Introduction

In this blog article, we will explore the advantages and applications of stainless worm gearboxes in extreme environments, with a specific focus on the city of Maastricht. Stainless worm gearboxes are essential components in various industries where durability and resistance to harsh conditions are paramount. Maastricht, a city known for its industrial prowess and demanding environmental conditions, requires reliable and high-performance gearboxes to ensure smooth operations in extreme environments.

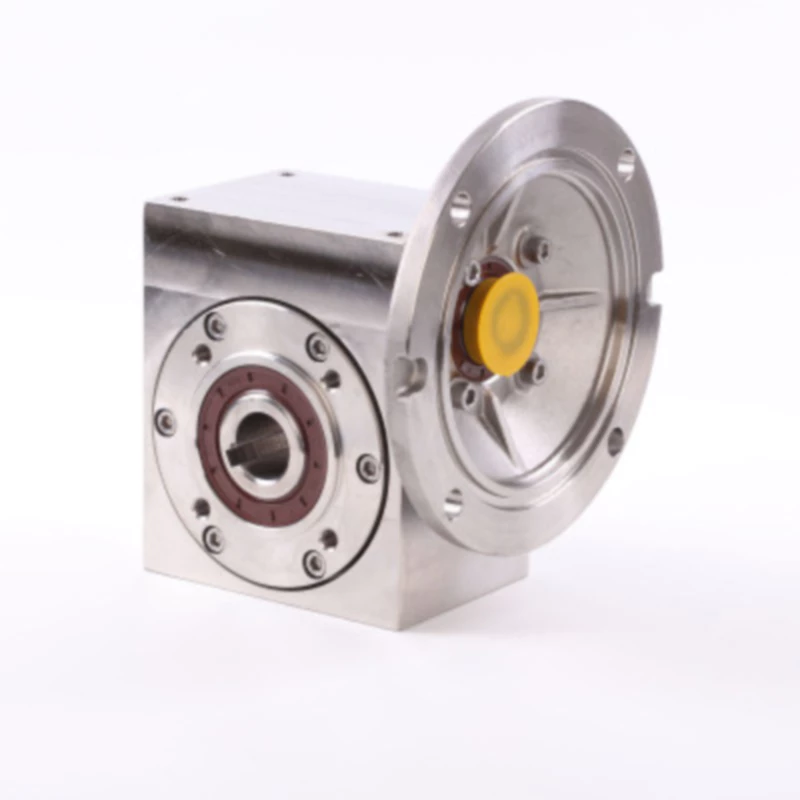

The Role of Stainless Worm Gearboxes

Stainless worm gearboxes play a crucial role in transmitting rotational motion and power between two perpendicular shafts. Their unique design, featuring a worm gear and a worm wheel, allows for high torque transmission and efficient power conversion. In extreme environments, such as those found in Maastricht, where moisture, corrosion, and temperature variations are common, stainless worm gearboxes demonstrate their exceptional performance and durability.

Advantages of Stainless Worm Gearboxes in Extreme Environments

1. Corrosion Resistance: Stainless steel construction provides excellent resistance to corrosion, making worm gearboxes suitable for applications where exposure to moisture and chemicals is common.

2. High Temperature Stability: Stainless worm gearboxes can operate in extreme temperature conditions without compromising performance or life expectancy, ensuring reliable operation in Maastricht's challenging environment.

3. Enhanced Durability: The robust construction of stainless worm gearboxes allows for prolonged service life, even in harsh industrial settings.

4. Lower Maintenance Requirements: With their exceptional resistance to wear and tear, stainless worm gearboxes reduce the need for frequent maintenance and repairs, resulting in cost savings for businesses in Maastricht.

Applications of Stainless Worm Gearboxes in Maastricht

The versatility and reliability of stainless worm gearboxes make them indispensable in various industries in Maastricht. Let's explore some key applications:

1. Industrial Automation

In the industrial automation sector, stainless worm gearboxes are utilized in conveyor systems, packaging machinery, and robotic applications. Their high torque capabilities and resistance to extreme conditions ensure smooth and efficient operations, even in demanding industrial environments.

2. Food and Beverage Industry

In the food and beverage industry, stainless worm gearboxes are crucial components in equipment such as mixers, conveyors, and bottling machines. Their corrosion resistance and compliance with strict hygiene standards make them ideal for ensuring the safety and quality of food and beverage production in Maastricht.

3. Renewable Energy

The renewable energy sector in Maastricht relies on stainless worm gearboxes for wind turbines and solar tracking systems. These gearboxes are designed to withstand harsh weather conditions and provide efficient power transmission, contributing to the city's sustainable energy goals.

Installation Process of Stainless Worm Gearboxes and Motors

Installing stainless worm gearboxes and motors requires careful attention to detail to ensure optimal performance and longevity. Here is a step-by-step guide to the installation process:

Step 1: Preparation

Before installation, ensure that all components are clean and free from debris. Inspect the gearbox and motor for any signs of damage.

Step 2: Mounting

Securely mount the gearbox and motor in the desired location, following the manufacturer's instructions. Ensure proper alignment between the input and output shafts.

Step 3: Electrical Connections

Connect the motor to a suitable power source, following electrical safety guidelines. Verify the correct voltage and wiring connections before energizing the system.

Step 4: Lubrication

Apply the recommended lubricant to the gearbox, ensuring all moving parts are adequately lubricated. Regularly check and replenish the lubricant as per the manufacturer's guidelines.

Step 5: Testing

After installation, perform a thorough functional test to ensure proper operation. Verify the motor speed, torque, and overall system performance.

Common Issues and Troubleshooting

| Problem | Solution |

|---|---|

| Excessive Noise | Check for loose or damaged gears. Inspect lubrication levels and replenish if necessary. If the issue persists, consult a professional technician. |

| Overheating | Ensure proper ventilation and cooling of the gearbox. Check for obstructions or debris blocking airflow. If the problem continues, consult a specialist to evaluate the system. |

| Poor Performance | Inspect for misalignment of shafts. Verify lubrication levels and use the recommended type of lubricant. If performance issues persist, seek professional assistance. |

| Leakage | Inspect seals and gaskets for damage or wear. Replace faulty components and ensure proper sealing. If leakage continues, consult a technician for further investigation. |

| Electrical Issues | Check wiring connections and ensure proper grounding. Verify voltage levels and troubleshoot any electrical faults. If necessary, consult an electrician. |

Stainless Steel Geared Motors for Sale

The synergy between stainless steel gearboxes and motors is crucial for efficient and reliable power transmission in various applications. In Maastricht, our company offers a wide range of stainless steel motors for sale, complementing our high-quality stainless worm gearboxes. These motors are specifically designed to work seamlessly with our gearboxes, ensuring optimal performance in extreme environments.

The importance of the relationship between gearboxes and motors cannot be overstated. Proper matching of these components ensures efficient power transmission, reduced energy consumption, and extended equipment life. Our stainless steel motors are engineered to withstand the demanding conditions of Maastricht, providing reliable and high-performance solutions for our customers.

About Us

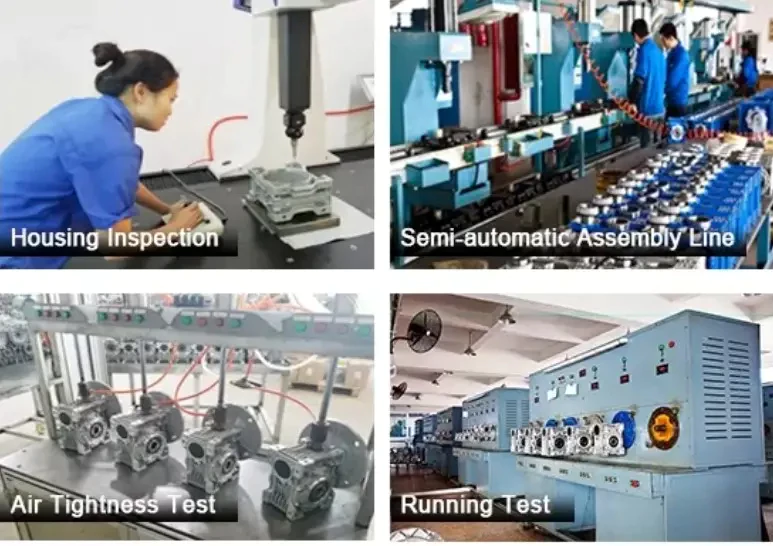

RP Techniek BV is the official sales agent for Ever-power Group in the Netherlands. We specialize in providing high-quality stainless worm gearboxes and have built a strong reputation for our manufacturing capabilities and commitment to customer satisfaction. Our clients span across Europe and the United States, and we are known for delivering superior service, top-notch product quality, and competitive pricing.

We encourage you to explore our range of products and get in touch with us for all your gearbox and motor needs. Our dedicated team is ready to assist you in finding the ideal solutions for your specific requirements. Trust RP Techniek BV for exceptional durability, reliability, and performance.

Q&A

Q: Can stainless worm gearboxes be used in underwater applications?

A: Yes, stainless worm gearboxes are suitable for underwater applications due to their corrosion resistance and ability to withstand moisture-rich environments.

Q: What maintenance is required for stainless worm gearboxes?

A: Stainless worm gearboxes require periodic lubrication, inspection for wear, and cleaning to ensure optimal performance and longevity.

Q: Are stainless worm gearboxes compatible with different motor types?

A: Yes, stainless worm gearboxes can be paired with various motor types, including electric motors, hydraulic motors, and pneumatic motors, depending on the specific application requirements.

Q: Can stainless worm gearboxes handle high torque loads?

A: Absolutely, stainless worm gearboxes are designed to handle high torque loads and provide reliable power transmission in demanding industrial applications.

Q: Are stainless worm gearboxes suitable for high-speed applications?

A: While stainless worm gearboxes can operate at moderate speeds, they are not recommended for high-speed applications due to their design and gear mesh characteristics.

Edited by: Zqq.