Introduction

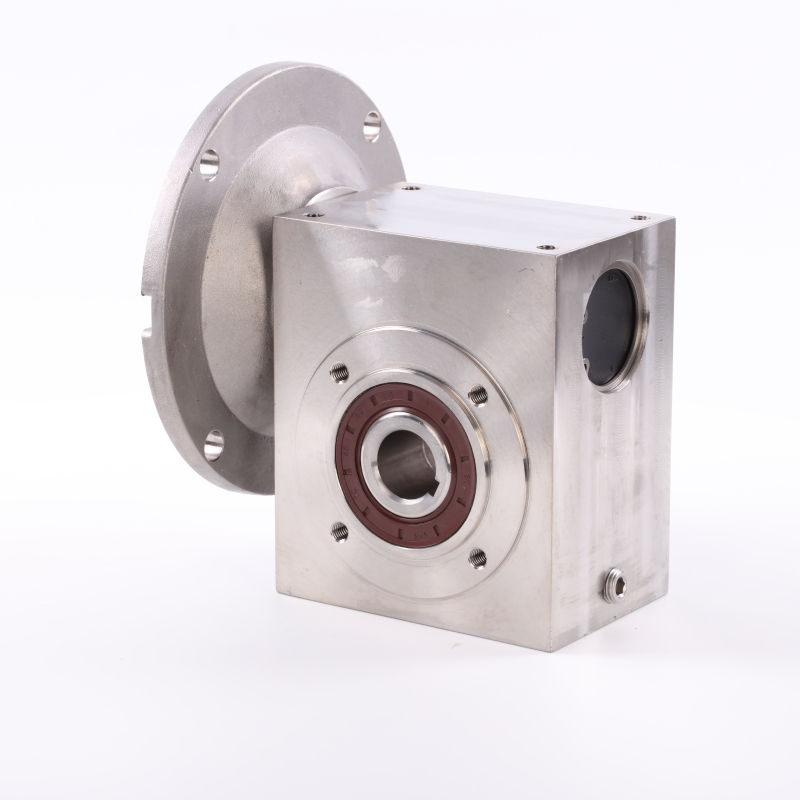

The food industry in Rotterdam demands high-quality and durable machinery to ensure smooth operations and compliance with safety standards. One crucial component is the corrosion-resistant worm gearbox, which plays a vital role in various food processing applications. In this article, we will explore the features, benefits, and installation process of stainless steel worm gearboxes, along with common issues and solutions.

Understanding Corrosion Resistance

The Importance of Stainless Steel in the Food Industry

When it comes to the food industry, maintaining a hygienic and contamination-free environment is paramount. Therefore, using corrosion-resistant materials, such as stainless steel, is crucial. Stainless steel possesses excellent resistance to corrosion, oxidation, and chemical exposure, making it an ideal choice for worm gearboxes in food processing.

Benefits of Corrosion-Resistant Worm Gearboxes

1. Extended Lifespan: Stainless steel worm gearboxes offer exceptional durability, ensuring long-term reliability in demanding food processing environments.

2. Hygiene and Cleanliness: The smooth surface of stainless steel prevents the build-up of bacteria, making it easier to clean and maintain proper hygiene standards.

3. Chemical Resistance: Stainless steel can withstand exposure to various chemicals used in the food industry, ensuring the gearbox's longevity and performance.

Installation Process of Stainless Steel Worm Gearboxes and Motors

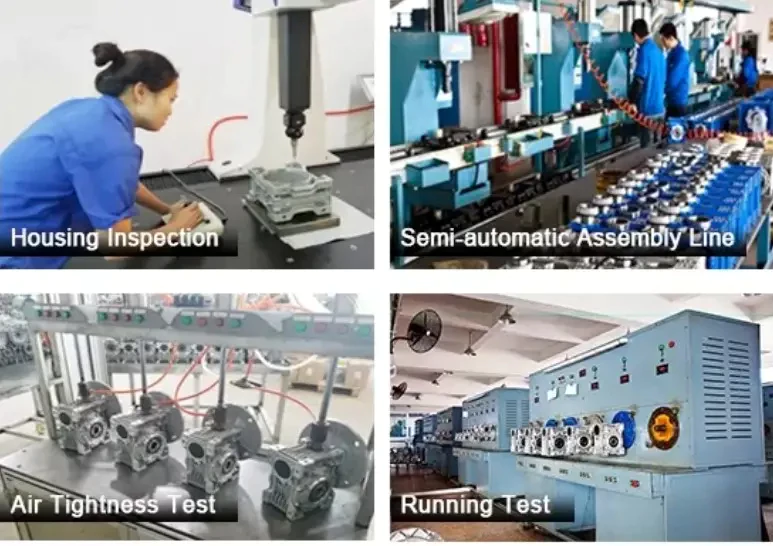

Installing a corrosion-resistant worm gearbox and motor requires careful attention to detail to ensure optimal performance and safety. Here is a step-by-step guide:

Step 1: Prepare the mounting surface by ensuring it is clean, level, and free from any debris.

Step 2: Align the gearbox and motor, ensuring proper shaft alignment and connection.

Step 3: Securely mount the gearbox and motor using suitable fasteners.

Step 4: Connect the electrical components, following all safety protocols and guidelines.

Step 5: Test the gearbox and motor to ensure smooth operation and functionality.

Step 6: Regularly inspect and maintain the gearbox and motor to prevent any potential issues.

Common Issues and Solutions

| Problem | Solution |

|---|---|

| Gearbox Overheating | Ensure proper lubrication and ventilation. Check for any obstructions or mechanical issues. |

| Noise and Vibration | Inspect gears for damage or misalignment. Adjust or replace components as necessary. |

| Leakage of Lubricant | Check seals and gaskets for damage. Replace faulty components and ensure proper lubrication. |

| Irregular Gearbox Operation | Inspect electrical connections and controls. Calibrate or replace any malfunctioning components. |

| Excessive Wear and Tear | Maintain regular maintenance schedules. Replace worn-out gears or bearings promptly. |

Stainless Steel Geared Motors for Sale

The relationship between gearboxes and motors in the food industry is symbiotic. A reliable and efficient gearbox, like the corrosion-resistant worm gearbox, is essential for achieving optimal motor performance. The gearboxes transmit torque and power from the motor to the food processing equipment, ensuring smooth and precise operation.

About Us

RP Techniek BV is the Netherlands sales agency of the Ever-power Group. We specialize in providing high-quality stainless steel worm gearboxes and motors to the food industry in Rotterdam. Our production capabilities, coupled with our dedication to customer satisfaction, have earned us a reputable position in the European and American markets. We strive to offer the best services, highest product quality, and competitive pricing to our esteemed clients.

Explore our range of products and experience the excellence of our stainless steel worm gearboxes and motors. Contact us today to make a purchase and elevate your food processing operations to the next level.

Q&A

Q: Is stainless steel the only material used for corrosion-resistant gearboxes?

A: While stainless steel is a popular choice, there are other materials available, such as aluminum or coated metals, that can provide corrosion resistance based on specific requirements.

Q: Can I use a regular gearbox instead of a corrosion-resistant one in the food industry?

A: It is highly recommended to use corrosion-resistant gearboxes specifically designed for the food industry to ensure compliance with safety and hygiene standards.

Q: What maintenance practices should be followed for stainless steel worm gearboxes?

A: Regular inspection, proper lubrication, and prompt replacement of worn-out components are essential for maintaining the performance and longevity of stainless steel worm gearboxes.

Q: Can the stainless steel worm gearbox be customized to fit specific equipment?

A: Yes, our company offers customization services to meet the unique requirements of our clients, ensuring seamless integration with their food processing equipment.

Q: How can I contact RP Techniek BV to inquire about purchasing corrosion-resistant worm gearboxes and motors?

A: You can reach out to us through our website or contact our sales team directly via phone or email. We are always ready to assist you with your inquiries and provide the necessary information regarding our products and services.

Edited by: Zqq.