In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications of H124 Mill Chain

ÒÔÏÂÊÇH124 Mill ChainµÄ²ÎÊý£º

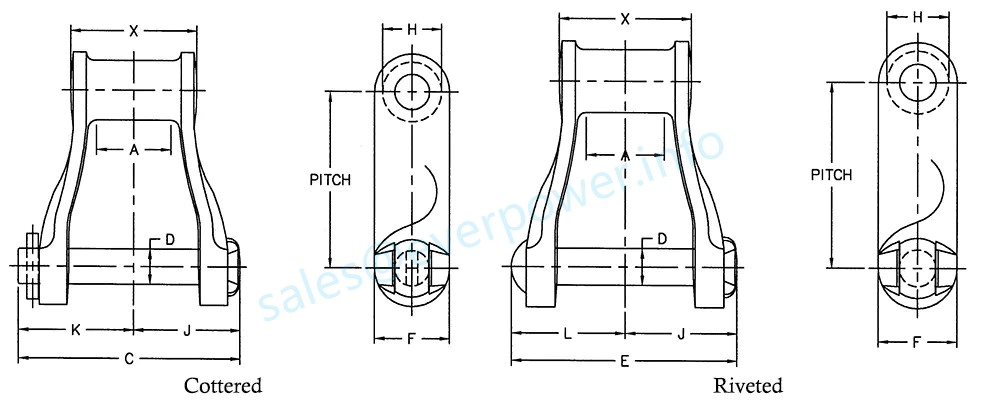

| CHAIN NO. | LINKS | PINS | PITCH IN INCHES | LINKS PER 10 FEET | WEIGHT PER FOOT LBS. | AVERAGE ULTIMATE STRENGTH LBS. | RECOMMENDED MAXIMUM WORKING LOAD LBS. | CHAIN CONSTRUCTION | AVAILABLE ATTACHMENTS | MAXIMUM ALLOWABLE SPROCKET FACE A | OVERALL WIDTH¡ª COTTERED C | DIAMETER OF PIN D | OVERALL WIDTH¡ª RIVETED E | HEIGHT OF SIDEBARS F | DIAMETER OF BARREL H | HEAD OF PIN TO CENTER LINE J | END OF PIN TO CENTER LINE¡ª COTTERED K | END OF PIN TO CENTER LINE¡ª RIVETED L | BEARING LENGTH X |

| H 60 | ALL NUMBERS A-L Primal |

ALL NUMBERS Carbon Steel, Heat-Treated | 2.308 | 52 | 2.1 | 9450 | 1560 | Riveted or Cottered | H2, K1 | 0.75 | 2.62 | 0.312 | 2.62 | 0.75 | 0.75 | 1.25 | 1.38 | 1.38 | 1.50 |

| H 74 | 2.609 | 46 | 3.0 | 13500 | 1850 | Riveted or Cottered | F4 | 1.00 | 3.12 | 0.375 | 2.88 | 1.00 | 0.88 | 1.50 | 1.62 | 1.62 | 1.66 | ||

| H 78 | 2.609 | 46 | 4.2 | 22200 | 2810 | Riveted or Cottered | A1, F4, F8, G19, H1, H2, K1, K2 | 1.12 | 3.31 | 0.500 | 3.19 | 1.12 | 0.88 | 1.56 | 1.62 | 1.62 | 1.88 | ||

| H 79 | 2.609 | 46 | 4.8 | 24300 | 2810 | Riveted or Cottered | None | 1.12 | 3.31 | 0.500 | 3.19 | 1.12 | 0.88 | 1.56 | 1.62 | 1.62 | 1.88 | ||

| H 82 | 3.075 | 39 | 5.5 | 27000 | 3580 | Riveted or Cottered | K2 | 1.25 | 3.88 | 0.562 | 3.88 | 1.25 | 1.22 | 1.88 | 2.00 | 2.00 | 2.12 | ||

| H 87 | 4.000 | 30 | 6.5 | 33750 | 4450 | Riveted or Cottered | None | 1.50 | 4.38 | 0.625 | 4.19 | 1.38 | 1.38 | 2.06 | 2.12 | 2.12 | 2.38 | ||

| H 124 | 4.000 | 30 | 8.8 | 40500 | 6180 | Riveted or Cottered | K2 | 1.62 | 4.88 | 0.750 | 4.75 | 1.56 | 1.44 | 2.25 | 2.50 | 2.50 | 2.75 |

Introduction

The H124 Mill Chain is a cutting-edge, high-performance product specifically designed for industrial milling applications. With its exceptional durability and precision engineering, this chain delivers unparalleled performance, making it the ideal choice for demanding mill operations.

Superior Strength and Wear Resistance

Our H124 Mill Chain is constructed using advanced alloy steel, providing superior strength and wear resistance. This ensures that the chain can withstand the harsh operating conditions of milling processes, delivering reliable performance and exceptional longevity.

Precision Engineering

Each link of the H124 Mill Chain is meticulously crafted with precision engineering techniques, ensuring optimal performance and smooth operation. The precise design minimizes friction and wear, allowing for efficient energy transfer and reducing downtime for maintenance.

Advanced Lubrication System

The H124 Mill Chain incorporates an advanced lubrication system that ensures continuous lubrication to minimize friction and wear. This innovative feature not only extends the lifespan of the chain but also reduces the need for frequent lubrication, resulting in cost savings and improved efficiency.

Enhanced Safety Features

Safety is a top priority in mill operations, and the H124 Mill Chain is designed with this in mind. It features enhanced safety features such as a secure locking mechanism and superior load-bearing capacity, providing a reliable and secure solution for your milling needs.

Application Versatility

Whether you are involved in the production of lumber, paper, or any other milling process, the H124 Mill Chain is versatile enough to meet your specific requirements. Its adaptability and rugged construction make it suitable for a wide range of applications, ensuring optimal performance in various industrial settings.

Choose Our Malleable Casting Chains

RP Techniek BV, as the Dutch sales agent of Ever-power Group, offers a wide range of malleable cast iron chains. Our H124 Mill Chain, in particular, showcases the unique selling points of our malleable casting chains.

With a strong emphasis on product quality and exceptional service, our chains stand out in the market. Crafted with precision and durability, they guarantee reliable performance and long-lasting operation. Our production capabilities further reinforce our commitment to delivering top-notch products.

In addition to the H124 Mill Chain, we also provide various other types of casting chains. From heavy-duty applications to specialized requirements, our diverse range ensures that we have the perfect solution for your needs.

Sprockets for Sale

When it comes to H124 Mill Chain, we offer a wide range of compatible sprockets to meet your needs. Our sprockets are designed to provide excellent durability and precision, ensuring smooth operation and maximum efficiency for your mill chain system.

At our company, we take pride in offering a wide selection of sprockets for various applications. Whether you require standard sprockets, special-order sprockets, or customized sprockets, we have you covered. Our sprockets are available in different sizes, tooth counts, and materials to suit different operating conditions and requirements.

With our extensive inventory, you can find the perfect sprocket for your H124 Mill Chain, ensuring optimal performance and longevity. We understand the importance of reliable equipment in your operations, and our sprockets are built to meet the highest industry standards.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...