offer a wide range of products, including forged chains, conveyor chains, and detachable chains like X348, X458, X678, and X698. Our products can be custom-made according to your drawings or samples. We provide high-quality products made from materials like 40Cr, 20CrMnTi, and 42CrMo to meet your requirements. Our product line includes extended pitch chains and pusher chains to cater to different customer needs. We also manufacture special chains, pins, and plates upon request. Over 90% of our products are exported to markets such as the United States, Canada, Japan, South Korea, Brazil, and Australia. We are committed to offering competitive prices and excellent service.

Sprockets for Drop Forged Rivetless Chains

Drop forged rivetless chain sprockets are an integral part of any material handling system that utilizes these chains. They ensure smooth engagement and reliable power transmission, enabling the chains to function effectively. The combination of drop forged rivetless chains and sprockets is essential for the seamless operation of conveyor systems and other applications.

At RP Techniek BV, we offer a wide selection of drop forged rivetless chain sprockets to complement our chain offerings. Our sprockets are manufactured with precision from high-quality materials to ensure durability and optimal performance. Whether you require standard or custom sprockets, we have the expertise to meet your specific needs. Contact us today to explore our range of sprockets and enhance your material handling system.

Q&A – Frequently Asked Questions

Q1: What are the main advantages of using drop forged rivetless chains?

A1: Drop forged rivetless chains offer high load capacity, increased durability, smooth operation, and easy installation and maintenance.

Q2: What applications are drop forged rivetless chains commonly used in?

A2: Drop forged rivetless chains are widely used in industries like automotive, agriculture, food processing, and manufacturing, particularly in overhead conveyors and heavy-duty material handling systems.

Q3: How do drop forged rivetless chains differ from traditional roller chains?

A3: Drop forged rivetless chains do not use pins and bushings like roller chains. Instead, they consist of interlocking links connected by a forged steel sidebar.

Q4: What materials are drop forged rivetless chains made from?

A4: Drop forged rivetless chains are typically made from high-quality alloy steel, such as 40Cr, 20CrMnTi, or 42CrMo, ensuring strength and durability.

Q5: Can drop forged rivetless chains be customized?

A5: Yes, at RP Techniek BV, we offer custom-made drop forged rivetless chains based on your drawings or samples, allowing for tailored solutions to meet your specific requirements.

Edited by: Zqq.

“