In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

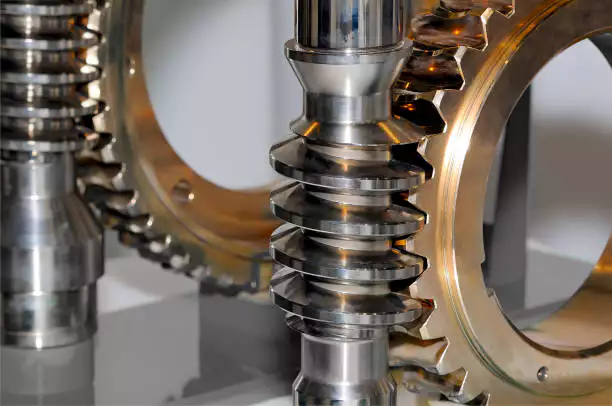

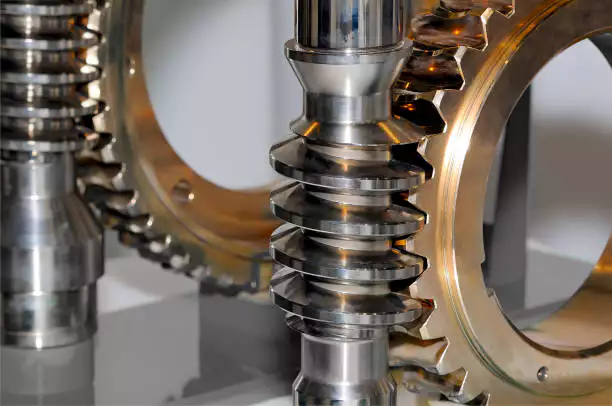

Worm Gear for Presses

The worm gear for presses is a specialized mechanical component designed to provide precise motion control in various pressing applications. Typically utilized in press machines, this worm gear offers high torque, making it ideal for heavy-duty operations. In mechanical presses, the worm gear ensures smooth and reliable performance, enhancing efficiency. Common press worm gear applications include metal forming and assembly processes in the manufacturing industry, where the durability and reliability of a worm gear for industrial presses are crucial for optimal results.

Specifications of Worm Gear for Presses

| Specification | Details |

|---|---|

| Gear Ratio | 25:1 |

| Material | Alloy Steel |

| Load Capacity | 2000 lbs |

| Efficiency | 85% |

| Output Shaft Diameter | 1 inch |

| Operating Temperature Range | -20°C to 100°C |

Why Worm Gears are Suitable for Worm Gear for Presses Applications

- Worm gears for presses provide high torque, making them ideal for heavy-duty applications in press machines.

- These gears offer excellent load distribution, ensuring reliability in mechanical presses.

- Worm gear in press machines allows for precise control of speed and movement, crucial for accurate press operations.

- Press worm gear applications benefit from their compact design, saving space in industrial settings.

- High-torque worm gear for presses enhances performance and efficiency in industrial presses.

How Worm Gears Work in Presses

Worm gears play a crucial role in press machines, providing reliable power transmission and high torque. The worm gear for presses is designed to convert rotational motion into linear force, which is essential for various press applications. In mechanical presses, the worm gear's unique design allows for smooth operation and precise control, making it ideal for high-torque requirements. The worm gear in press machines ensures efficient energy transfer while minimizing backlash, enhancing overall performance. Additionally, the press worm gear applications extend to industrial presses, where durability and strength are vital. By utilizing a high-torque worm gear for presses, manufacturers can achieve greater efficiency and productivity in their operations.

Manufacturing Process of Worm Gear for Presses

- Material Selection: The manufacturing of worm gears for presses begins with the careful selection of high-quality materials. Typically, steel or specialized alloys are chosen for their durability and strength. This is crucial as the worm gear in press machines must withstand high loads and torque. The chosen material affects the gear's performance in press worm gear applications, ensuring longevity and reliability in industrial settings.

- Precision Machining: After material selection, the next step involves precision machining. This process includes cutting, shaping, and grinding the raw material to create the worm gear's specific dimensions and tolerances. Advanced CNC (Computer Numerical Control) machines are often employed to achieve the required accuracy. This precision is vital for the worm gear for industrial presses, as any inaccuracies can lead to inefficiencies or failures in mechanical presses.

- Heat Treatment: Once the worm gear has been machined, it undergoes heat treatment to enhance its mechanical properties. This process involves heating the gear to a specific temperature and then cooling it at controlled rates. Heat treatment increases the hardness and strength of the worm gear, making it suitable for high-torque applications in press machines. The improved material properties ensure that the worm gear can endure the rigorous demands of mechanical presses.

- Surface Finishing: The final stage of the manufacturing process is surface finishing. This step includes processes such as polishing, coating, or plating to improve the worm gear's surface quality. A smooth surface reduces friction, enhances efficiency, and prevents wear in worm gear in press machines. Additionally, surface treatments can provide corrosion resistance, extending the lifespan of the gear in various press worm gear applications.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands.

We specialize in worm gears for presses and offer a range of products that stand out due to their exceptional quality and performance. Our offerings include:

- High-quality worm gears designed to meet rigorous industrial standards.

- Robust construction ensuring durability and long service life.

- Customizable solutions tailored to specific application requirements.

- Comprehensive after-sales support and expert guidance from our dedicated team.

With our strong market presence and commitment to excellence, we strive to provide not only top-notch products but also unparalleled service to our clients.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...