In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The hoist sprocket is a key component used in lifting machinery, whose main function is to lift and lower the load by cooperating with the chain. Lifting sprockets are usually made of high-strength ductile iron with needle roller bearings inside to provide high strength and good carrying capacity.

Hoist Chain Sprocket Structure and Function

Core structure

Lifting hoist sprockets are usually composed of the wheel body, chain grooves (tooth grooves) and shaft holes. The shape and size of the chain socket need to be precisely matched with the links of the chain to ensure smooth meshing of the chain during the transmission process and reduce impact and wear.

Power transmission mechanism

The rotation of the sprocket drives the chain to move, and the chain links of the chain are inserted into the chain socket to achieve the transmission of power. The tooth profile design of the sprocket should ensure that there is no interference when the chain is meshed in and out, avoiding tooth skipping or chain jamming.

Braking and limit function

Some hoisting sprockets are integrated with load-limiting devices or thrust washers to prevent the chain from overloading or the sprocket from reversing. For instance, the load-limiting hand sprocket avoids unstable braking caused by brake pad wear through the load-limiting device, while the thrust washer can prevent the sprocket and nut from locking when the chain drops to the limit position.

Application Scenarios of Hoist Sprockets

- Hand chain hoist

The hoist sprocket is the core component of the hand chain hoist. Through the rotation of the sprocket, it drives the chain to move, achieving the lifting and lowering of heavy objects. Manual chain hoists are widely used in construction, warehousing, logistics and other fields.

|

|

|

|

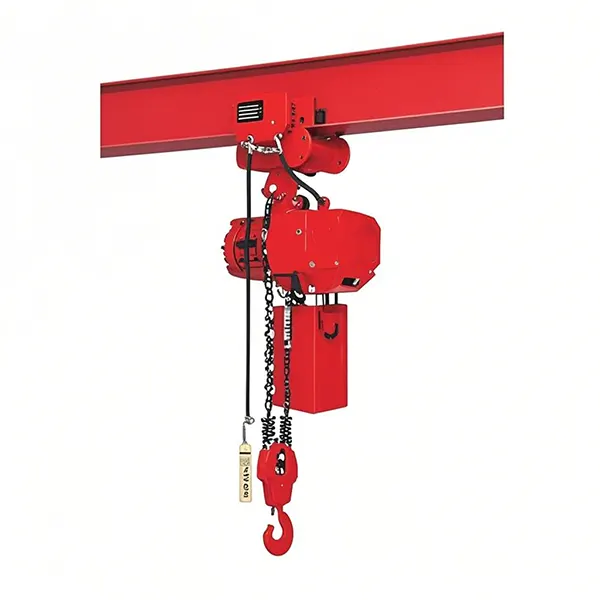

- Electric hoists and cranes

In electric hoists and cranes, the chain hoist sprocket works in conjunction with the chain to achieve precise hoisting and positioning of heavy objects. The design of the sprocket needs to meet the requirements of high load and high efficiency.

|

|

|

|

- Special working condition equipment

In high-temperature, humid or oily environments, the hoist sprocket needs to have good corrosion resistance and wear resistance to ensure the reliable operation of the equipment.

Materials and Manufacturing Processes of Hoist Chain Sprockets

- High-strength material

Sprockets for hoists are usually made of high-strength ductile iron or alloy steel to ensure reliability and durability under heavy load and high-stress conditions. For instance, ductile iron has the advantages of high wear resistance, good lubricity and high casting efficiency. - Manufacturing process

The chain socket needs to be cast in one go to ensure dimensional accuracy and surface quality. If the casting or spheroidization is not up to standard, it may lead to a decrease in the toughness of the sprocket and even cause it to break.

Hoist Sprocket Design

- Tooth profile design

The tooth profile of the hoist sprocket needs to be precisely matched with the links of the chain to ensure smooth operation of the chain during meshing, reducing impact and wear. Unreasonable tooth profile design may lead to tooth skipping or chain breakage. - Strength and wear resistance

The chain hoist sprocket needs to bear the weight of the chain and the heavy object. When designing, the strength of the gear teeth needs to be calculated to ensure that fatigue fracture does not occur during long-term use. Meanwhile, the surface of the sprocket needs to be hardened to enhance its wear resistance. - Buffering and shock absorption performance

The sprocket for hoist needs to have certain buffering and shock absorption performance to reduce the vibration and noise of the chain during the transmission process and extend the service life of the equipment.

Common Problems with Hoist Sprockets

| Problem | Description | Solution |

|---|---|---|

| Excessive Wear or Tooth Deformation | Over time, sprocket teeth can become worn, chipped, or deformed due to load stress or poor lubrication. | Regularly inspect sprockets for signs of wear. Replace worn sprockets promptly to prevent additional damage to the chain and reduced lifting efficiency. Ensure proper lubrication to minimize friction. |

| Improper Chain Engagement | Misalignment between the sprocket and the chain can cause the chain to skip or derail, leading to uneven wear or failure. | Check alignment regularly and realign components as needed. Ensure that the chain matches the sprocket pitch and size. |

| Corrosion and Rust | Exposure to moisture or corrosive environments can lead to rust and pitting on sprocket surfaces. | Use corrosion-resistant materials or coatings. Implement routine cleaning and apply protective lubricants to minimize rust. |

| Cracks or Structural Damage | Heavy loads or impacts can cause cracks in the sprocket body or teeth. | Perform regular visual and non-destructive inspections. Replace any sprockets showing signs of cracking to avoid catastrophic failure. |

| Improper Installation | Incorrect installation may lead to poor performance, accelerated wear, or unsafe operation. | Follow manufacturer guidelines during installation and maintenance. Ensure all fasteners are properly torqued and components are securely mounted. |

Where to Buy Hoist Sprockets? Contact Us for Premium Solutions!

Looking for reliable hoist sprocket suppliers or high-quality hoist sprockets for sale? Our company specializes in manufacturing and exporting custom hoist sprockets and OEM hoist sprockets tailored to global clients’ needs. Whether you require standard models for immediate replacement or bespoke designs for specialized machinery, our team ensures precision engineering, durable materials, and competitive pricing.

Ready to Upgrade Your Equipment?

Request a Quote Today for bulk orders, OEM partnerships, or customized hoist sprockets.

Contact Us via email/phone/chat—our team is eager to assist!

Don’t compromise on quality. Partner with a trusted hoist sprocket manufacturer like us and elevate your machinery’s performance!

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...