In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

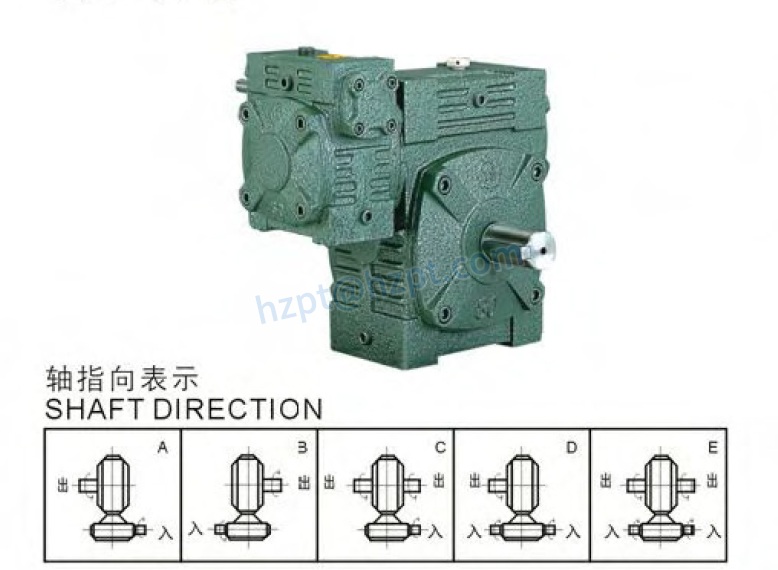

WPWE Series Double Stage Cast Iron Worm Gearbox

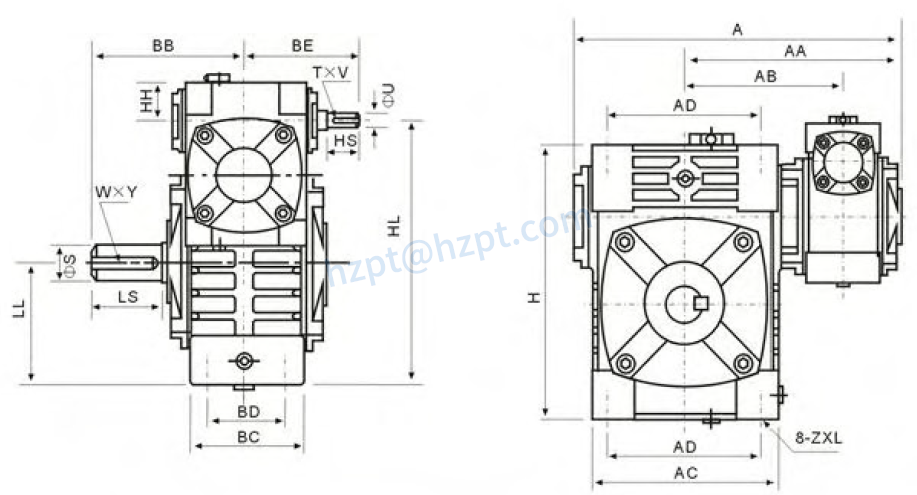

The WPWE Series Double Stage Cast Iron Worm Gearbox is a product designed for various industrial applications. It is composed of transmission parts, including a worm gear, worm, shaft, bearing, box, and other accessories. The gearbox has a sturdy and reliable construction, ensuring the correct relative position of transmission accessories and supporting heavy loads on the reducer.

The primary function of the worm gear and shaft is to transfer motion and power between two staggered shafts. The gearbox's housing is made of high-quality die-cast iron, providing excellent stability and durability. The worm is made of 20CrMn Ti with carburizing and quenching, ensuring a surface hardness of 56-62HRC. The shaft is made of chromium steel (45#), further enhancing the gearbox's performance.

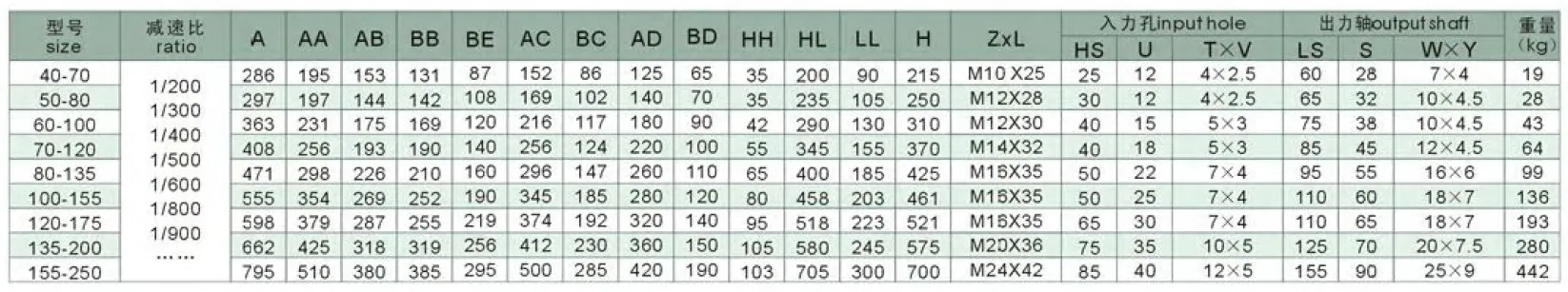

WPWE Series Worm Gearbox Specifications:

|

Type |

Worm Gearbox |

|

Örnek |

WPWE |

|

Ratio |

1:200, 300, 400, 500, 600, 800, 900 |

|

Color |

Blue/Red Or On Customer Request |

|

Material |

Housing: Die-Cast Iron cast |

|

Worm Gear-Copper-10-3# |

|

|

Worm-20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC |

|

|

Shaft-chromium steel-45# |

|

|

Packing |

Carton and Wooden Case |

|

Garanti |

1 Year |

|

Usages |

Industrial Machine: Food Stuff, Ceramics, CHEMICAL, Packing, Dyeing, Woodworking, Glass. |

|

Lubricant |

Synthetic&Mineral |

Materials and Functions of Some Accessories of Worm Gearbox:

The housing of the gearbox is made of aluminum alloy (seat: 025-090) or cast iron (seat: 110-250). The worm is made of 20Cr steel with carbon and nitrogen co-treatment, ensuring a tooth surface hardness of HRC60. The worm gear is specially equipped with wear-resistant nickel bronze. Various accessories, such as the oil cover/ventilator, bearing cover, oil seal, oil discharge screw plug, and

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...