Introduction

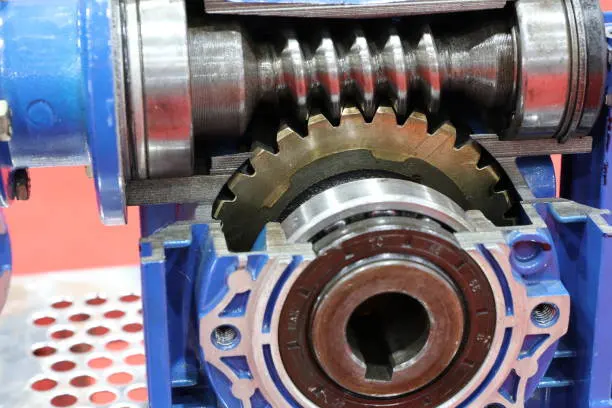

Quality control is of utmost importance in the manufacturing industry, especially when it comes to small worm gearboxes. Implementing a comprehensive quality control program ensures that the EPRV Series Small Worm Gearboxes meet the highest standards of performance, durability, and reliability. In this blog post, we will explore the key steps and considerations involved in implementing a quality control program for EPRV Series Small Worm Gearboxes.

1. Understanding the Importance of Quality Control

1.1 The Role of Quality Control in Gearbox Manufacturing

1.2 Benefits of Implementing a Quality Control Program

2. Establishing Quality Control Standards

2.1 Defining Key Performance Indicators (KPIs)

2.2 Setting Acceptance Criteria

3. Inspection and Testing Procedures

3.1 Incoming Material Inspection

3.2 In-Process Inspection

3.3 Final Product Testing

4. Documentation and Record Keeping

4.1 Maintaining Traceability

4.2 Documenting Inspection and Test Results

5. Continuous Improvement and Corrective Actions

5.1 Analyzing Non-Conformities

5.2 Implementing Corrective and Preventive Actions

6. Training and Skill Development

6.1 Ensuring Competency of Quality Control Personnel

6.2 Providing Ongoing Training and Development Opportunities

7. Supplier Quality Management

7.1 Evaluating and Selecting Reliable Suppliers

7.2 Establishing Quality Requirements for Suppliers

8. Conclusion

In conclusion, implementing a quality control program for EPRV Series Small Worm Gearboxes is crucial for ensuring the highest level of product performance and customer satisfaction. By following the steps outlined in this article, manufacturers can establish robust quality control processes that result in superior gearboxes. Remember, quality control is a continuous process that requires regular evaluation and improvement.

Electric motors for Sale

Electric motors play a crucial role in the operation of gearboxes, including the EPRV Series Small Worm Gearboxes. They provide the necessary power to drive the gearbox and enable the smooth and efficient functioning of various applications in industries such as equipment, food, car washing, packaging, transmission, automation, and solar energy. At our company, we understand the importance of a complementary relationship between gearbox and electric motors, which is why we offer a wide range of high-quality electric motors for sale.

About Us

RP Techniek BV, the Netherlands sales agent of Ever-power Group, is a comprehensive transmission equipment manufacturer specializing in research and development, manufacturing, and sales of speed reducers. With over 25 years of experience, we have established ourselves as a reputable and trusted provider of gearboxes, serving customers in Europe, America, Africa, Asia, and more.

Our commitment to excellence is reflected in our state-of-the-art production facilities, dedicated team of industry professionals and technicians, and innovative research and development capabilities. We adhere to strict production management methods to ensure the highest level of product quality, energy efficiency, and stability.

Our gearboxes find applications in a wide range of industries, including equipment, food, car washing, packaging, transmission, automation, and solar energy. We take pride in offering our customers top-notch products, competitive prices, and the highest level of service.

Q&A

Q1: What is the maximum torque capacity of EPRV Series Small Worm Gearboxes?

A1: The maximum torque capacity of EPRV Series Small Worm Gearboxes depends on the specific model and size. It is recommended to refer to the product specifications for accurate torque capacity information.

Q2: Are EPRV Series Small Worm Gearboxes suitable for high-speed applications?

A2: EPRV Series Small Worm Gearboxes are primarily designed for low-speed applications due to their inherent design characteristics. For high-speed applications, alternative gearbox options may be more suitable.

Q3: Can EPRV Series Small Worm Gearboxes be used in harsh environmental conditions?

A3: EPRV Series Small Worm Gearboxes are designed to withstand moderate environmental conditions. For harsh environments, additional protective measures or alternative gearbox options may be necessary.

Q4: What lubrication is recommended for EPRV Series Small Worm Gearboxes?

A4: It is recommended to use a high-quality, industrial-grade lubricant specifically formulated for worm gear applications. Consult the gearbox manufacturer for specific lubrication recommendations.

Q5: How can I ensure the longevity of EPRV Series Small Worm Gearboxes?

A5: Regular maintenance, including proper lubrication, inspection, and preventive measures, is essential for ensuring the longevity of EPRV Series Small Worm Gearboxes. Follow the manufacturer's guidelines for maintenance and consult with experienced technicians, if needed.

Edited by: Zqq.