Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Dimensions of 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain for Jelly Making Machine

The 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain, designed for jelly-making machines, includes the following specifications:

- Pitch: 12.7mm

- Roller diameter: 7.77mm

- Width between inner plates: 7.85mm

- Pin diameter: 3.96mm

- Chain plate height: 15.88mm

- Tensile strength: 8.9kN

- Weight per meter: 1.49kg

| Chain No. |

Pitch | Width between inner plates |

Pin diameter |

Pin length |

Inner plate depth |

|||

| P | b1 | D | d2 | Lp | Lc | h2 | T | |

| min | max | max | max | max | max | max | ||

| mm | mm | mm | mm | mm | mm | mm | mm | |

| 12ASS-K2/A2wJn10.75BSS | 19.05 | 12.57 | 11.91 | 5.94 | 25.6 | 30.1 | 18.08 | 3 |

| Chain No. | h4 | f | g | d4 | w | U1 | U2 | |

| mm | mm | mm | mm | mm | mm | mm | ||

| 12ASS-K2/A2wJn10.75BSS | 10.75 | 41 | 19.05 | 6 | 57.4 | 34.6 | ||

1. Introduction to 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain

The 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain is engineered for high efficiency and durability, tailored specifically for jelly-making machinery. Its high-grade stainless steel construction offers remarkable strength, resistance to corrosion, and extended longevity.

2. Key Features of 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain

2.1 Superior Durability:

This chain is manufactured using cutting-edge techniques, ensuring exceptional durability. It is capable of supporting heavy loads, enduring high temperatures, and withstanding challenging operating environments, guaranteeing dependable performance during jelly production.

2.2 Resistance to Corrosion:

Due to its stainless steel makeup, this chain shows outstanding resistance to corrosion from moisture, acids, and other chemicals frequently found in jelly manufacturing. It remains unharmed by corrosive conditions, thus extending its lifespan and reducing maintenance efforts.

2.3 Efficient Operation:

The chain is designed to minimize friction and features optimized internal lubrication pathways, enabling smooth and effective operation. This leads to decreased energy use, enhanced productivity, and lower wear, contributing to overall savings and improved production efficiency.

3. Application of 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain

3.1 Jelly Production Machinery:

This chain is specifically crafted for jelly production machinery, where it is essential in conveying and transferring jelly ingredients throughout the manufacturing process. Its reliability, strength, and smooth functioning are vital for achieving consistent and high-quality jelly output.

4. Installation and Maintenance Guidelines

4.1 Installation Best Practices:

During the installation of the 12ASS-K2/A2wJn10.75BSS chain, it's crucial to ensure proper tensioning and alignment with the sprockets. Adhering to the manufacturer’s guidelines will provide optimal performance and prevent premature wear or damage.

4.2 Routine Maintenance:

To maintain the chain's longevity and efficiency, regular upkeep is necessary. This encompasses periodic lubrication, checking for signs of wear or damage, and timely replacement of any worn components. Following a recommended maintenance routine will maximize the chain’s operational life and support uninterrupted production.

5. Conclusion

The 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain represents an excellent option for jelly production equipment. Its remarkable durability, corrosion resistance, and smooth operation guarantee dependable and effective functioning in jelly manufacturing processes. By choosing this high-quality chain, producers can boost productivity, cut maintenance expenses, and deliver consistent, high-quality jelly products to their clients.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV, representing Ever-power Group in the Netherlands, takes pride in providing high-quality stainless steel roller chains. Our dedication to quality is reflected in our product offerings, including the 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain for Jelly Making Machine.

Our unique selling points are rooted in the remarkable quality and dependability of our stainless steel roller chains. Manufactured with precision, these chains are engineered to endure even the most challenging environments while offering smooth and effective operation.

At RP Techniek BV, we recognize the significance of exceptional customer service. Our team of professionals is committed to offering personalized support and advice, ensuring that our clients find the most suitable stainless steel roller chains for their specific requirements.

Moreover, we take pride in our robust manufacturing capabilities. Our advanced facilities and technologies allow us to produce stainless steel roller chains that align with the highest industry standards.

Alongside the 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain for Jelly Making Machine, we provide a comprehensive range of additional stainless steel roller chains for various uses. Our diverse selection guarantees that customers can discover the ideal chain for their unique needs.

Experience the reliability and performance of our stainless steel roller chains. Choose RP Techniek BV and witness the difference in quality and service.

Sprockets for Sale

For those looking for the perfect complement to the 12ASS-K2/A2wJn10.75BSS Stainless Steel Short Pitch Conveyor Chain for Jelly Making Machine, we offer an extensive selection of sprockets to fulfill your requirements.

Our sprockets are engineered with precision and durability in mind, ensuring seamless and effective operation of your machinery. Whether you need standard or customized sprockets, we have the right solution for you.

With our large inventory, we provide a variety of sprockets, including options made from different materials such as stainless steel, carbon steel, and plastic. Our sprockets come in various sizes and tooth configurations to suit different chain pitches and load demands.

We understand the importance of reliability and performance in operations. For this reason, we provide high-quality sprockets designed for longevity. Our knowledgeable team is dedicated to helping you find the right sprockets to enhance the efficiency and productivity of your jelly making machines.

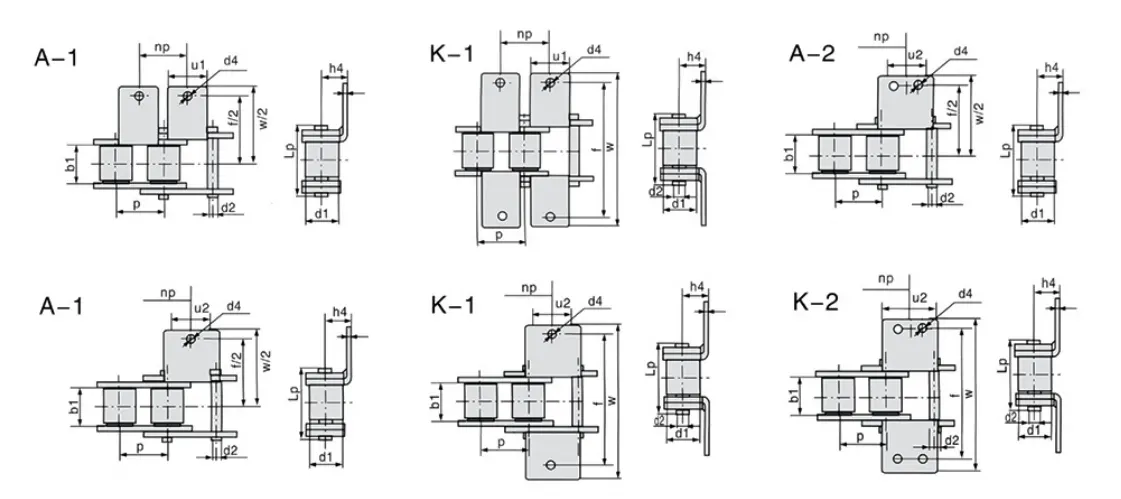

Check out the image below to explore our sprocket offerings:

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...