In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

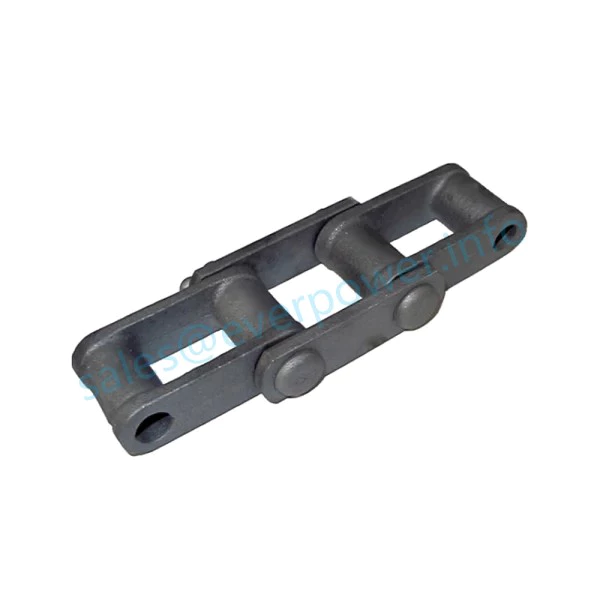

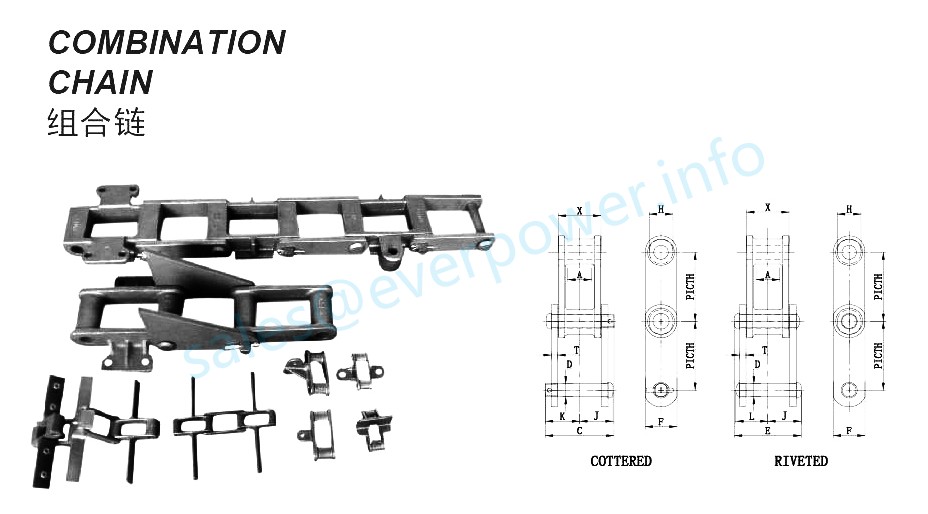

Specifications of C102B Combination Chain

- Material: High-quality steel alloy

- Chain Pitch: 25.4mm

- Breaking Load: 36600N

- Weight: 1.2kg/m

- Surface Treatment: Self-color, blackened, galvanized, or as per customer's requirements

- Application: Suitable for conveying heavy-duty materials in industries such as mining, agriculture, construction, etc.

| Chain No. | Pitch In Inches | Per Weight Foot Lbs | Average Ultimate Strength Lbs. | Maximum Working Load Lbs. | A | C | D | E | F | H | N | T | X | Available Attachments |

| C 55 | 1.631 | 2.20 | 9000 | 1400 | 0.69 | 2.06 | 0.375 | 1.97 | 0.75 | 0.72 | ¡ª | 0.19 | 1.25 | A22,G19,F30,K1 |

| C 55L | 1.631 | 2.50 | 11000 | 1400 | 0.69 | 2.06 | 0.375 | 1.97 | 0.75 | 0.72 | ¡ª | 0.19 | 1.25 | None |

| C 60 | 2307.000 | 3.00 | 16000 | 2620 | 0.88 | 2.94 | 0.500 | 2.88 | 1.00 | 0.75 | ¡ª | 0.25 | 1.69 | None |

| C 77 | 2.308 | 2.30 | 11000 | 1640 | 0.69 | 2.38 | 0.437 | 2.25 | 0.88 | 0.72 | ¡ª | 0.19 | 1.25 | F2 K1 |

| C 188 | 2.609 | 3.65 | 14000 | 2350 | 0.94 | 2.69 | 0.500 | 2.50 | 1.12 | 0.88 | ¡ª | 0.25 | 1.56 | F2,G6,K1,K2,S1,G19 |

| BRH 188 | 2.609 | 4.80 | 14000 | 2350 | 0.94 | 2.69 | 0.500 | 2.50 | 1.12 | 0.88 | 3.12 | 0.25 | 1.56 | None |

| C 131 | 3.075 | 6.65 | 24000 | 3880 | 1.12 | 3.75 | 0.625 | 3.50 | 1.50 | 1.22 | ¡ª | 0.38 | 2.06 | F2,G6,K2 |

| C 102B | 4.000 | 6.75 | 24000 | 5400 | 2.00 | 4.56 | 0.625 | 4.38 | 1.50 | 0.97 | ¡ª | 0.38 | 2.91 | K2 |

| C 1021/2 | 4.040 | 9.50 | 38600 | 6530 | 2.00 | 5.00 | 0.750 | 4.38 | 1.75 | 1.38 | ¡ª | 0.38 | 2.91 | K2,S1 |

| C 11 | 4.760 | 9.80 | 36000 | 7590 | 2.38 | 5.44 | 0.750 | 5.00 | 1.75 | 1.44 | ¡ª | 0.38 | 3.38 | K2,S1 |

| C111C | 4.760 | 9.40 | 45000 | 7590 | 2.38 | 5.44 | 0.750 | 5.00 | 1.75 | 1.44 | ¡ª | 0.38 | 3.38 | K2,S1 |

| C110 | 6.000 | 6.20 | 24000 | 5380 | 1.94 | 4.56 | 0.625 | 4.38 | 1.50 | 1.25 | ¡ª | 0.38 | 2.88 | K2 |

| C133 | 6.000 | 8.80 | 36000 | 5900 | 1.25 | 4.31 | 0.875 | 4.00 | 2.00 | 1.75 | ¡ª | 0.38 | 2.88 | None |

| C132 | 6.050 | 14.50 | 50000 | 11250 | 3.04 | 6.75 | 1.000 | 6.50 | 2.00 | 1.72 | ¡ª | 0.5 | 4.31 | K2,F4,F10,AM116 |

| PW132 | 6.050 | 16.10 | 65000 | 11250 | 3.04 | 6.75 | 1.000 | 6.50 | 2.00 | 1.72 | 5.88 | 0.5 | 4.31 | S1 |

| MBP132 | 6.050 | 15.70 | 65000 | 11250 | 3.04 | 6.75 | 1.000 | 6.50 | 2.00 | 1.72 | 5.88 | 0.5 | 4.31 | S1 |

| MBP132C | 6.050 | 15.70 | 65000 | 11250 | 3.04 | 6.75 | 1.000 | 6.50 | 2.00 | 1.72 | 5.88 | 0.5 | 4.31 | S1 |

Introduction

The C102B Combination Chain is a highly versatile and durable chain that is designed to meet the demanding needs of various industries. This chain is known for its exceptional strength and reliability, making it an ideal choice for applications that require heavy-duty performance. With its unique design and advanced features, the C102B Combination Chain offers superior performance and long-lasting durability.

1. Superior Strength

The C102B Combination Chain is engineered to provide superior strength and load-bearing capabilities. Its high-quality materials and precise manufacturing process ensure that it can withstand heavy loads and extreme conditions. This chain is specifically designed to handle demanding applications that require maximum strength and durability.

2. Versatile Applications

With its versatile design, the C102B Combination Chain can be used in a wide range of applications. Whether it's in the automotive industry, manufacturing plants, or agricultural settings, this chain is suitable for various tasks. Its reliable performance and adaptability make it an excellent choice for different industries.

3. Advanced Technology

The C102B Combination Chain incorporates advanced technology to enhance its performance and durability. It features innovative design elements that reduce wear and tear, increase efficiency, and minimize maintenance requirements. This chain is built to deliver exceptional performance even in the most challenging environments.

4. Enhanced Durability

Designed to withstand continuous use and harsh conditions, the C102B Combination Chain offers enhanced durability. Its robust construction and corrosion-resistant materials ensure long-lasting performance, reducing the need for frequent replacements. This chain is built to endure the rigors of demanding applications.

5. Precise Engineering

The C102B Combination Chain is meticulously engineered to meet the highest standards of quality and precision. Every component is carefully crafted to ensure optimal performance and reliability. With its precise engineering, this chain provides consistent and efficient operation.

6. Easy Installation and Maintenance

The C102B Combination Chain is designed for easy installation and maintenance. Its user-friendly design allows for quick and hassle-free setup, saving valuable time and resources. Additionally, this chain requires minimal maintenance, reducing overall downtime and costs.

Choose Our Malleable Casting Chains

RP Techniek BV is the Netherlands sales agent of Ever-power Group. Our malleable casting chains, such as the C102B combination chain, have unique selling points that set us apart from the competition. Our products are of exceptional quality, and we are committed to providing excellent customer service.

Our malleable casting chains are made of high-quality cast iron, which results in superior durability and strength. We have a proven track record of providing reliable and long-lasting products that meet the highest industry standards. Our production capabilities are top-notch, and we have the expertise to manufacture custom chains to meet your specific needs.

In addition to our malleable casting chains, we offer a wide range of other casting chains for sale. These include but are not limited to, stainless steel chains, alloy chains, and welded steel chains. Whatever your needs may be, we have the perfect chain to fit your requirements.

Please take a look at the image below to see the quality of our products for yourself.

Sprockets for Sale

When it comes to choosing the right sprocket for your C102B combination chain, there are a few factors to consider. The size of the chain, the number of teeth on the sprocket, and the material it's made from are all important. At our company, we offer a wide variety of sprockets to meet your needs.

For the C102B chain, we recommend using a hardened steel sprocket with a black oxide finish. This combination provides excellent wear resistance and helps prevent corrosion. Depending on your application, we can supply sprockets with anywhere from 10 to 100 teeth, in a range of bore sizes to fit your shaft.

In addition to the C102B chain, we also offer sprockets for a variety of other chain types and sizes. From ANSI standard roller chains to specialty agricultural chains, we have it all. Our sprockets are made from a variety of materials, including steel, stainless steel, and plastic, to suit your specific needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...