What Are the Signs of Wear in EPRV Series Small Worm Gearboxes?

giriiş

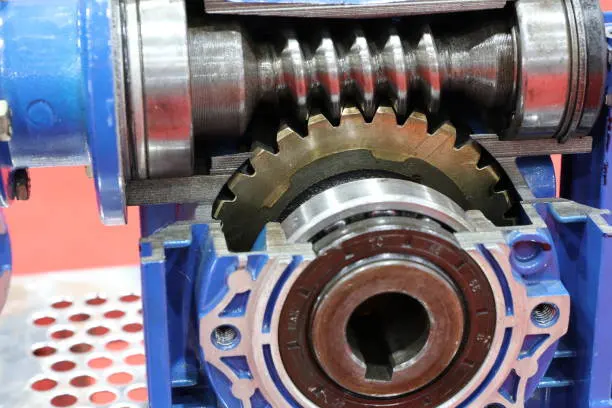

Worm gearboxes are widely used in various industries due to their efficiency and compact design. However, like any mechanical component, they are subject to wear and tear over time. In this article, we will explore the signs of wear in EPRV series small worm gearboxes and discuss their implications.

1. Abnormal Noise

One of the first signs of wear in a worm gearbox is the presence of abnormal noise during operation. This noise can be described as rattling, grinding, or whining, indicating that the gears are not meshing properly. It is essential to address this issue promptly to prevent further damage to the gearbox.

2. Increased Heat

Another indicator of wear in EPRV series small worm gearboxes is the generation of excessive heat. When the gears are worn out, there is increased friction, leading to heat buildup. Monitoring the temperature of the gearbox can help identify potential issues and prevent overheating.

3. Vibration

Worn gears can cause vibration in the worm gearbox, which can be felt through the housing or other connected components. This vibration is a result of the gears losing their precision and can lead to further damage if not addressed promptly.

4. Leakage of Lubricant

A common sign of wear in worm gearboxes is the leakage of lubricant. As the gears wear out, the sealing between the gearbox housing and the input/output shafts may become compromised, leading to lubricant leakage. Regular inspection of the gearbox for oil stains or dripping lubricant is crucial.

5. Decreased Efficiency

As wear progresses in EPRV series small worm gearboxes, their overall efficiency decreases. This can be observed through increased power consumption or a decrease in the output torque. Regular performance monitoring and comparative analysis can help identify any efficiency loss.

6. Gear Tooth Pitting

One specific type of wear in worm gearboxes is gear tooth pitting. This occurs when the gear teeth experience excessive pressure or repetitive impact, resulting in small pits or craters on their surface. Gear tooth pitting can lead to accelerated wear and eventual failure if not addressed in a timely manner.

7. Shaft Misalignment

Wear in worm gearboxes can cause shaft misalignment, which occurs when the input and output shafts are not perfectly aligned. This misalignment puts additional stress on the gears and bearings, leading to further wear and potential failure. Regular inspection and realignment are necessary to maintain optimum performance.

8. Gear Tooth Wear Pattern

Another visual sign of wear in worm gearboxes is the wear pattern on the gear teeth. Worn-out gears may exhibit uneven tooth wear, chipped edges, or signs of material fatigue. These wear patterns can provide valuable insights into the health of the gearbox and help diagnose potential issues.

9. Excessive Backlash

Backlash refers to the small amount of play or clearance between meshing gears. In EPRV series small worm gearboxes, excessive backlash can indicate wear in the gears or bearings. This can affect the accuracy and precision of the gearbox, compromising its performance.

10. Implications of Wear

The signs of wear discussed above can have several implications for EPRV series small worm gearboxes. Ignoring these signs can lead to further damage, reduced efficiency, and even complete gearbox failure. Regular maintenance, inspection, and timely replacement of worn-out components are essential to prolonging the lifespan of the gearbox and ensuring optimal performance.

Satılık Elektrik Motorları

The relationship between gearboxes and electric motors is symbiotic and crucial in various applications. Gearboxes, such as the EPRV series small worm gearboxes, play a vital role in reducing the speed and increasing the torque of the electric motor output. This enables the motor to deliver power more efficiently to the intended application.

At our company, we understand the importance of this relationship, and that's why we offer a wide range of electric motors for sale, perfectly matched with our gearboxes. Our electric motors are designed to provide optimal performance and efficiency, ensuring seamless integration with our gearbox products.

Hakkımızda

RP Techniek BV is the Netherlands sales agent of the Ever-power Group. We are a comprehensive transmission equipment manufacturer with over 25 years of experience in designing, manufacturing, and selling speed reducers. Our gearboxes, including the EPRV series small worm gearboxes, are highly regarded in the market and have gained a reputation for their superior quality, competitive pricing, and excellent customer service.

Our production capabilities are top-notch, with advanced equipment and testing facilities. We employ industry professionals and technicians who continuously strive for innovation in research, development, and manufacturing. Through standardized production management methods, we ensure strict quality control at every stage of gearbox production, delivering high-quality, energy-efficient, and stable products to our customers.

Our gearboxes find applications in various industries, including equipment, food, car washing, packaging, transmission, automation, solar energy, and more. We are proud to have earned the trust and satisfaction of our customers through our commitment to excellence.

Explore our products and discover the perfect solution for your transmission needs. Contact us today to inquire about our gearbox and electric motor offerings.

Soru & Cevap

Q: How often should I inspect my EPRV series small worm gearbox for wear?

A: Regular inspection is recommended, depending on the operating conditions and usage frequency. However, it is advisable to inspect the gearbox at least once every six months to detect any signs of wear early on.

Q: Can I replace individual gears in my EPRV series small worm gearbox?

A: In some cases, individual gears can be replaced. However, it is essential to consult the manufacturer's guidelines and seek professional assistance to ensure proper compatibility and performance.

Q: What lubricant should I use for my EPRV series small worm gearbox?

A: The recommended lubricant will depend on the specific gearbox model and operating conditions. It is best to refer to the manufacturer's recommendations or consult with their technical support team for the appropriate lubricant.

Q: Can wear in a worm gearbox be repaired?

A: In some cases, wear can be repaired by replacing worn-out components or performing necessary repairs. However, extensive wear or damage may require gearbox replacement. Professional assessment is crucial to determine the best course of action.

Q: What is the expected lifespan of an EPRV series small worm gearbox?

A: The lifespan of a worm gearbox depends on various factors, including operating conditions, maintenance practices, and load requirements. With proper care and maintenance, an EPRV series small worm gearbox can last for many years.

Editör: Zqq.