In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

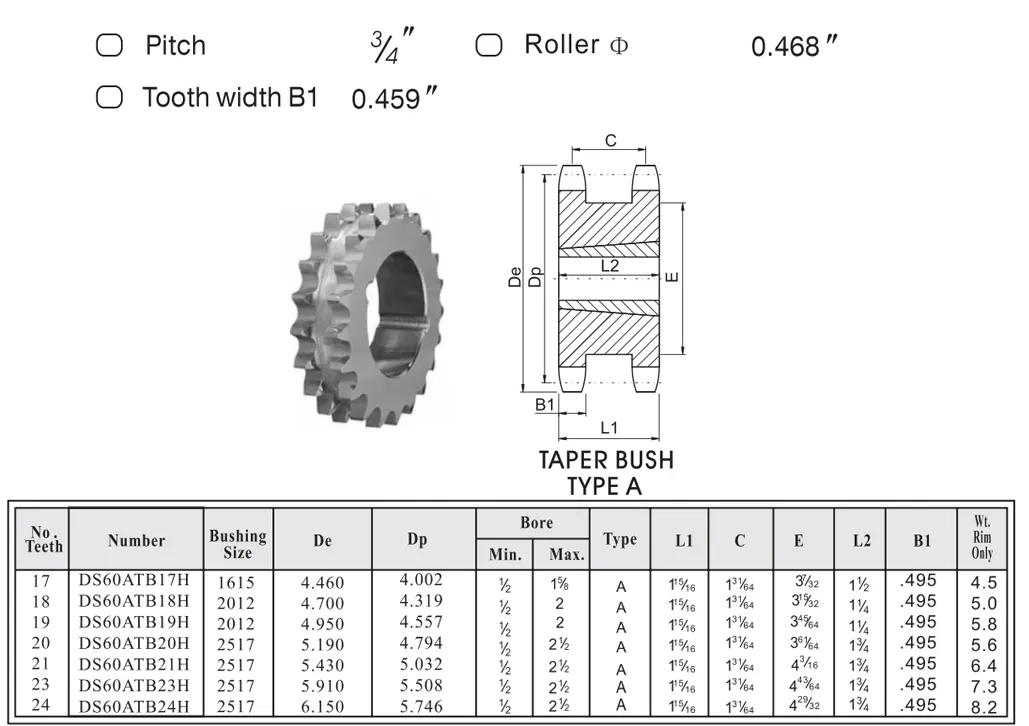

60 Taper Bushed Type Double Single Sprocket

The 60 Taper Bushed Type Double Single Sprocket is engineered for high performance and durability in various applications. Designed to accommodate standard taper bushings, it allows for easy installation and replacement. This sprocket ensures smooth power transmission and is ideal for heavy-duty machinery, making it a reliable choice for your operational needs.

Specifications of 60 Taper Bushed Type Double Single Sprocket

Design Features of 60 Taper Bushed Type Double Single Sprocket

The 60 Taper Bushed Type Double Single Sprocket is engineered with a distinctive design that facilitates the simultaneous operation of two single-row chains. This configuration not only improves flexibility but also enhances efficiency in power transmission. By enabling two chains to operate together, the sprocket effectively distributes load, thereby minimizing stress on each chain. This results in reduced wear and tear, leading to an extended service life and superior performance, making it suitable for a wide range of demanding applications.

Surface Treatment of 60 Taper Bushed Type Double Single Sprocket

The surface treatment process for the 60 Taper Bushed Type Double Single Sprocket includes several critical steps designed to enhance durability and wear resistance. Initially, the sprocket is meticulously cleaned to eliminate all contaminants. Following this, a protective corrosion-resistant coating is applied to safeguard it against various environmental factors. Afterward, a heat treatment elevates the hardness of the sprocket, ensuring it can withstand heavy loads. Finally, a finishing touch is given to produce a smooth surface that minimizes friction during operation. This comprehensive treatment process ensures that the sprocket retains its performance capabilities and structural integrity over time, making it ideal for rigorous applications.

Application Areas of 60 Taper Bushed Type Double Single Sprocket

The 60 Taper Bushed Type Double Single Sprocket is crafted to tackle a wide range of challenges across various industries, ensuring reliable power transmission and efficient performance. Its robust design allows it to excel in numerous applications, including:

- Conveyor systems utilized in manufacturing settings

- Agricultural machinery designed for enhanced durability

- Automated assembly lines that require precise synchronization

- Mining equipment specifically engineered for heavy-duty operations

- Textile machinery aimed at boosting production efficiency

Optimized Sprocket Spacing Design

The 60 Taper Bushed Type Double Single Sprocket boasts an innovative sprocket spacing design that guarantees optimal chain clearance while preventing any potential interference. This design is the result of meticulous calculations to determine the precise distance between sprockets, allowing for smooth chain operation and significantly reducing wear. By ensuring the ideal spacing, the sprocket minimizes the risk of chain derailment, thus enhancing the overall efficiency of the system. The end result is a reliable and durable performance that meets the rigorous demands of diverse applications.

Double Single Sprockets Supplier

RP Techniek BV serves as the sales agent for Ever-power Group, establishing itself as one of the leading sprocket suppliers in the Netherlands. Our company focuses on delivering high-quality sprockets, including the 60 Taper Bushed Type Double Single Sprocket, which is designed to achieve optimal performance and longevity in various applications.

Our sprockets feature a solid construction that ensures they can endure heavy loads while providing dependable operation. They are well-suited for both industrial and agricultural settings, effectively offering excellent torque transmission capabilities.

At RP Techniek BV, we are committed to providing outstanding service, which includes expert advice, prompt shipping, and tailored solutions that cater to your specific requirements.

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...