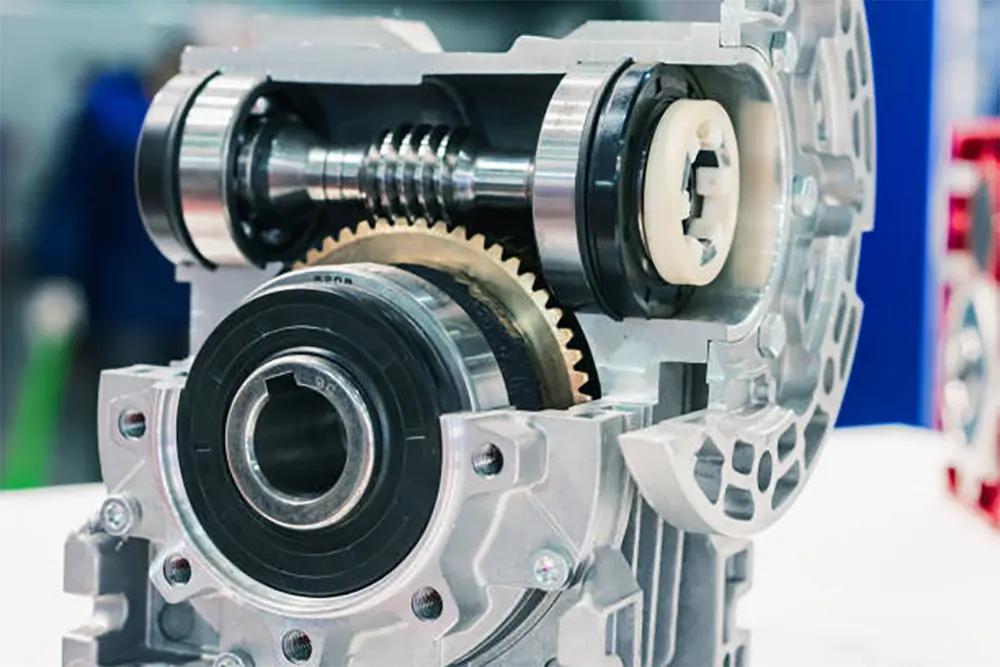

Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance. This article will systematically sort out five common types of problems and provide targeted solutions to help the equipment operate stably.

Abnormal wear and fracture of gears

Problem manifestation

Pitting, spalling, chipping or breakage of the gear tooth surface can lead to increased transmission noise, intensified vibration and even equipment shutdown.

Cause analysis

Lubrication failure: The extreme pressure and anti-wear performance of the lubricating oil is insufficient, unable to form a continuous oil film, resulting in direct contact with metals.

Overload impact: Sudden overloading or the entry of hard foreign objects into the meshing zone can cause local stress concentration in the gears.

Design defect: Improper selection of gear parameters, such as unreasonable design of module and pressure Angle, leads to insufficient fatigue strength at the tooth root.

Installation error: Poor parallelism of gear shafts and low contact accuracy cause eccentric load wear.

Solution

Optimize lubrication: Select extreme pressure anti-wear gear oil, regularly test the iron content and abrasive particles in the oil, and change the oil in a timely manner.

Control the load: Avoid frequent start-stop or impact loads, and install overload protection devices (such as torque limiters).

Improved design: Utilizing high-quality alloy steel for carburizing and quenching treatment, the tooth surface hardness is ≥60HRC, and the grinding accuracy reaches grade 5-6.

Precise installation: Use a laser alignment instrument to adjust the gear axis to ensure uniform distribution of contact spots.

Overheating and damage of bearings

Problem manifestation

When the bearing temperature exceeds 80℃, accompanied by abnormal noise or vibration, in severe cases, the bearing may get stuck.

Cause analysis

Insufficient lubrication: Blockage of the oil inlet hole, misalignment of the oil ring or insufficient oil quantity, resulting in a lack of oil in the bearing.

Improper clearance: The radial clearance of the bearing is too small, causing the rollers and raceways to be jammed.

Installation error: Excessive preload of the bearing, or excessive interference between the inner ring and the journal.

Contamination intrusion: Dust, moisture or metal debris entering the bearing accelerates wear.

Solution

Forced lubrication: Equipped with a gear pump forced oil injection system to ensure sufficient oil quantity and controllable oil temperature.

Adjust the clearance: Control the bearing clearance according to the manufacturer's standards (usually 0.15-0.25mm) and test it with a feeler gauge.

Standard installation: Use hydraulic installation tools to avoid damaging the bearings by knocking and control the interference fit.

Sealing protection: Select skeleton oil seals or labyrinth seals, and replace the sealing parts regularly.

Oil leakage from the gearbox

Problem manifestation

Oil leakage from the box joint surface, oil seal or observation window leads to a reduction in the amount of lubricating oil and environmental pollution.

Cause analysis

Seal aging: Hardening or cracking of sealing parts such as oil seals and O-rings.

Box deformation: The joint surface is uneven due to external force impact or casting defects.

Excessive pressure: The relief valve of the lubrication system malfunctions, and the oil pressure exceeds the limit.

Poor ventilation: The vent cap is clogged, and the air pressure inside the box increases.

Solution

Replace the seal: Select fluororubber or polytetrafluoroethylene seals and inspect and replace them regularly.

Repair the box: Weld the deformed parts or replace the box to ensure that the flatness of the joint surface is ≤0.1mm.

Pressure regulation control: Calibrate the pressure of the relief valve and install a pressure gauge for real-time monitoring.

Unclogging and ventilation: Clean the ventilation cap and install a breathing valve if necessary.

Abnormal Noise and Vibration

Problem manifestation

During the operation of the gearbox, periodic humming sounds, sharp friction sounds or metallic impact sounds are emitted, and the vibration value exceeds the standard.

Cause analysis

Poor gear meshing: Excessive or insufficient side clearance of the teeth, causing impact and vibration.

Shafting misalignment: The alignment deviation between the motor and the gearbox coupling exceeds the limit.

Loose components: Loose bolts, keys or pins can cause resonance.

Resonance phenomenon: The rotational speed approaches the critical speed, resulting in amplitude amplification.

Solution

Adjust meshing: Detect contact spots with red lead powder and grind the tooth surface to adjust the clearance.

Precision alignment: Use a laser alignment instrument to control the radial deviation to be ≤0.05mm and the angular deviation to be ≤0.05mm/m.

Fastening connection: Check and tighten all bolts, and use a torque wrench to lock them according to the standard values.

Vibration isolation design: Adjust the rotational speed to avoid the critical zone, or install damping vibration isolators.

Lubrication System failure

Problem manifestation

The lubrication pump fails to supply oil, has low pressure or abnormal oil temperature, resulting in insufficient lubrication of gears and bearings.

Cause analysis

Pump body failure: Mechanical pump shaft breakage, seal damage or check valve jamming.

Oil circuit blockage: Filter element blockage, oil pipe bending or scale accumulation in the cooler.

Oil temperature out of control: cooler failure, heater failure or extreme ambient temperature.

Electrical faults: Motor reverse rotation, line grounding or contactor damage.

Solution

Inspect the pump body: Replace the broken shaft and seals, and clean the check valve.

Clean the oil circuit: Regularly replace the filter element, unclog the oil pipe, and clean the cooler.

Temperature control modification: Install oil temperature sensors and heating/cooling modules to control the oil temperature within 40-65℃.

Electrical inspection: Check the motor rotation direction, circuit insulation and contactor contacts, and repair the fault points.

Summary

The stable operation of stainless steel gearboxes depends on the full-process control of design, installation, lubrication and maintenance. By optimizing gear parameters, strengthening the lubrication system, precisely installing and commissioning, and conducting regular condition monitoring, the failure rate can be significantly reduced. It is recommended to establish a preventive maintenance plan, integrating advanced technologies such as vibration analysis and oil detection, to achieve a shift from “post-event maintenance” to “pre-event prevention”, ensuring the long-term efficient operation of the equipment.