Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

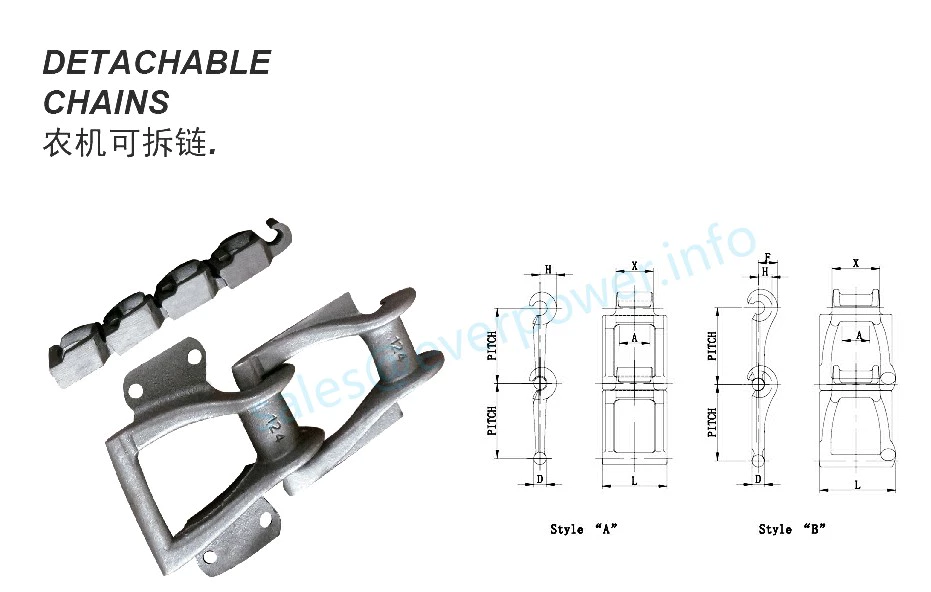

Specifications of 57 Casting Detachable Chain

- Material: High-quality cast iron

- Chain Pitch: 57mm

- Chain Width: 30mm

- Breaking Load: 48.5KN

- Weight per meter: 11.5kg

| CHAIN NO. | PITCH IN INCHES |

HEIGHT PER FOOT LBS |

AVERAGE ULTIMATE STRENGTH LBS |

MAXIMUM WORKING LOAD LBS. |

A | C | D | E | ?F | H | ?L | X | AVAILABLE ATTACHMENTS |

| 25 | 0.902 | 2.4 | 700 | 120 | 0.38 | 0.14 | ¡ª¡ª | 0.20 | ?0.78 | 0.41 | A1-R.A1-L | ||

| 32 | 1.154 | 3.5 | 1,100 | 185 | 0.50 | 0.17 | ¡ª¡ª | 0.25 | ?0.97 | 0.58 | A1-R.A1-L.K1 | ||

| 34 | 1.398 | 4.0 | 1.300 | 220 | 0.50 | 0.19 | 1.25 | 0.56 | None | ||||

| 42 | 1.375 | 5.5 | 1.600 | 270 | 0.62 | 0.22 | ¡ª¡ª | 0.28 | 1.28 | 0.77 | A1-R,A1-L.K1 | ||

| 45 | 1.630 | 5.2 | 1.700 | 285 | 0.69 | 0.22 | ¡ª¡ª | 0.30 | ?1.31 | 0.80 | A1-R.A1-L.K1 | ||

| 50 | 1.381 | 7.1 | 1.900 | 320 | 0.63 | 0.27 | 0.33 | ?1.31 | 0.62 | None | |||

| 51 | 1.155 | 7.0 | 1.900 | 320 | 0.56 | 0.27 | ¡ª¡ª | 0.36 | ?1.25 | 0.67 | K1 | ||

| S51 | 1.136 | 7.B | 1.900 | 315 | 0.56 | 0.27 | ¡ª¡ª | 0.30 | ?1.06 | 0.64 | None | ||

| 52 | 1.506 | 8.0 | 2,300 | 385 | 0.62 | 0.27 | ¡ª¡ª | 0.34 | ?1.53 | 0.83 | A1.D5,K1 | ||

| 55 | 1.631 | 7.2 | 2,300 | 385 | 0.69 | 0.27 | ¡ª¡ª | 0.36 | ?1.41 | 0.81 | A1-R/L,D5-R/L,C1.F2,G27-R/L,K1,C | ||

| 57 | 2.308 | 8.7 | 2.900 | 485 | 0.75 | 0.27 | ¡ª¡ª | 0.41 | ?1.81 | 1.09 | A1-R,A1-L.F2 | ||

| 62 | 1.654 | 10.6 | 3.200 | 535 | 0.81 | 0.31 | 0.41 | ?1.66 | 0.97 | A1-R/L,A12-R/L,05-R/L.K1,K2,F2 | |||

| 67 | 2.308 | 8.6 | 2.900 | 485 | 0.69 | 0.31 | ?0.53 | 0.41 | ?2.03 | 1.36 | None | ||

| 75 | 2.609 | 13.4 | 4,100 | 690 | 0.94 | 0.41 | ¡ª¡ª | 0.44 | ?2.09 | 1.12 | D5-R.D5-L | ||

| 77 | 2.297 | 14.5 | 3.600 | 600 | 0.69 | 0.39 | ?0.61 | 0.36 | ?2.22 | 1.42 | A1-R.A1-L.D5.F2,K1 | ||

| 78 | 2.609 | 18.8 | 5.500 | 920 | 0.94 | 0.42 | ?0.66 | 0.44 | ?2.62 | 1.62 | K1 | ||

| 88 | 2.609 | 24.0 | 6.400 | 1,070 | 0.94 | 0.48 | ?0.78 | 0.44 | ?2.75 | 1.78 | F2.K1 | ||

| 103 | 3.075 | 40.0 | 10,000 | 1,670 | 1.12 | 0.58 | ?1.00 | 0.61 | ?3.28 | 2.03 | F2.F8,K1,K2,F2 | ||

| 114 | 3.250 | 53.0 | 12.000 | 2.000 | 1.13 | 0.66 | ?0.17 | 0.81 | ?3.28 | 2.03 | None | ||

| 124 | 4.063 | 66.0 | 17.000 | 2,830 | 1.25 | 0.77 | ?1.31 | 0.68 | ?4.06 | 2.31 | F8.K1,K2 |

57 Casting Detachable Chain is a high-quality industrial chain that is widely used in various industries such as construction, mining, and agriculture. It is known for its durability, strength, and resistance to wear and tear. This detachable chain is made from high-quality cast steel that is designed to withstand heavy loads and extreme conditions.

Construction

The 57 Casting Detachable Chain is made from high-quality cast steel, which makes it incredibly strong and durable. It is designed to withstand heavy loads and can operate in extreme conditions without being damaged. The chain is constructed using a series of interlocking links that are held together with pins and cotters. This design allows for easy assembly and disassembly of the chain, making it an ideal choice for applications where the chain needs to be frequently replaced or repaired.

Design

The design of the 57 Casting Detachable Chain is based on the principle of maximum strength and durability. The chain is designed to distribute the load evenly across all the links, which helps to prevent stress and wear on individual links. The chain is also designed to reduce friction and wear, which helps to prolong its lifespan and reduce maintenance costs.

Applications

The 57 Casting Detachable Chain is used in a variety of applications across different industries. It is commonly used in construction equipment such as bulldozers, excavators, and cranes. It is also used in mining equipment such as conveyors and crushers. In the agricultural industry, it is used in equipment such as tractors and combines.

Maintenance

Maintaining the 57 Casting Detachable Chain is essential to ensure its longevity and performance. Regular cleaning and lubrication of the chain are necessary to prevent rust and wear. It is also important to inspect the chain regularly for any signs of damage or wear and to replace any damaged or worn links immediately.

Conclusion

The 57 Casting Detachable Chain is a high-quality industrial chain that is widely used across various industries. Its strength, durability, and resistance to wear and tear make it an ideal choice for heavy-duty applications. With regular maintenance, this chain can provide reliable performance for many years, making it a cost-effective solution for industrial operations.

Choose Our Malleable Casting Chains

RP Techniek BV is the Dutch sales agent of Ever-power Group. We take pride in presenting our Malleable Casting Chains, which are highly sought after in the market. Our 57 Casting Detachable Chain is a perfect example of the unique selling point of our malleable cast iron chains, which are known for their exceptional quality and durability.

We are committed to providing our customers with the best in class products and services. Our production strength lies in our state-of-the-art manufacturing facilities, which are equipped with the latest technology. Our highly skilled and experienced workforce ensures that each chain is made with precision and accuracy.

Apart from our Malleable Casting Chains, we offer a wide range of other casting chains that cater to different industries. Our chains are highly versatile and can be customized to meet specific customer requirements.

As a company, we focus on building long-term relationships with our customers. We take pride in our commitment to quality and timely delivery. We believe in going the extra mile to ensure that our customers are satisfied with our products and services.

Please visit our website to learn more about our products and services. We look forward to serving you soon.

Sprockets for Sale

When it comes to finding the perfect match for your 57 Casting Detachable Chain, look no further than our wide selection of sprockets. At our company, we pride ourselves on providing a variety of different types of sprockets to meet your specific needs.

Whether you're looking for a small sprocket with fewer teeth for faster speeds or a larger sprocket with more teeth for increased torque, we have you covered. Our sprockets are made from high-quality materials, ensuring durability and long-lasting performance.

With our extensive inventory, you'll find sprockets in various sizes and configurations to fit your application. From standard pitch to double pitch, we offer a range of options to suit different chain types and sizes.

Take a look at the image below to get a glimpse of our exceptional sprocket collection:

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...