Introduction

Stainless steel worm gear reducers are essential components in various industrial applications, including Den Haag. These high-precision gear reducers play a crucial role in ensuring smooth and efficient power transmission in machinery and equipment. In this blog post, we will delve into the characteristics, benefits, and installation process of stainless steel worm gear reducers, shedding light on their importance in the manufacturing and productivity of Den Haag's industries.

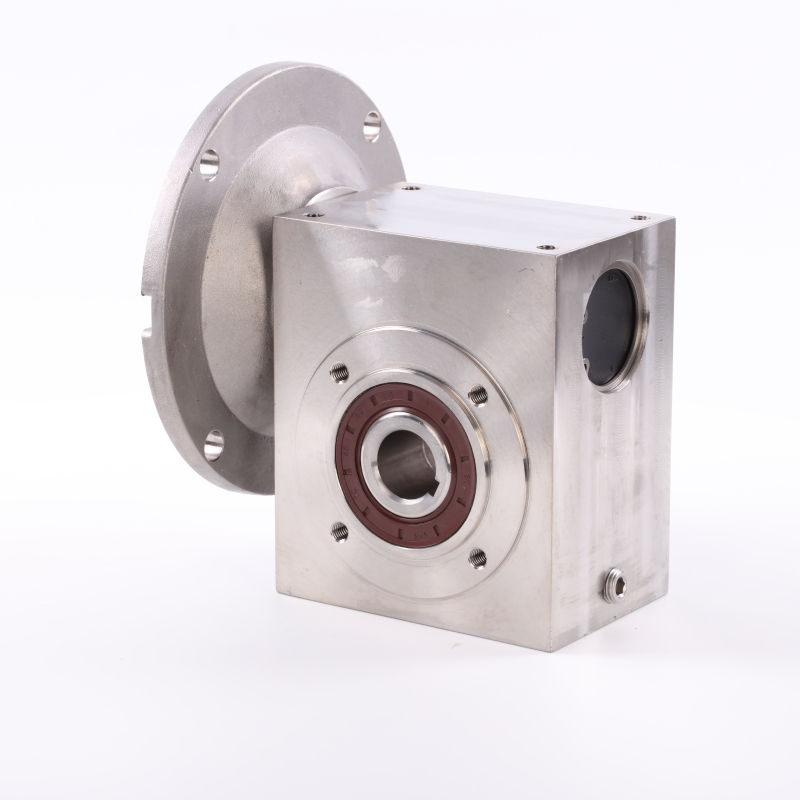

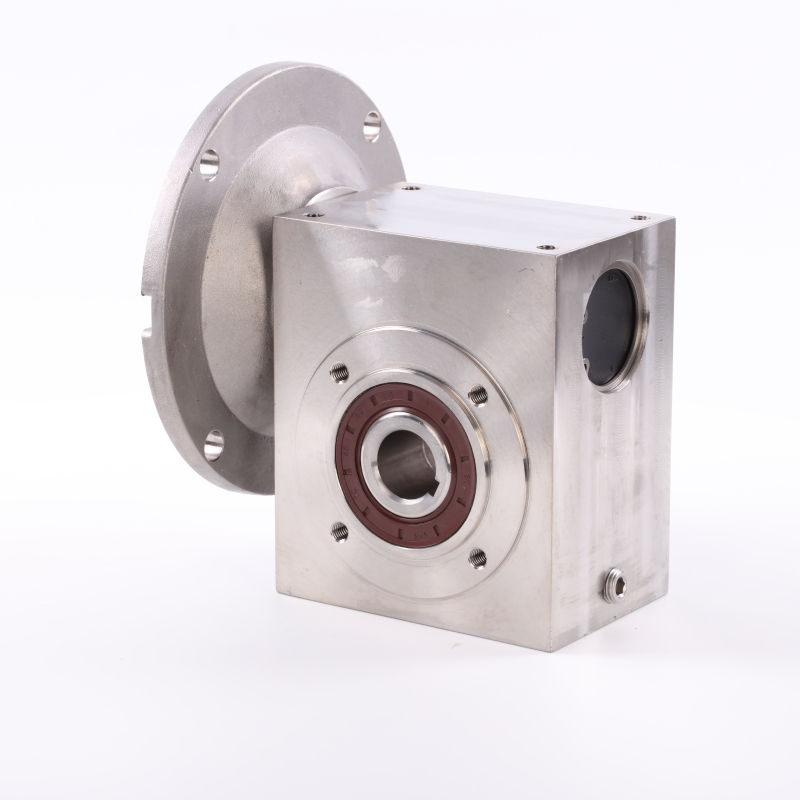

The Functionality of Stainless Steel Worm Gear Reducers

Stainless steel worm gear reducers offer precise and reliable speed reduction capabilities, making them indispensable in various applications. These gear reducers are designed to transmit power between non-intersecting shafts at right angles. By utilizing a worm and worm wheel mechanism, they provide torque multiplication and speed reduction, enabling smooth operation and enhanced control in industrial processes.

Key Features and Benefits

Stainless steel worm gear reducers boast several features that make them ideal for Den Haag's demanding industries. Firstly, their construction from high-grade stainless steel ensures exceptional durability, resistance to corrosion, and longevity, even in harsh environments. Secondly, the precision engineering of these gear reducers guarantees low noise levels, minimal vibration, and efficient power transmission.

Moreover, their compact design allows for easy integration into space-constrained applications. Additionally, stainless steel worm gear reducers offer high efficiency and precise positioning, resulting in improved overall system performance and reduced energy consumption. Their versatility and adaptability make them suitable for a wide range of industries, including food and beverage, pharmaceuticals, and automation.

Installation of Stainless Steel Worm Gear Reducers and Motors

The installation of stainless steel worm gear reducers and motors requires careful considerations to ensure optimal performance and longevity. Here are the key steps involved:

- Prepare the mounting surface and ensure it is clean and level.

- Attach the motor to the gear reducer using the specified coupling.

- Align the input and output shafts, ensuring they are in perfect alignment.

- Securely mount the gear reducer and motor assembly onto the prepared surface using appropriate fasteners.

- Connect the necessary electrical connections, following the provided wiring diagram.

- Perform a thorough check of all connections, ensuring they are secure and properly grounded.

- Test the system functionality and make any necessary adjustments.

- Regularly inspect and maintain the gear reducer and motor to ensure optimal performance and prevent any potential issues.

Troubleshooting Gearbox Issues

| Potential Problems | Solutions |

|---|---|

| Excessive noise or vibration | Check for misalignment, worn gears, or insufficient lubrication. Adjust or replace components as necessary. |

| Overheating | Ensure proper cooling and ventilation. Check for excessive loading or inadequate lubrication. |

| Loss of efficiency | Inspect for worn or damaged gears, bearings, or seals. Replace any faulty components. |

| Leakage of lubricant | Check for damaged seals or gaskets. Replace as needed and replenish lubricant. |

| Inconsistent or jerky operation | Inspect for worn or damaged gears, input/output shaft misalignment, or excessive loading. Address any issues accordingly. |

Stainless Steel Geared Motors for Sale

Stainless steel geared motors are an integral part of industrial applications, working in synergy with gear reducers to deliver optimal performance. The relationship between gearboxes and motors is symbiotic, with each component relying on the other's capabilities to achieve efficient power transmission and precise control. Our company offers a wide range of stainless steel motors for sale, ensuring compatibility and seamless integration with our stainless steel worm gear reducers.

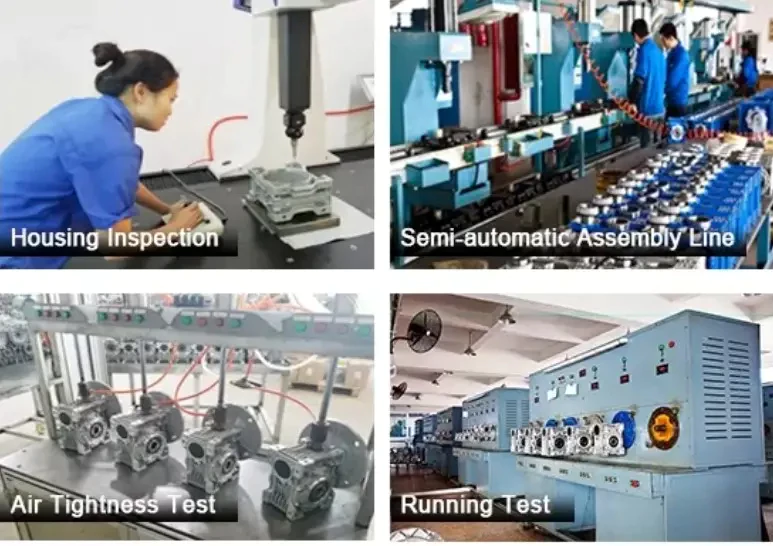

About Us

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. We pride ourselves on providing top-quality stainless steel worm gear reducers, leveraging our strong manufacturing capabilities and commitment to customer satisfaction. With a prestigious clientele across Europe and America, our company is renowned for delivering exceptional products, unparalleled service, and competitive pricing.

We encourage you to explore our range of stainless steel worm gear reducers and contact us for any inquiries or purchase requirements. We are dedicated to meeting your industrial needs with the highest product quality and utmost professionalism.

Q&A

Q: What industries can benefit from stainless steel worm gear reducers?

A: Stainless steel worm gear reducers find applications in various industries, including food and beverage, pharmaceuticals, packaging, and automation. They provide precise control, efficient power transmission, and resistance to corrosive environments, making them ideal for demanding industrial processes.

Q: How can I ensure proper alignment during the installation of gear reducers?

A: Proper alignment is crucial for optimal gear reducer performance. Use alignment tools, such as laser alignment systems, to ensure the input and output shafts are perfectly aligned. Regularly check and adjust alignment to prevent premature wear and reduce the risk of failures.

Q: Can stainless steel worm gear reducers handle high torque loads?

A: Yes, stainless steel worm gear reducers are designed to handle high torque loads. The worm and worm wheel mechanism provides torque multiplication, enabling them to transmit substantial power while maintaining precise control and efficient operation.

Q: How often should I lubricate stainless steel worm gear reducers?

A: Proper lubrication is vital for the smooth operation and longevity of stainless steel worm gear reducers. Follow the manufacturer's recommendations for lubrication intervals and use high-quality lubricants suitable for the specific operating conditions to ensure optimal performance and minimize wear.

Q: Are stainless steel worm gear reducers resistant to corrosion?

A: Yes, stainless steel worm gear reducers are highly resistant to corrosion. Their construction from high-grade stainless steel ensures exceptional durability and longevity, even in harsh environments where exposure to moisture, chemicals, and other corrosive elements is prevalent.

Edited by: Zqq.