Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

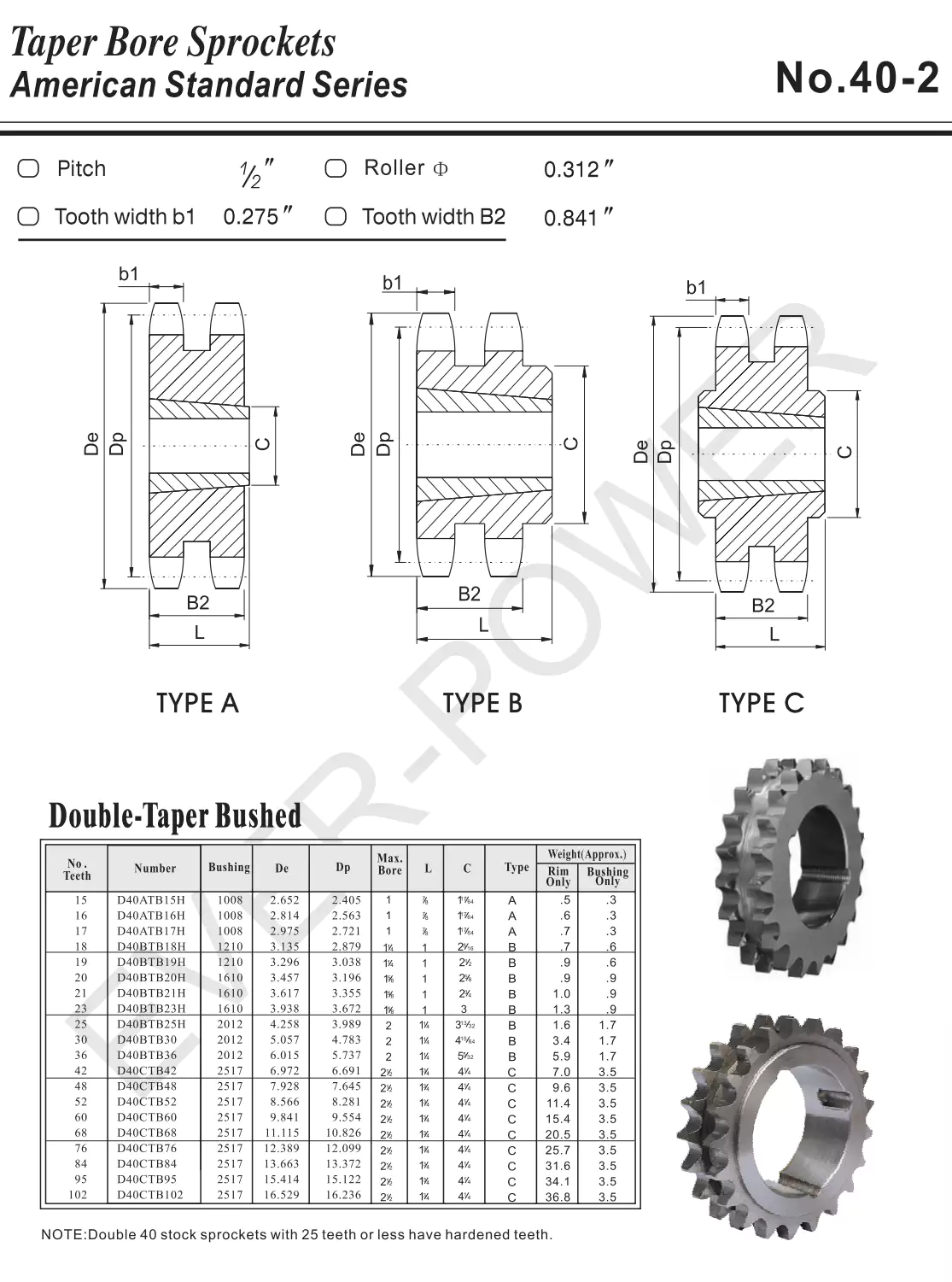

#40-2 1/2″ Taper Bore Sprocket

The #40-2 1/2″ Taper Bore Sprocket is designed for robust performance in various mechanical applications. Its tapered bore allows for easy installation and secure fitment on shafts, minimizing wear and improving efficiency. Made from high-quality materials, this sprocket ensures durability and reliability, making it an ideal choice for your power transmission needs.

#40-2 1/2" Taper Bore Sprocket Specifications

#40-2 1/2" Taper Bore Sprocket is specifically engineered to function alongside a taper lock bushing. This specialized sprocket plays an essential role in power transmission systems by enabling efficient power transfer between rotating shafts. It securely fits onto a machine's shaft, allowing a chain to effectively run over it, thus ensuring smooth and reliable power transmission throughout the system.

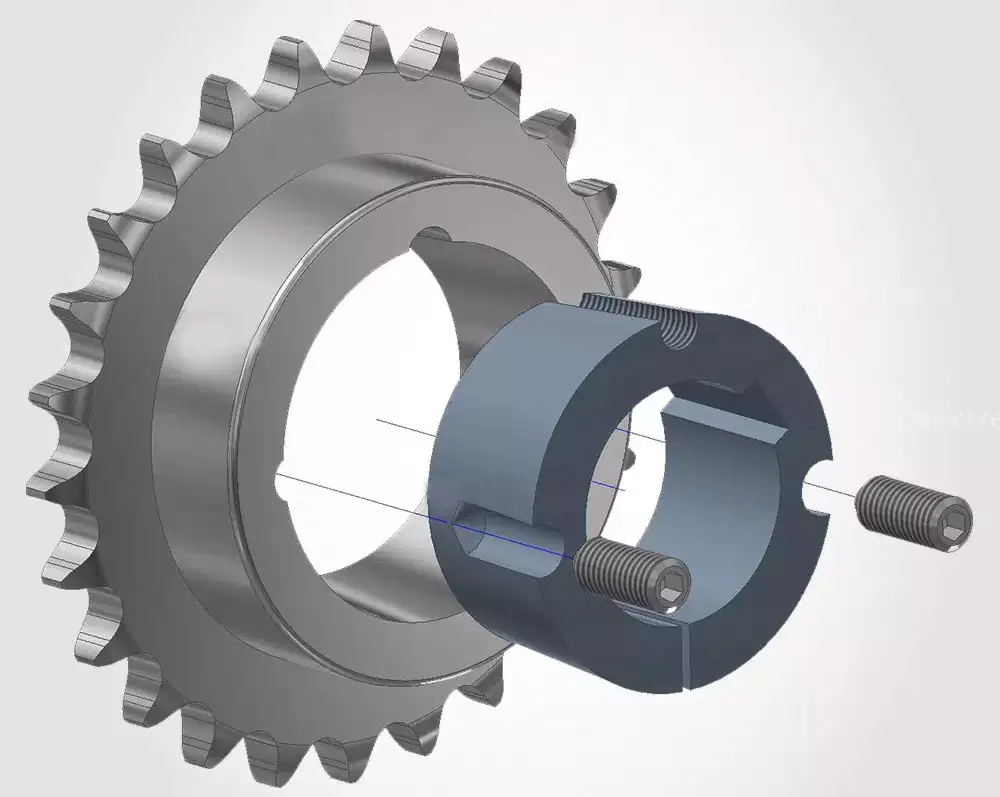

Taper Bore Sprocket: Definition and Basic Structure

A taper bore sprocket is uniquely created for mounting on a shaft utilizing a taper lock bushing. Its design consists of a robust hub, a sequence of precisely crafted teeth, and a bore that perfectly accommodates the shaft's dimensions. The taper lock bushing is securely attached to the shaft, while the sprocket itself is mounted onto this bushing, ensuring stability and functionality.

Features and Functions of Taper Bore Sprocket

The taper bore sprocket is characterized by a variety of features and functions that enhance its significance in power transmission systems:

- Easy to install: Its design allows for quick and uncomplicated installation, making it a popular choice for many machines and applications.

- High precision positioning: It enables accurate positioning, which is vital for machinery that operates at high precision levels.

- Widely applicable: This sprocket can be utilized in a broad spectrum of machines and varied applications.

- Reliability: Engineered for dependability, it is ideal for machines that demand prolonged periods of operation without failure.

- Low maintenance costs: Designed to require minimal maintenance, it allows for infrequent servicing, which reduces operational disruptions.

The primary advantage of the taper bore sprocket lies in its ease of installation and removal, making it the preferred choice for machines that require frequent maintenance or repairs.

Installation and Removal of Taper Bore Sprocket

The procedure for installing and removing a taper bore sprocket is straightforward and can be accomplished with a few simple steps:

- Prepare tools and materials: Assemble all necessary tools and materials such as the taper lock bushing, a torque wrench, and a socket set to ensure a smooth installation process.

- Clean shaft and sprocket surface: Make sure the shaft and the bore surface of the sprocket are thoroughly clean and free from any dirt or debris to facilitate a successful installation.

- Place taper lock bushing: Carefully slide the taper lock bushing onto the shaft and secure it by tightening the set screws against the shaft to ensure stability.

- Install sprocket: Position the sprocket over the taper lock bushing, ensuring that the keyway in both components is properly aligned for effective power transmission.

- Tighten locking nut: Utilize a torque wrench to tighten the locking nut at the end of the bushing, adhering to the specified torque value for optimal performance.

Manufacturing Process of Taper Bore Sprocket

The manufacturing process for a taper bore sprocket involves several key steps:

- Prepare raw materials: Choose the suitable type of steel or other materials that are necessary for the production of the sprocket.

- Cut material: Cut the selected material to the appropriate size and shape using a saw or a cutting tool to prepare it for the next step.

- Forge or cast: Forge or cast the material into the preliminary shape of the sprocket, forming the basic structure.

- Machine: Machine the sprocket to achieve its final dimensions, including precise bores and accurately shaped teeth.

- Roll teeth: Utilize a specialized rolling machine to roll the teeth of the sprocket into place, ensuring their effectiveness in power transmission.

- Heat treat: Subject the sprocket to heat treatment to enhance its strength and durability, making it more resilient in operation.

- Surface treatment: Apply a protective surface treatment, such as plating or painting, to shield the sprocket from corrosion and wear over time.

Sprockets Supplier in the Netherlands

RP Techniek BV is the authorized sales representative for Ever-power Group, a distinguished manufacturer in the power transmission domain. We specialize in providing high-quality sprockets in the Netherlands, including the #40-2 1/2" Taper Bore Sprocket, designed for exceptional durability and performance across various applications. Our products undergo stringent quality checks to ensure they comply with industry standards, making them suitable for both commercial and industrial usage. In addition to our standard offerings, we provide customized solutions tailored to meet specific requirements. Our team is well-equipped to handle non-standard customizations, and we encourage all customers to reach out with their designs or samples for personalized sprocket manufacturing.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...