In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

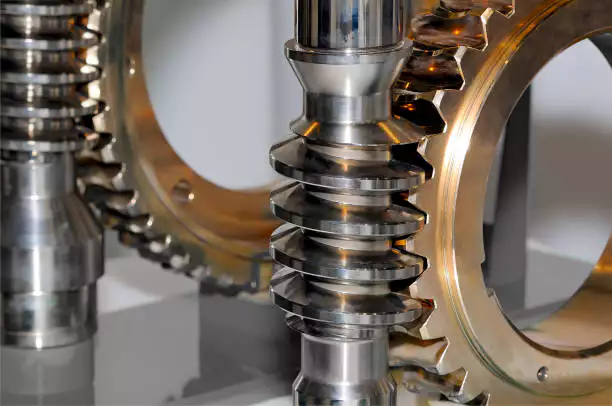

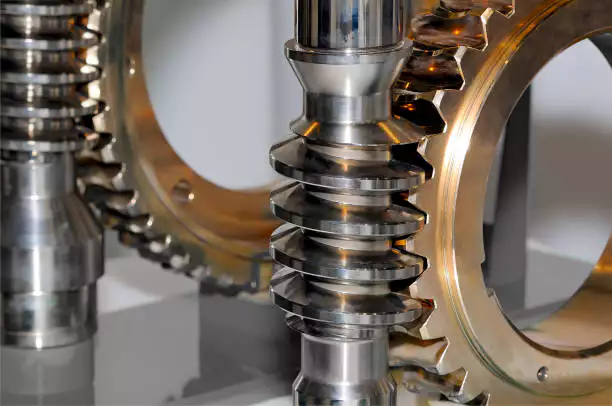

Worm Gear for Heavy-Duty Equipment

The worm gear for heavy-duty equipment is a specialized mechanical component designed to provide high torque and efficient power transmission in demanding environments. Commonly found in heavy machinery, this durable worm gear for heavy-duty use ensures reliable operation under extreme conditions. Its unique design allows for smooth movement and precise control, making it ideal for heavy-duty worm gear applications. In industrial equipment, the worm gear in robust machinery facilitates the effective handling of loads, enhancing performance and longevity, essential for any industrial setting.

Specifications of Worm Gear for Heavy-Duty Equipment

| Specification | Details |

|---|---|

| Gear Ratio | 20:1 |

| Material | Alloy Steel |

| Load Capacity | 5000 lbs |

| Efficiency | 90% |

| Temperature Range | -20 to 100 °C |

| Mounting Type | Flange Mount |

Why Worm Gears are Suitable for Heavy-Duty Equipment

Worm gears are ideal for heavy-duty equipment due to several key factors:

- High Torque Transmission: The design of a worm gear allows for efficient torque transfer, making it perfect for worm gear for heavy-duty equipment.

- Compact Size: Worm gear in heavy machinery saves space while providing robust performance.

- Durability: A durable worm gear for heavy-duty use ensures long-lasting operation even under extreme conditions.

- Low Backlash: This is crucial for heavy-duty worm gear applications, allowing for precise movement in worm gear for industrial equipment.

- Versatility: Used in various worm gear in robust machinery, they adapt well to different operational needs.

How Worm Gears Work in Heavy-Duty Equipment

Worm gears play a crucial role in heavy-duty equipment by providing high torque and reducing speed. They consist of a worm (a screw-like component) and a worm wheel, allowing for smooth operation in heavy machinery. In heavy-duty worm gear applications, these gears are designed to handle substantial loads, making them essential in industrial equipment. The durable worm gear for heavy-duty use ensures longevity and reliability in robust machinery, enabling efficient power transmission. By utilizing a worm gear in heavy machinery, operators benefit from the ability to achieve precise control and high mechanical advantage, which is vital in various industrial settings.

Manufacturing Process of Worm Gear for Heavy-Duty Equipment

The manufacturing process of a worm gear for heavy-duty equipment involves several critical steps to ensure durability and efficiency. Here are the detailed steps explaining the process and manufacturing techniques:

- Material Selection: The first step in creating a durable worm gear for heavy-duty use is selecting the right materials. High-strength steel alloys are commonly used for their ability to withstand the significant loads and stresses typical in heavy machinery. The choice of material affects the overall performance and longevity of the worm gear in heavy machinery, making it essential to select materials that offer both strength and resilience.

- Precision Machining: Once materials are selected, the next phase is precision machining. This involves using computer numerical control (CNC) machines to cut and shape the worm gear accurately. CNC machining ensures that the gear teeth are correctly formed, which is vital for the efficiency of the worm gear in robust machinery. The precision achieved in this stage directly contributes to the effectiveness of heavy-duty worm gear applications.

- Heat Treatment: After machining, the worm gear undergoes heat treatment to enhance its mechanical properties. This process involves heating the gear to a specific temperature and then cooling it rapidly. Heat treatment increases the hardness and wear resistance of the worm gear for industrial equipment, ensuring it can operate under high loads without deforming or failing.

- Surface Finishing: The final step involves surface finishing, which is crucial for reducing friction and wear during operation. Techniques such as grinding and polishing are employed to achieve a smooth surface on the worm gear. This finishing process helps improve the performance of the worm gear for heavy-duty equipment, ensuring it operates efficiently in demanding environments.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands.

Our product offerings include:

- High-Quality Worm Gears: We provide worm gears designed for heavy-duty equipment, ensuring durability and reliability under extreme conditions.

- Exceptional Craftsmanship: Our products are manufactured with precision, meeting the highest quality standards to ensure optimal performance.

- Strong Industry Presence: With years of experience in the market, we have established ourselves as a trusted supplier in the industry.

- Comprehensive Customer Service: We are committed to providing superior customer support, helping clients choose the right solutions for their needs.

Our dedication to quality and service sets us apart from competitors.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...