Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

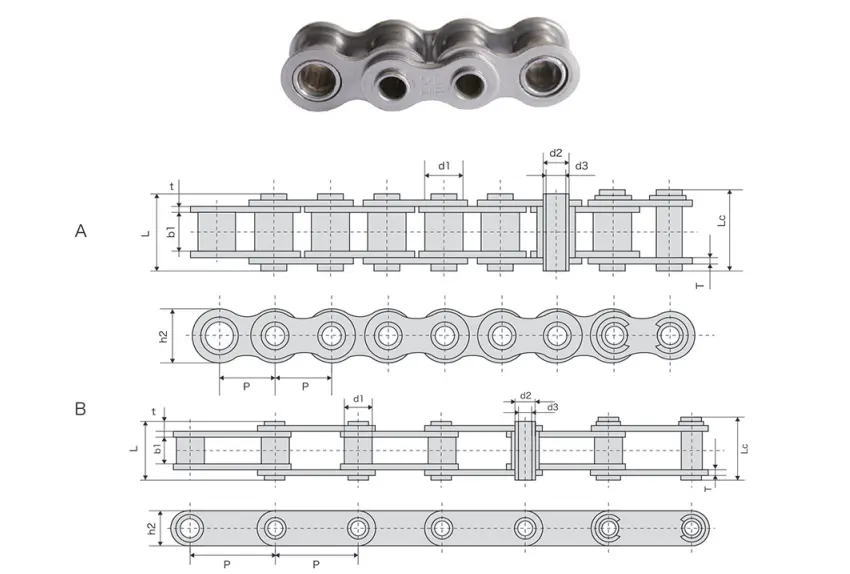

The 40HPSS Stainless Steel Hollow Pin Chain features several important specifications, making it suitable for various applications.

| Chain No |

Pitch | Bush? diameter | Width between inner plates |

Pin diameter |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

Breaking Load |

Weight per meter |

Type |

| P | d1 | bl | d2 | d3 | L | LC | h2 | T | Q | q | ||

| max | min | max | min | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | Mm | mm | mm | mm | KN | kg/m | ||

| 08BHPFSS | 12.7 | 8.51 | 7.75 | 6.55 | 4.5 | 16.4 | 17.6 | 11.8 | 1.5 | 7.8/1773 | 0.57 | A |

| 40HPSS | 12.7 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.55 | A |

| 50HPSS | 15.875 | 10.16 | 9.4 | 7.03 | 5.13 | 20.7 | 21.9 | 15.09 | 2 | 14.0/3182 | 0.92 | A |

| 60HPSS | 19.05 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 18 | 2.4 | 16.8/3818 | 1.31 | A |

| *12BHPSS | 19.05 | 12.07 | 11.68 | 6.5 | 4 | 21.6 | 22.8 | 15.9 | 1.8 | 16.5/3750 | 1.1 | A |

| 80HPSS | 25.4 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 2.29 | A |

| C2040HPSS | 25.4 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.47 | B |

| C2050HPSS | 31.75 | 10.16 | 9.4 | 7.22 | 5.12 | 20.5 | 21.8 | 15 | 2 | 14.3/3250 | 0.77 | B |

| C2060HPSS | 38.1 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 17 | 2.4 | 16.8/3818 | 1.03 | B |

| C2080HPSS | 50.8 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 1.83 | B |

| *HB50.8SS | 50.8 | 30 | 10.5 | 11.4 | 8.2 | 27.4 | 28.6 | 26 | 3 | 35.0/7955 | 2.6 |

Introduction

The 40HPSS Stainless Steel Hollow Pin Chain is engineered for heavy-duty use, made from high-quality stainless steel to ensure excellent resistance to both corrosion and wear. This precision roller chain is perfect for demanding applications requiring exceptional strength and durability under challenging conditions.

Features

This chain boasts a variety of features that make it ideal for heavy-duty applications. Key features include:

- Superior corrosion resistance thanks to high-grade stainless steel

- Precision design for enhanced strength and durability

- Hollow pin design that facilitates easy installation and maintenance

- Designed to handle high loads in harsh environments

- Versatile for use across many industries such as food processing, chemicals, and pharmaceuticals

Specifications

The 40HPSS Stainless Steel Hollow Pin Chain comes in multiple sizes to cater to diverse application needs. Key specifications include:

- Chain Pitch: 1/2 inch

- Plate Height: 0.63 inch

- Plate Thickness: 0.094 inch

- Pin Diameter: 0.20 inch

- Breaking Load: 7,400 lbs

Applications

This chain is widely utilized in a variety of heavy-duty applications across several industries. Common uses include:

- Conveyor systems

- Food processing machinery

- Bottling and packaging equipment

- Pharmaceutical manufacturing machinery

- Chemical processing machinery

Maintenance

The 40HPSS Stainless Steel Hollow Pin Chain is designed for straightforward maintenance. Regular cleaning and lubrication are essential to prolong the chain's lifespan and ensure peak performance. Regular inspections for wear or damage are recommended, with timely replacements when necessary.

Overall, the 40HPSS Stainless Steel Hollow Pin Chain is a premium, reliable choice for heavy-duty applications across various sectors. Its exceptional resistance to corrosion, along with its strength and durability, makes it a top selection for high-performance needs.

Choose Our Stainless Steel Roller Chains

RP Techniek BV serves as the authorized sales representative for Ever-power Group in the Netherlands. We proudly offer the outstanding 40HPSS Stainless Steel Hollow Pin Chain, exemplifying our distinctive advantages and the high quality of service we deliver. Our robust production capabilities guarantee that every chain adheres to the highest standards.

In addition to the 40HPSS Stainless Steel Hollow Pin Chain, we provide a broad array of other stainless steel roller chains. Our extensive inventory ensures you will find the ideal chain to meet your specific requirements. Whether you need durability, resistance to corrosion, or exceptional strength, our stainless steel roller chains guarantee reliability and performance.

At RP Techniek BV, we are committed to fulfilling our customers' needs while surpassing their expectations. Reach out to us today to learn how our stainless steel roller chains can improve your operations.

Sprockets for Sale

The 40HPSS Stainless Steel Hollow Pin Chain works best with our durable, high-quality sprockets. We offer a diverse selection of sprockets for various applications and specifications.

Our sprockets are engineered for optimal performance and reliability. Constructed from top-grade materials, they are designed to endure heavy loads, resist wear and corrosion, and provide long-lasting functionality.

Whether you're seeking standard sprockets, customized solutions, or specialized options, we have what you need. Our stock includes a variety of sizes, tooth configurations, and materials tailored to your requirements.

With our comprehensive range of sprockets, you can find the perfect complement for your 40HPSS Stainless Steel Hollow Pin Chain. Our knowledgeable team is available to guide you in selecting the right sprocket to ensure compatibility and peak performance.

Check out the image below to view an example of the sprockets we provide:

For further details and to explore our full range of sprockets, please contact us. We are dedicated to offering high-quality products along with excellent customer service to meet your needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...