Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

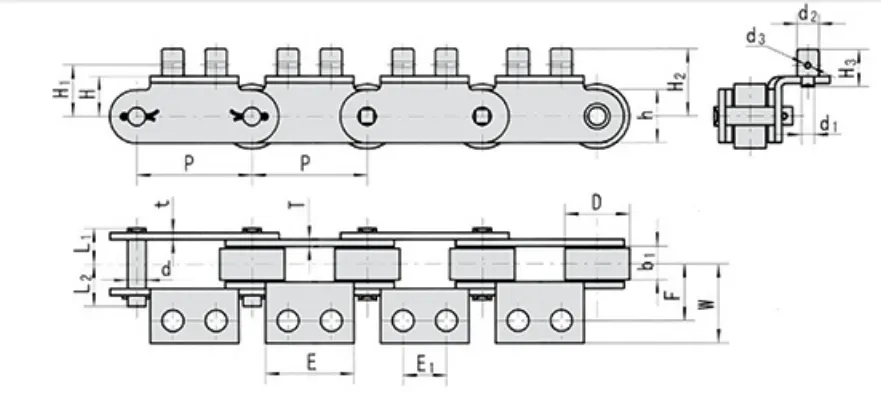

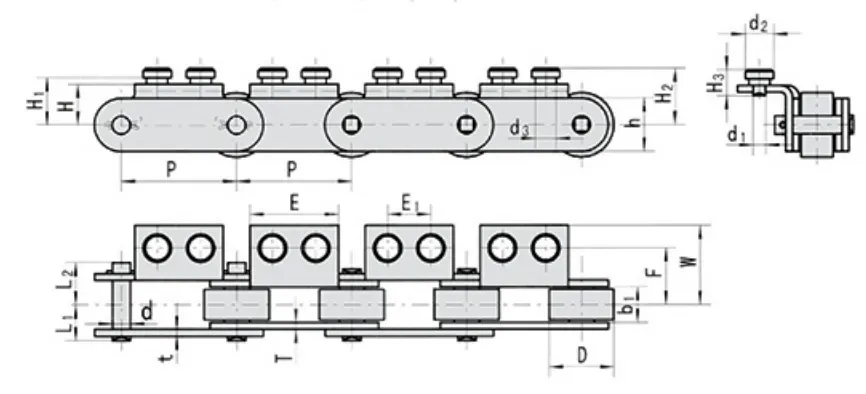

Dimensions

The C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain has the following parameters:

- Chain pitch: C216AL

- Attachments: K2ZB

- Material: Stainless steel

- Application: Ice-cream processing

| E1 | E | F | W | H | H1 | H2 | H3 | d1 | d2 | d3 | ||

| Chain No | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Type |

| C216AL-K2ZB-RSS | 19.1 | 39 | 25.5 | 35.5 | 18 | 23 | 30 | 16.5 | 6.6 | 9.5 | 2.5 | I |

| C216AL-K2ZB-LSS | 19.1 | 39 | 25.5 | 35.5 | 18 | 21 | 25 | 11.5 | 6.6 | 12.5 | 9.3 | II |

| C216AL-SK2-N1SS | 19.05 | 39 | 28.18 | 38.73 | 19.05 | ¡ª¡ª | 31.75 | 17.2 | 6.6 | 9.5 | ¡ª¡ª | I |

| C216AL-SK2-N1SS | 19.05 | 39 | 28.18 | 38.73 | 19.05 | 22.05 | 26.05 | 11.5 | 6.6 | 12.5 | 9.3 | II |

| C63.5S-RSS | 25 | 47 | 25.5 | 36 | 24 | 29.5 | 36 | 16.5 | 6.6 | 9.5 | 2.5 | I |

| C63.5S-LSS | 25 | 47 | 25.5 | 36 | 24 | 27.5 | 31.5 | 12 | 6.6 | 12.5 | 9.3 | II |

| C63.5S-N2SS | 25 | 47 | 25.5 | 36 | 18 | 23.5 | 30 | 16.5 | 6.6 | 9.5 | 2.5 | I |

| C63.5S-N1SS | 25 | 47 | 25.5 | 36 | 18 | 21.5 | 25.5 | 12 | 6.6 | 12.5 | 9.3 | II |

| Chain No. |

Pitch | Width between inner plates |

Roller? diameter | Pin | Plate | UItimate tensile strength | Type | |||

| P | bl(min) | D(max) | d | L1 | L2 | h | t/T | Q(min) | ||

| mm | mm | mm | mm | mm | mm | mm | mm | KN | ||

| C216AL-K2ZB-RSS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | I |

| C216AL-K2ZB-LSS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | II |

| C216AL-SK2-N1SS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | I |

| C216AL-SK2-N1SS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | II |

| C63.5S-RSS | 63.5 | 15.75 | 39.68 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | I |

| C63.5S-LSS | 63.5 | 15.75 | 39.68 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | II |

| C63.5S-N2SS | 63.5 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | I |

| C63.5S-N1SS | 63.5 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | II |

Introduction

The C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain is a vital component in the ice-cream manufacturing process. It is designed to handle the rigorous demands of ice-cream processing, including transporting, cooling, and freezing ice-cream ingredients. In this comprehensive guide, we will take a closer look at the features, benefits, and applications of the C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain.

Features

Stainless Steel Material

The C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain is made of high-quality stainless steel. This material is corrosion-resistant and can withstand the harsh conditions of ice-cream processing. It also ensures that the chain is durable and long-lasting.

Metallic Bushing

The chain features a metallic bushing that reduces friction between the chain and sprocket. This feature helps to extend the life of the chain and improve efficiency during the ice-cream manufacturing process.

Wide Temperature Range

The C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain can operate in a wide temperature range, from -40¡ãC to 150¡ãC. This makes it ideal for use in freezers, coolers, and other ice-cream processing equipment.

Low Noise

The chain is designed to produce low noise levels during operation. This reduces noise pollution in the production facility and creates a more comfortable working environment for employees.

Easy to Clean

The C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain is easy to clean, which is essential in food processing applications. Its smooth surface and lack of crevices make it easy to remove any residues and maintain a high level of hygiene.

Benefits

Improved Efficiency

The C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain is designed to improve efficiency during the ice-cream manufacturing process. Its low noise levels, reduced friction, and wide temperature range help to improve productivity and reduce downtime.

Long-lasting Durability

The use of high-quality stainless steel and metallic bushing in the chain ensures that it is durable and long-lasting. This reduces the need for frequent replacements, saving time and money in the long run.

Enhanced Hygiene

The easy-to-clean design of the C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain helps to maintain a high level of hygiene in the production facility. This is important in food processing applications where hygiene is critical for product quality and safety.

Reduced Maintenance Costs

The durability of the chain and its low maintenance requirements help to reduce maintenance costs. This is beneficial for businesses looking to improve their bottom line and remain competitive in the ice-cream manufacturing industry.

Applications

The C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain is ideal for use in a variety of ice-cream manufacturing applications, including:

- Transporting ice-cream ingredients

- Cooling and freezing ice-cream mixtures

- Moving ice-cream containers along the production line

- Conveying ice-cream products to packaging and storage areas

Conclusion

The C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain is a vital component in the ice-cream manufacturing process. Its features, benefits, and applications make it an ideal choice for businesses looking to improve efficiency, reduce maintenance costs, and maintain a high level of hygiene in their production facilities. With its use of high-quality materials and innovative design, the C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain is a reliable and long-lasting solution for ice-cream manufacturers.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV, proudly appointed as the official sales agent for Ever-power Group in the Netherlands, offers a wide range of high-quality stainless steel roller chains for various industries. Our C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain is a unique product that stands out from the crowd.

Our stainless steel roller chains are manufactured from the finest raw materials using state-of-the-art technology. They offer superior resistance to corrosion, heat, and chemical reactions, making them ideal for use in harsh environments. Furthermore, our chains are precision-engineered to offer exceptional performance and durability, ensuring long service life and reduced downtime.

At RP Techniek BV, we strive to provide our clients with the highest standards of service and support. Our team of seasoned professionals is always ready to assist you in selecting the most suitable products for your applications and needs. We also offer custom solutions to meet your specific requirements.

Beside C216AL-K2ZB-LSS Stainless Steel Ice-cream Processing Chain, we also offer other types of stainless steel roller chains for various industries such as food processing, packaging, and many more. With our extensive knowledge and experience in the field, we are confident in providing you with the best quality products and services.

Please find below the image of our manufacturing facility.

Sprockets for Sale

When it comes to finding the perfect chain sprocket to pair with your C216AL-K2ZB-LSS stainless steel ice-cream processing chain, look no further than our selection of high-quality sprockets. Our company offers a wide range of different types of sprockets, each designed to meet the unique needs and specifications of your machinery.

Whether you are in need of a simple, standard sprocket or a more specialized option, we have you covered. Our sprockets are made from durable materials and are built to withstand even the most demanding applications. Plus, our sprockets are available in a variety of sizes and configurations, making it easy to find the perfect match for your chain.

At our company, we are committed to providing our customers with the highest level of service and support. That's why we offer fast shipping, competitive pricing, and expert advice to help you find the right sprocket for your needs. So why wait? Browse our selection of sprockets today and find the perfect match for your C216AL-K2ZB-LSS stainless steel ice-cream processing chain.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...