In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

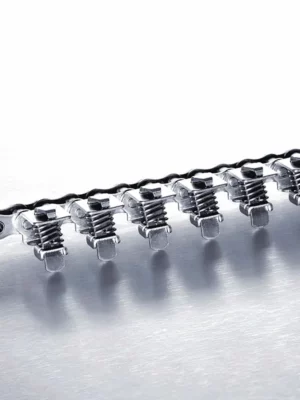

Introduction of Stainless Steel Roller Chains for Packing Machine

Stainless Steel Roller Chains designed for packing machines provide exceptional durability and are highly resistant to corrosion. These chains are engineered to endure the high humidity and acidic conditions that are commonly encountered in packaging environments. Constructed from premium stainless steel, they deliver outstanding strength and wear resistance, ensuring reliable and smooth operation even under challenging circumstances. Ideal for use in the food, beverage, and pharmaceutical sectors, these roller chains require minimal maintenance, leading to decreased downtime and extended service life.

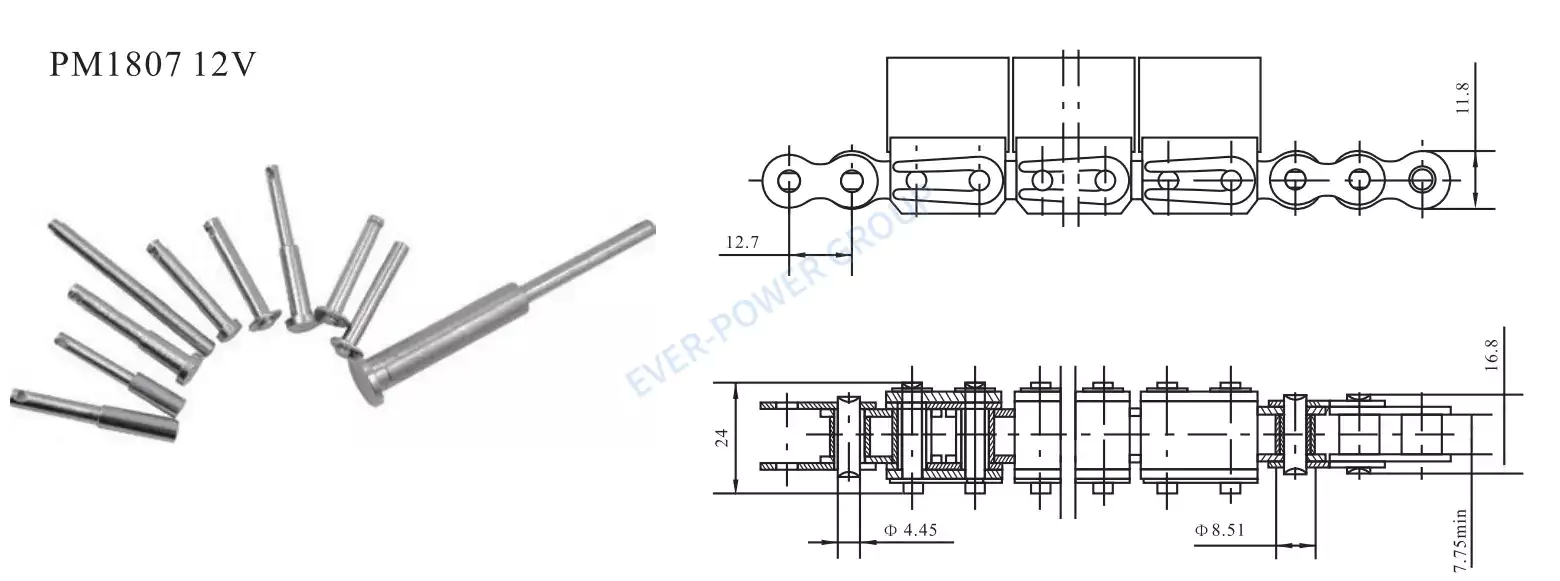

Packing Machine Stainless Steel Roller Chains Specifications

PM1807 12v

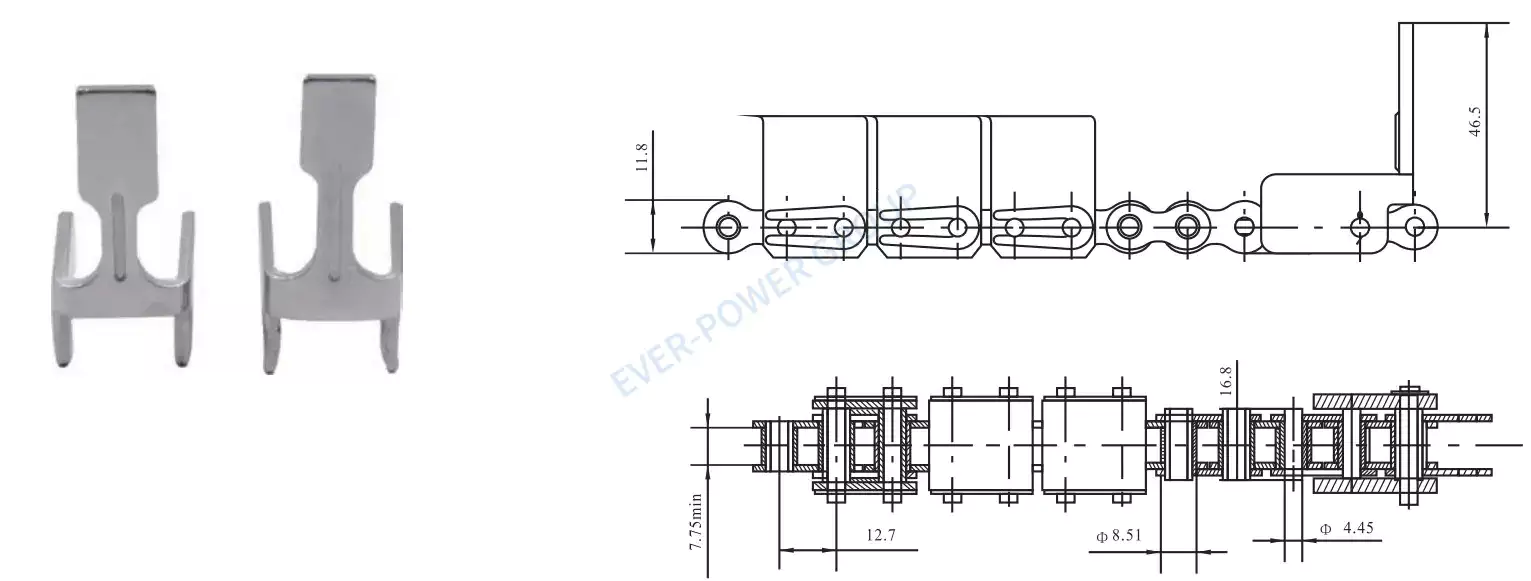

Packing Machine Fork Chain

Characteristics of Stainless Steel Packing Machine Roller Chains

Stainless Steel Roller Chains for packing machines come with several important features:

- Corrosion Resistance: Constructed from stainless steel, these chains possess a high level of resistance to rust and corrosion, making them perfect for wet, humid, and acidic settings.

- High Durability: The stainless steel build guarantees longevity and strength, allowing them to endure continuous use in challenging packaging conditions.

- Low Maintenance: Their corrosion resistance and durability mean that these chains need less maintenance, which reduces downtime and operational expenses.

- Temperature Tolerance: These stainless steel chains perform effectively across a broad temperature range, making them suitable for various packaging operations, including those in the food and pharmaceutical industries.

- Hygienic Design: The smooth finish of stainless steel helps prevent contamination, meeting the hygiene standards required in sectors such as food processing and pharmaceuticals.

- Reliable Performance: These chains ensure consistent functionality with minimal stretching or wear, promoting the efficient operation of packing machines over extended periods.

Stainless Steel Roller Chains offer a dependable solution that merges strength and cleanliness, crucial for the distinct needs of the packaging industry.

Sprockets for Sale

Stainless Steel Roller Chain Sprockets serve as vital components in packing machines, optimized to function seamlessly with stainless steel roller chains. These sprockets are crafted from robust stainless steel, providing outstanding resistance to corrosion, which is vital in high-moisture, humid, or chemically exposed environments, such as food, beverage, and pharmaceutical packaging facilities. Their sturdy design assures prolonged performance, decreasing wear and limiting the necessity for frequent replacements.

Stainless steel sprockets are engineered for smooth and efficient operation, enabling precise movement of roller chains, which is essential for high-speed packaging operations. They ensure proper alignment and tension, guaranteeing consistent and reliable machine performance. Furthermore, these sprockets help lower maintenance needs, as their corrosion-resistant nature minimizes contamination, making them easier to maintain.

Our company provides a diverse range of stainless steel sprockets to cater to various application requirements.

Additional information

| Edited by | Zqq. |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...