Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Tip Clamp Type Gripper Chain Specifications

Type F 2 Tips Clamp

| HZPT Code | DIN/ISO | Material | Pitch | Inside Width | Roller Dia | Clamp Moving | Clamp Force | Tensile Strength | |||

| Base Chain | Clamp | Spring | P mm |

b1 Max mm |

d1 Max mm |

Vertical x mm |

Horizontal y mm |

Q-C N |

Q Min. kN |

||

| 08B1GC-F | 08B-1 | SS | SS | SS | 12.700 | 7.75 | 8.51 | 5 | 6 | 10 | 15.0 |

| 08B-1 | NP | SS | SS | 12.700 | 7.75 | 8.51 | 5 | 6 | 10 | 18.0 | |

Overview of Gripper Chains with Type F Tip Clamp

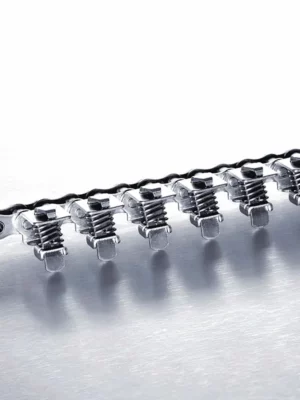

Ever-power Gripper Chains with Type F Tip Clamp are designed to provide maximum holding force and reliability for various wrapping applications in the food, electronics, and medical industries. The gripping force of the chains depends on the material being transported and the spring coils and diameter of the spring. These chains are available in both Nickel Plated and Stainless Steel, providing excellent corrosion resistance and outstanding wear-resistance.

The stainless springs used in the chains are made from Japan-imported material, ensuring consistent clamping force. Additionally, Pin and Bush are made of AISI 630HT, providing superior wear-resistance for the stainless steel base chain. The chains are supplied in pre-stretched and matched strands, guaranteeing trouble-free machine setup. A lube-free Nickel Plated chain version is also available upon request.

The Gripper Chains with Type F Tip Clamp are widely used for Form, Fill, and Vacuum Seal wrapping applications in the food industry for packaging ham, sausage, cheese, bread, fish, and more. They are also commonly used in the electronics industry for packaging wires, and in the medical industry for packaging injection syringes and pharmaceuticals.

Gripper Chains with Type F Tip Clamp Features

Ever-power's Gripper Chains with Type F Tip Clamp offer several unique features. The clamping force is highly dependent on the material being transported and the Spring coils & Dia. of Spring. The chain is designed with Base Chains available in both Nickel Plated and Stainless Steel, offering excellent corrosion resistance. The stainless steel springs are made of Japan-imported material, ensuring consistent clamping force. Additionally, the Pin & Bush of the stainless steel base chain are made of AISI 630HT, providing outstanding wear-resistance. The chain is supplied in pre-stretched and matched strands, guaranteeing trouble-free machine set-up. We also offer a lube-free Nickel Plated chain version upon request.

Gripper Chains with Type F Tip Clamp Applications

These gripper chains are widely used in various industries for form, fill and vacuum seal wrapping applications. In the food industry, they are used for packaging ham, sausage, cheese, bread, fish, and other products. In the electronics industry, they are used for packaging wires. In the medical industry, they are used for packaging injection syringes and pharmaceuticals, among other products.

Gripper Chain Applications

Gripper Chains with Type F Tip Clamp are versatile and find extensive use in various industries. Here are the key applications of these chains:

1. Food Industry: Gripper Chains are commonly employed in the packaging of a wide range of food products such as ham, sausage, cheese, bread, and fish. The reliable clamping force provided by the Type F Tip Clamp ensures secure and efficient packaging.

2. Electronics Industry: These chains are essential for packaging wires and cables in the electronics sector. The Type F Tip Clamp securely holds the wires in place, preventing tangling and damage during transportation and storage.

3. Medical Industry: Gripper Chains with Type F Tip Clamp are widely used in the medical industry for packaging items like injection syringes and pharmaceutical products. The precise clamping force of the chains ensures the safe and hygienic packaging of sensitive medical equipment.

[](https://netherlandsdrive.com/wp-content/uploads/2024/11/gripper-chain-2.jpg)

These applications highlight the versatility and reliability of Gripper Chains with Type F Tip Clamp in various industries, making them an essential component for form, fill, and vacuum seal wrapping applications.

How Does Grip Chains Work?

The Grip Chains in the Gripper Chains with Type F Tip Clamp are designed to provide a secure and reliable grip on objects. These chains are an essential component in various industrial applications, offering a versatile solution for gripping and handling tasks.

The grip chains function by utilizing the interlocking links to create a strong and durable structure. The links are carefully engineered to ensure optimal strength and flexibility, allowing them to withstand heavy loads and resist wear and tear.

When the gripper chains are in operation, the chain's links wrap around the object to be gripped, providing a tight and secure hold. The Type F Tip Clamp further enhances the gripping capability by exerting additional pressure on the object's surface.

The primary function of these grip chains is to provide a reliable gripping mechanism for various industrial processes. They are commonly used in material handling, assembly lines, and manufacturing operations where a secure grip is crucial for the efficient movement and manipulation of objects.

Maintenance of Gripper Chains

Gripper Chains with Type F Tip Clamp are an important component of industrial machinery, used for transporting materials with ease. However, these chains require regular maintenance to ensure their optimal performance. Here are some tips on how to maintain the chains:

- Regular cleaning: Gripper Chains should be cleaned regularly to remove any dust, dirt, or debris that may have accumulated on the chains. Use a damp cloth to wipe the chains, and ensure that the chains are completely dry before using them again.

- Lubrication: The chains should be lubricated with a suitable lubricant to reduce the friction between the chains, and to prevent them from wearing out quickly. It is recommended to lubricate the chains at least once a week.

- Inspection: The chains should be inspected regularly for any signs of wear and tear. Check for any signs of rust, cracks, or deformation in the chains. If any defects are found, the chains should be replaced immediately.

- Tensioning: The tension of the chains should be checked regularly to ensure that they are not loose or too tight. Loose chains may result in slippage, while tight chains may cause excessive wear and tear.

By following these maintenance tips, you can ensure that your Gripper Chains with Type F Tip Clamp remain in top condition, providing you with optimal performance. Here is an image to help you visualize the chains:

Sprockets for Gripper Chains

Gripper Chains with Type F Tip Clamp are an important component in many industrial applications. They rely on the cooperation of the chain and the sprocket to function effectively. The chain fits perfectly into the grooves of the sprocket teeth, allowing for smooth and precise movement.

It is crucial to have the correct sprocket to complement the Gripper Chains with Type F Tip Clamp. The sprocket must have the correct number of teeth and the appropriate pitch diameter to match the chain. This ensures that the chain and sprocket work together seamlessly, reducing wear and tear and maximizing efficiency.

At our company, we offer a range of sprockets that are compatible with Gripper Chains with Type F Tip Clamp. We understand the importance of having the right components to meet your needs, and we are committed to providing high-quality products that are reliable and durable.

Please see the image below for an example of our grip chain sprockets:

About Us

RP Techniek BV is the Dutch sales agent of Ever-power Group. We specialize in the production and promotion of Gripper Chains with Type F Tip Clamp.

Our Gripper Chains with Type F Tip Clamp are designed to provide efficient and reliable gripping solutions for various industries. These chains are engineered to withstand heavy loads and ensure precise positioning.

We take pride in our production capabilities and commitment to delivering high-quality products. Our chains are manufactured using top-grade materials and undergo rigorous quality control processes to meet industry standards.

Not only do we prioritize product quality, but we also offer competitive prices and excellent customer service. Our dedicated team is always ready to assist you with any inquiries or concerns.

We encourage you to explore our Gripper Chains with Type F Tip Clamp and get in touch with us for your purchase needs. Don't miss out on the opportunity to improve your operations with our reliable and durable chains.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...