Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Types and Sizes of 80 Weld on Sprockets and Hubs

| No.Teeth | 80 |

| 1" Pitch | |

| 9 | 80W9 |

| 10 | 80W10 |

| 11 | 80W11 |

| 12 | 80X12 |

| 13 | 80X13 |

| 14 | 80X14 |

| 15 | 80X15 |

| 16 | 80X16 |

| 17 | 80X17 |

| 18 | 80X18 |

| 19 | 80X19 |

| 20 | 80X20 |

| 21 | 80X21 |

| 22 | 80X22 |

| 23 | 80X23 |

| 24 | 80X24 |

| 25 | 80X25 |

| 26 | 80X26 |

| 27 | 80X27 |

| 28 | 80X28 |

| 29 | 80X29 |

| 30 | 80X30 |

| 32 | 80X32 |

| 33 | 80X33 |

| 34 | 80X34 |

| 35 | 80X35 |

| 36 | 80X36 |

| 40 | 80X40 |

| 45 | 80X45 |

| 48 | 80X48 |

| 54 | 80X54 |

| 60 | 80X60 |

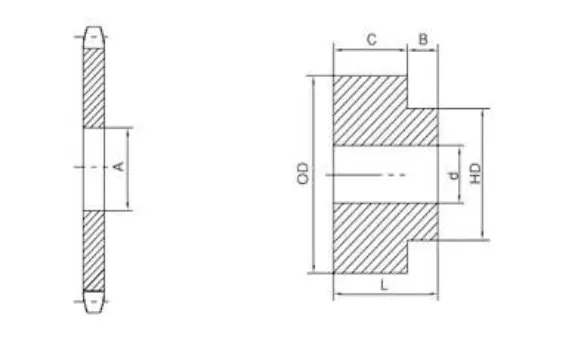

| Hub No. | Chain No. | d Min. |

d Max. |

OD | HD | L | B | C | App.WL. (Lbs.) | A |

| V | 35-60 | 0.5 | 0.875 | 1.438 | 1.125 | 1.188 | 0.438 | 0.75 | 0.32 | 1-1/8 |

| W | 35-80 | 0.5 | 1.25 | 1.813 | 1.625 | 1.438 | 0.438 | 1 | 0.64 | 1-5/8 |

| X | 40-100 | 0.5 | 1.5 | 2.5 | 2 | 1.438 | 0.438 | 1 | 1.42 | 2 |

| XX | 40-100 | 1 | 1.625 | 3 | 2 | 1.5 | 0.438 | 1.063 | 2.2 | 2 |

| Y | 100 | 1 | 2 | 3.75 | 2.75 | 1.875 | 0.688 | 1.188 | 3.92 | 2-3/4 |

Applications of 80 Weld on Sprockets and Hubs

The 80 Weld on Sprockets and Hubs are widely used in various industries, including manufacturing, agriculture, and automotive. These components are ideal for heavy-duty applications such as conveyor systems and agricultural machinery, ensuring efficient power transmission. Typical use cases include drive systems in packaging machinery and material handling equipment, making them suitable for businesses seeking durability and reliability.

Installation of 80 Weld on Sprockets and Hubs

To install the 80 Weld on Sprockets and Hubs, follow these steps:

- Clean the surfaces to ensure proper adhesion.

- Align the sprocket with the hub and mark the welding points.

- Preheat the components if necessary for better weld quality.

- Weld the sprocket to the hub, ensuring even heat distribution.

- Allow the weld to cool before testing for stability.

How to Choose the Right Weld on Sprockets and Hubs

When selecting the appropriate weld on sprockets and hubs, consider the following steps:

- Identify Application Requirements: Determine the specific needs of your machinery or project.

- Check Compatibility: Ensure the sprockets and hubs match the existing components.

- Assess Material Quality: Choose high-quality materials for durability and performance.

- Evaluate Size and Design: Select the correct size and design to fit your operational demands.

Weld on Sprockets and Hubs for Sale in Netherlands

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, and we are one of the top sprocket suppliers in the country. Our extensive range of products includes over 80 types of weld on sprockets and hubs designed to meet diverse industrial needs. Each sprocket is manufactured with precision to ensure optimal performance and durability, making them ideal for various applications in machinery and equipment.

In addition to our high-quality products, we pride ourselves on providing exceptional customer service. Our team is dedicated to helping clients find the right solutions for their specific requirements, ensuring timely delivery and support throughout the purchasing process.

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...