Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

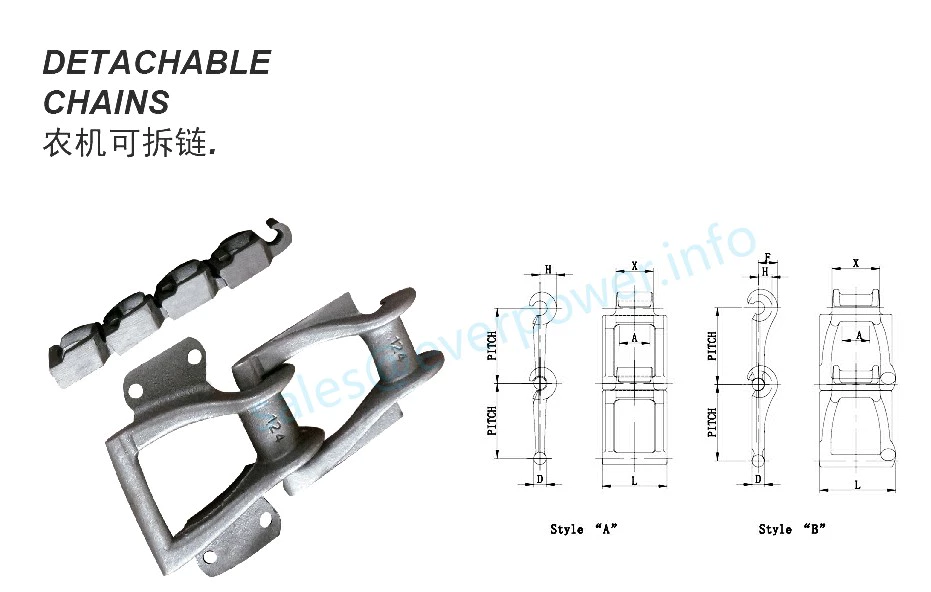

Specifications for 55 Casting Detachable Chain

- Chain Pitch: 63.5mm

- Pin Diameter: 12.07mm

- Plate Height: 57.15mm

- Plate Thickness: 6.35mm

- Average Tensile Strength: 276.9 kN

| CHAIN NO. | PITCH IN INCHES |

HEIGHT PER FOOT LBS |

AVERAGE ULTIMATE STRENGTH LBS |

MAXIMUM WORKING LOAD LBS. |

A | C | D | E | ?F | H | ?L | X | AVAILABLE ATTACHMENTS |

| 25 | 0.902 | 2.4 | 700 | 120 | 0.38 | 0.14 | ¡ª¡ª | 0.20 | ?0.78 | 0.41 | A1-R.A1-L | ||

| 32 | 1.154 | 3.5 | 1,100 | 185 | 0.50 | 0.17 | ¡ª¡ª | 0.25 | ?0.97 | 0.58 | A1-R.A1-L.K1 | ||

| 34 | 1.398 | 4.0 | 1.300 | 220 | 0.50 | 0.19 | 1.25 | 0.56 | None | ||||

| 42 | 1.375 | 5.5 | 1.600 | 270 | 0.62 | 0.22 | ¡ª¡ª | 0.28 | 1.28 | 0.77 | A1-R,A1-L.K1 | ||

| 45 | 1.630 | 5.2 | 1.700 | 285 | 0.69 | 0.22 | ¡ª¡ª | 0.30 | ?1.31 | 0.80 | A1-R.A1-L.K1 | ||

| 50 | 1.381 | 7.1 | 1.900 | 320 | 0.63 | 0.27 | 0.33 | ?1.31 | 0.62 | None | |||

| 51 | 1.155 | 7.0 | 1.900 | 320 | 0.56 | 0.27 | ¡ª¡ª | 0.36 | ?1.25 | 0.67 | K1 | ||

| S51 | 1.136 | 7.B | 1.900 | 315 | 0.56 | 0.27 | ¡ª¡ª | 0.30 | ?1.06 | 0.64 | None | ||

| 52 | 1.506 | 8.0 | 2,300 | 385 | 0.62 | 0.27 | ¡ª¡ª | 0.34 | ?1.53 | 0.83 | A1.D5,K1 | ||

| 55 | 1.631 | 7.2 | 2,300 | 385 | 0.69 | 0.27 | ¡ª¡ª | 0.36 | ?1.41 | 0.81 | A1-R/L,D5-R/L,C1.F2,G27-R/L,K1,C | ||

| 57 | 2.308 | 8.7 | 2.900 | 485 | 0.75 | 0.27 | ¡ª¡ª | 0.41 | ?1.81 | 1.09 | A1-R,A1-L.F2 | ||

| 62 | 1.654 | 10.6 | 3.200 | 535 | 0.81 | 0.31 | 0.41 | ?1.66 | 0.97 | A1-R/L,A12-R/L,05-R/L.K1,K2,F2 | |||

| 67 | 2.308 | 8.6 | 2.900 | 485 | 0.69 | 0.31 | ?0.53 | 0.41 | ?2.03 | 1.36 | None | ||

| 75 | 2.609 | 13.4 | 4,100 | 690 | 0.94 | 0.41 | ¡ª¡ª | 0.44 | ?2.09 | 1.12 | D5-R.D5-L | ||

| 77 | 2.297 | 14.5 | 3.600 | 600 | 0.69 | 0.39 | ?0.61 | 0.36 | ?2.22 | 1.42 | A1-R.A1-L.D5.F2,K1 | ||

| 78 | 2.609 | 18.8 | 5.500 | 920 | 0.94 | 0.42 | ?0.66 | 0.44 | ?2.62 | 1.62 | K1 | ||

| 88 | 2.609 | 24.0 | 6.400 | 1,070 | 0.94 | 0.48 | ?0.78 | 0.44 | ?2.75 | 1.78 | F2.K1 | ||

| 103 | 3.075 | 40.0 | 10,000 | 1,670 | 1.12 | 0.58 | ?1.00 | 0.61 | ?3.28 | 2.03 | F2.F8,K1,K2,F2 | ||

| 114 | 3.250 | 53.0 | 12.000 | 2.000 | 1.13 | 0.66 | ?0.17 | 0.81 | ?3.28 | 2.03 | None | ||

| 124 | 4.063 | 66.0 | 17.000 | 2,830 | 1.25 | 0.77 | ?1.31 | 0.68 | ?4.06 | 2.31 | F8.K1,K2 |

1. Overview of 55 Casting Detachable Chain

The 55 Casting Detachable Chain is a versatile and high-quality product that revolutionizes the field of industrial chains. It is designed to provide exceptional performance and durability in various applications. This chain is specifically engineered for heavy-duty usage and offers superior strength and reliability.

2. Construction and Design

The 55 Casting Detachable Chain features a unique construction and design that sets it apart from traditional chains. It is manufactured using advanced casting techniques, ensuring precise dimensions and consistent quality. The chain is composed of individual detachable links that allow for easy assembly, disassembly, and maintenance.

2.1 Casting Process

In the production process, molten metal is poured into a customized mold, resulting in a solid and interconnected chain structure. This casting method enhances the chain's overall strength, making it highly resistant to wear, corrosion, and fatigue.

2.2 Detachable Link Design

The detachable link design of the 55 Casting Detachable Chain enables quick and efficient maintenance. Each link can be easily removed, replaced, or adjusted without the need for special tools. This feature not only saves time but also reduces downtime and enhances productivity in various industrial applications.

3. Key Features

The 55 Casting Detachable Chain offers a range of impressive features, making it an ideal choice for demanding industrial environments.

3.1 Exceptional Strength

Thanks to its robust construction and high-quality materials, the 55 Casting Detachable Chain boasts exceptional strength and load-carrying capacity. It can withstand heavy loads, intense pressures, and harsh operating conditions without compromising performance.

3.2 Enhanced Durability

With its superior resistance to wear, corrosion, and fatigue, the 55 Casting Detachable Chain offers enhanced durability and longevity. It is designed to deliver consistent performance even in challenging environments, ensuring minimal maintenance and replacement costs.

3.3 Versatile Applications

The 55 Casting Detachable Chain finds applications in a wide range of industries, including manufacturing, mining, agriculture, and construction. Its adaptability and reliability make it suitable for conveying heavy materials, driving machinery, and supporting various industrial processes.

4. Advantages

Choosing the 55 Casting Detachable Chain brings numerous advantages to industrial operations:

4.1 Increased Efficiency

The detachable link design allows for quick and easy maintenance, reducing downtime and increasing productivity. This chain's exceptional strength and durability enhance overall operational efficiency, ensuring smooth workflow and optimal performance.

4.2 Cost Savings

The 55 Casting Detachable Chain's longevity and resistance to wear result in reduced maintenance and replacement expenses. Its reliability minimizes the risk of unexpected failures, leading to improved cost-effectiveness in the long run.

4.3 Customization Options

Customers can benefit from various customization options for the 55 Casting Detachable Chain, such as different sizes, coatings, and attachment accessories. This flexibility ensures compatibility with specific equipment requirements, meeting the diverse needs of different industries.

5. Conclusion

The 55 Casting Detachable Chain is an innovative and reliable solution for industrial applications that demand superior strength, durability, and efficiency. Its unique construction, detachable link design, and exceptional performance make it a valuable asset in various industries. Invest in the 55 Casting Detachable Chain to enhance productivity, reduce costs, and elevate your industrial operations to new heights.

Choose Our Malleable Casting Chains

RP Techniek BV is the official sales agent for Ever-power Group in the Netherlands. Our malleable casting chains, specifically the 55 Casting Detachable Chain, have unique selling points that set them apart from our competitors. Our chains are made of high-quality malleable cast iron, ensuring durability and longevity. In addition, we pride ourselves on providing exceptional customer service to our clients.

At RP Techniek BV, we have the production capabilities to meet any casting chain needs that you may have. Our extensive inventory includes a variety of other types of casting chains that are available for purchase. We are committed to providing our clients with the best products and services possible.

Sprockets for Sale

When it comes to the 55 Casting Detachable Chain, finding the perfect matching sprocket is crucial. At our company, we offer a wide range of different types of sprockets for sale to meet your specific needs.

Our sprockets are designed with precision and durability in mind. Whether you require a standard sprocket or a custom-made one, we have got you covered. With our extensive selection, you can find the perfect sprocket to ensure smooth and efficient operation of your 55 Casting Detachable Chain.

Our sprockets are made from high-quality materials, ensuring long-lasting performance and reliability. We understand the importance of finding the right sprocket to optimize the functionality of your equipment, and our knowledgeable team is here to assist you in making the best choice.

Choose our company for all your sprocket needs. We guarantee top-notch quality, competitive prices, and excellent customer service. Don't hesitate to contact us for more information or to place an order.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...