Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

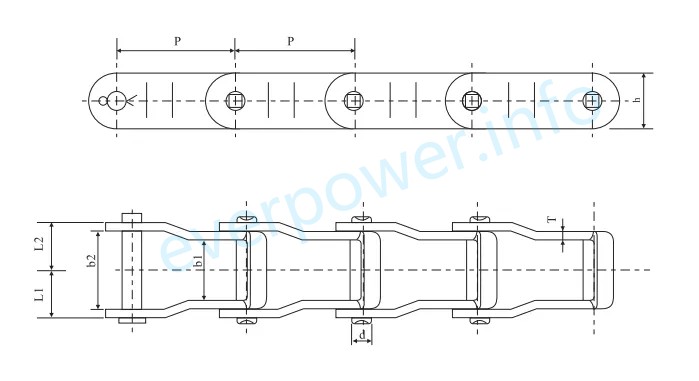

Specifications of 662H Stainless Steel Pintle Chain

The following information outlines the specifications for stainless steel pintle chains.

Introduction of 662H Stainless Steel Pintle Chain

The 662H Stainless Steel Pintle Chain is a robust and dependable chain utilized across a variety of industrial settings. Constructed from premium stainless steel, this chain delivers outstanding resistance to corrosion and impressive strength. Its distinctive design and superior material characteristics ensure reliable operation even in challenging environments. This chain is particularly well-suited for applications demanding durability and longevity.

Advantages of 662H Stainless Steel Pintle Chain

Our 662H stainless steel pintle chain presents numerous benefits compared to alternative chain types available in the market. One of its most significant advantages is its remarkable strength and durability. Made from high-grade stainless steel, this chain can endure extreme temperatures and severe operational conditions without succumbing to rust or corrosion.

Another key benefit of this chain is its exceptional resistance to wear. Its innovative design enables it to manage heavy loads and high-speed operations without failure or disassembly. This characteristic makes it a prime choice for applications where a dependable and robust chain is essential.

Moreover, our 662H stainless steel pintle chain demands minimal maintenance, a considerable advantage for businesses aiming to lower downtime and boost productivity. It is also straightforward to install and operates at a low noise level, making it suitable for a broad spectrum of industries.

Applications of 662H Stainless Steel Pintle Chain

- Food Processing Industry: The 662H Stainless Steel Pintle Chain is extensively used in food processing operations such as conveying, cooling, and packaging. Its corrosion-resistant features make it ideal for handling food products in moist and acidic conditions.

- Brewery and Beverage Industry: This chain is frequently utilized in breweries and beverage manufacturing facilities for bottling, labeling, and packaging tasks. Its robustness and resistance to chemical interactions render it suitable for managing various types of bottles and containers.

- Pharmaceutical Industry: The 662H Stainless Steel Pintle Chain is applied in the pharmaceutical industry for transporting, sorting, and packaging pharmaceuticals. Its hygienic attributes and resistance to chemical sterilization methods ensure compliance with stringent industry standards.

- Waste Water Treatment: This chain is commonly employed in wastewater treatment facilities to convey sludge, screens, and filters. Its corrosion resistance and ability to withstand harsh conditions make it suitable for continuous use in water treatment operations.

- Agricultural Sector: The 662H Stainless Steel Pintle Chain is used in agricultural machinery such as grain elevators, harvesters, and conveyors. Its strength and durability facilitate the efficient handling of crops and materials within the agricultural sector.

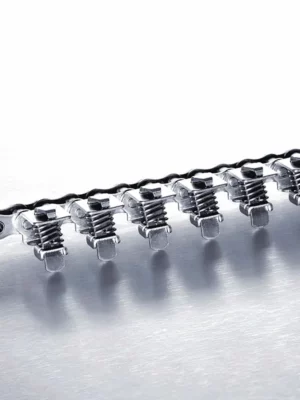

- Image:

Please note that the image provided is for illustrative purposes and may not represent the specific model of the 662H Stainless Steel Pintle Chain.

Maintenance Recommendations for 662H Stainless Steel Pintle Chain

To ensure optimal functionality and longevity of your 662H Stainless Steel Pintle Chain, adhering to proper maintenance practices is essential. Follow these guidelines for effective cleaning and lubrication of the chain:

- Cleaning: Regularly eliminate dirt, debris, and other contaminants from the chain. Utilize a brush or cloth to gently scrub the chain, ensuring all surfaces are thoroughly cleaned.

- Lubrication: Apply a suitable lubricant to the chain to diminish friction and prevent wear. Choose a lubricant specifically designed for stainless steel chains. Distribute the lubricant evenly along the entire length of the chain, ensuring it penetrates into the rollers and bushings.

- Tension: Regularly assess the chain's tension. Ensure it is correctly tensioned to prevent excessive wear and potential damage. Refer to the manufacturer's guidelines for the recommended tension settings.

- Inspection: Periodically examine the chain for any signs of damage, such as corrosion, bent or worn-out links. Immediately replace any damaged components to avert further issues.

By adhering to these maintenance recommendations, you can maintain your 662H Stainless Steel Pintle Chain in peak condition, thereby ensuring its performance and extending its lifespan.

Sprockets for Stainless Steel Chains

When selecting the appropriate sprockets for the 662H Stainless Steel Pintle Chain, several factors must be taken into account. First, it is essential to establish the desired speed ratio and torque needs for your specific application. This will help determine the number of teeth necessary on the sprocket.

Additionally, consider the pitch diameter and bore size of the sprocket. The pitch diameter should correspond with the chain's pitch, while the bore size should match the shaft diameter where the sprocket will be mounted. It is advisable to select sprockets crafted from high-quality stainless steel to ensure durability and resistance to corrosion.

Our company provides a diverse selection of sprockets to meet various requirements and specifications. Our extensive inventory includes an array of types, sizes, and configurations to accommodate a wide range of applications. Whether you need standard sprockets or customized options, we possess the expertise and capabilities to meet your needs.

Why Choose Our Stainless Steel Pintle Chains?

Our 662H Stainless Steel Pintle Chain is the premier choice for your chain requirements. At RP Techniek BV, we take pride in delivering a distinctive range of features that differentiate us from our competitors.

Primarily, our stainless steel pintle chains are renowned for their exceptional quality. We utilize only the finest stainless steel materials, ensuring durability and longevity. Whether your application demands a chain for heavy-duty use or corrosive conditions, our 662H Stainless Steel Pintle Chain is designed to endure the most challenging environments.

In addition to our superior quality, we are dedicated to providing outstanding service to our customers. Our knowledgeable team is always on hand to assist you with expert guidance. We recognize the importance of timely delivery and strive to meet your schedule requirements.

Furthermore, we are proud to serve as the Netherlands sales agent for Ever-power Group. This collaboration enables us to offer an extensive array of stainless steel roller chains, ensuring that we can address all your chain needs. You can rely on the superior quality of our chains, supported by the esteemed reputation of Ever-power Group.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...