giriiş

EPRV series small worm gearboxes are widely used in various industries due to their compact design and efficient power transmission capabilities. The availability of custom gear ratios further enhances their versatility and suitability for different applications. In this article, we will explore the options for custom gear ratios in EPRV series small worm gearboxes and their significance in optimizing performance.

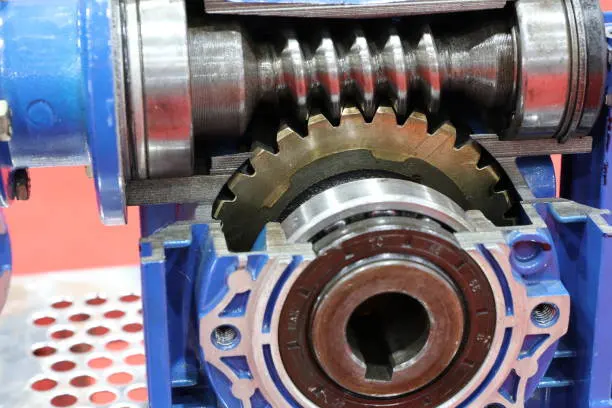

1. Understanding Gear Ratios

Gear ratios play a crucial role in determining the speed and torque characteristics of a gearbox. In EPRV series small worm gearboxes, the gear ratio is the ratio between the number of teeth on the worm gear and the number of teeth on the worm wheel. Different gear ratios can be achieved by varying the number of teeth on these components, allowing for customized performance.

1.1 Importance of Custom Gear Ratios

The ability to customize gear ratios in EPRV series small worm gearboxes is essential for achieving specific speed and torque requirements in different applications. By selecting the appropriate gear ratio, the gearbox can be optimized to deliver the desired output speed and torque, ensuring efficient and reliable operation.

2. Options for Custom Gear Ratios

EPRV series small worm gearboxes offer a wide range of options for custom gear ratios, allowing for precise tailoring of performance characteristics. Here are some of the available options:

2.1 High Gear Ratio

A high gear ratio, such as 60:1 or 80:1, provides increased torque output at the expense of reduced speed. This option is suitable for applications that require high torque, such as heavy-duty machinery or lifting equipment.

2.2 Low Gear Ratio

A low gear ratio, such as 10:1 or 20:1, offers higher speed output while sacrificing torque. This option is ideal for applications that demand fast rotation, such as conveyors or automated systems.

2.3 Customizable Gear Ratio Range

EPRV series small worm gearboxes can also be customized to provide a specific range of gear ratios. This allows for fine-tuning the gearbox to meet the exact requirements of the application, providing optimal performance and efficiency.

3. Importance of Custom Gear Ratios

The customization of gear ratios in EPRV series small worm gearboxes is of utmost importance for achieving efficient power transmission and ensuring the gearbox's compatibility with the driven equipment. Here are some key reasons why custom gear ratios matter:

3.1 Maximizing Efficiency

By selecting an appropriate gear ratio, the efficiency of the gearbox can be maximized, minimizing energy losses and improving overall system efficiency. This is particularly crucial for applications where energy consumption is a significant concern.

3.2 Tailoring Torque Output

Custom gear ratios allow for precise control over the torque output of the gearbox. This is essential for matching the torque requirements of the driven equipment, preventing unnecessary strain on the gearbox and ensuring reliable operation.

3.3 Optimizing Speed Requirements

By choosing the appropriate gear ratio, the gearbox can be optimized to deliver the desired speed output. This is crucial for applications where specific speed requirements must be met, such as conveyor systems or assembly lines.

Satılık Elektrik Motorları

The relationship between gearboxes and electric motors is symbiotic, with each complementing and enhancing the other's capabilities. Gearboxes enable the efficient transmission of power from electric motors to the driven equipment, ensuring the desired speed and torque characteristics are achieved. At our company, we not only provide high-quality EPRV series small worm gearboxes but also offer a wide range of electric motors for sale to meet the diverse needs of our customers.

Hakkımızda

RP Techniek BV is the Netherlands sales agent of Ever-power Group, a renowned comprehensive transmission equipment manufacturer. With over 25 years of experience in design, production, manufacturing, and sales of gearboxes, we have established ourselves as a trusted supplier in the global market. Our gearboxes are known for their exceptional quality, energy efficiency, and competitive prices, catering to customers in Europe, America, Africa, Asia, and other regions.

At RP Techniek BV, we take pride in our state-of-the-art production facilities and a team of industry professionals and technicians. We are committed to continuous innovation and strict quality control, ensuring that every gearbox we produce meets the highest standards. Our gearboxes find applications in various industries, including equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, and solar energy industry.

Soru & Cevap

Q: Can I customize the gear ratio of an EPRV series small worm gearbox?

A: Yes, EPRV series small worm gearboxes can be customized to achieve specific gear ratios according to your application requirements.

Q: What factors should I consider when selecting a gear ratio?

A: When selecting a gear ratio, factors such as desired output speed, torque requirements, and energy efficiency should be taken into consideration.

Q: Can I change the gear ratio of a gearbox after installation?

A: No, the gear ratio of a gearbox is fixed and cannot be changed without replacing the worm gear and worm wheel with components having a different number of teeth.

Q: How does the gear ratio affect the efficiency of a gearbox?

A: The gear ratio can impact the efficiency of a gearbox. Higher gear ratios may result in slightly lower efficiency due to increased friction and power losses.

Q: Are custom gear ratios more expensive than standard ratios?

A: The cost of custom gear ratios may vary depending on the complexity of the customization. However, it is important to consider the long-term benefits and improved performance that custom gear ratios can provide.

Editör: Zqq.