In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine

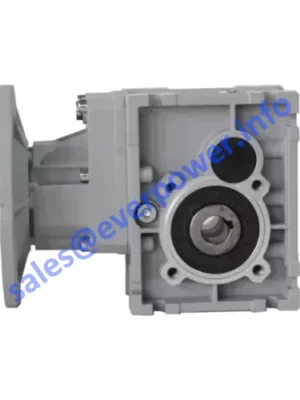

The EPRV050 worm gearmotor is custom-made for automated car wash systems. It is well-known for its simple setup, minimal noise output, extended durability, and superior protection rating. Featuring an IP56 protection rating, this gearbox is constructed for longevity. It supports motor capacities between 0.25kw and 0.75kw and includes corresponding flanges, providing adaptability to accommodate diverse customer requirements.

Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine

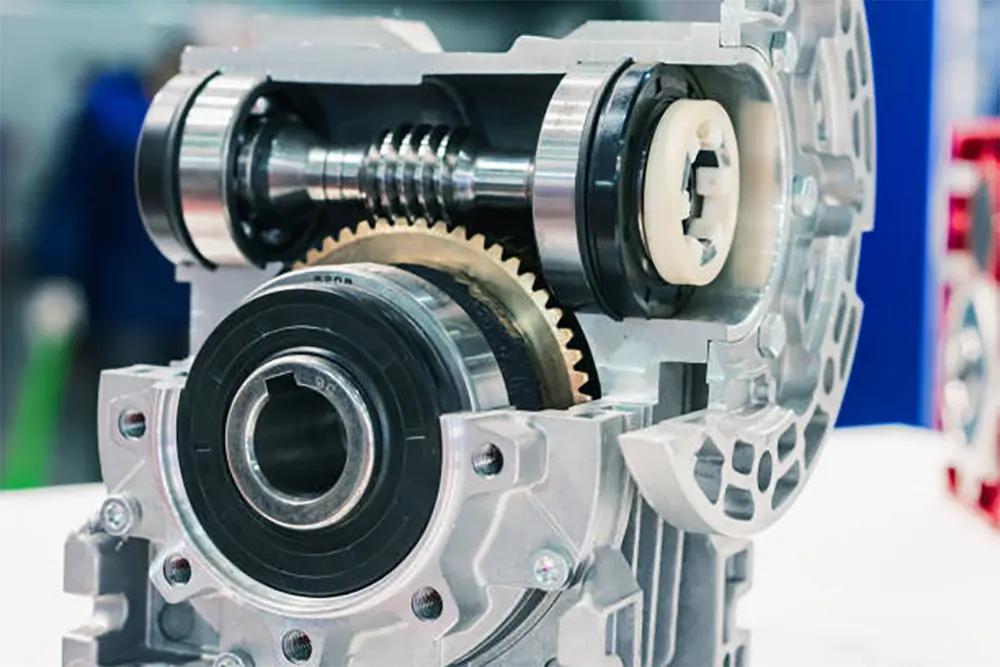

A Worm Gearbox for Rotary Brushes in an Automatic Car Washing Machine is a type of gearbox that is used to transmit power between perpendicular shafts. The gearbox consists of a worm gear and a worm wheel. The worm gear is a screw-like gear that drives the worm wheel, which has gear teeth that mesh with the worm gear. When the worm gear rotates, it drives the worm wheel, which in turn rotates the brush. The worm gear is designed to provide a large reduction in speed, making it ideal for use in automatic car washing machines. EPRV050 worm gear reducer provided by us is a durable gear unit for rotary brushes in automatic car washing machines.

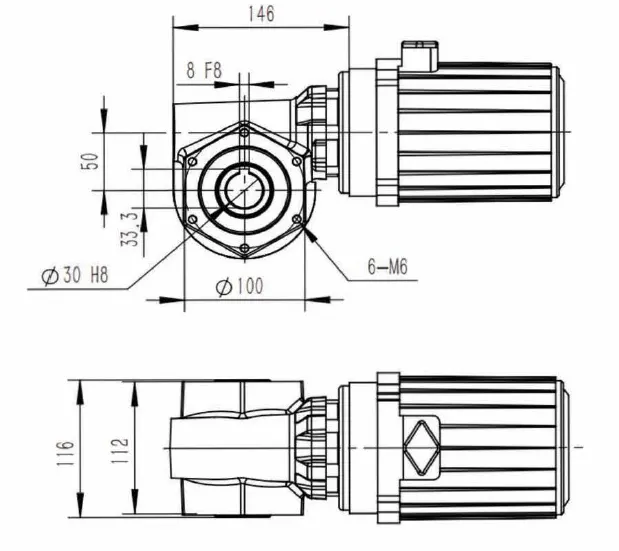

Details of EPRV050 Car Washer Reducer for Rotary Brushes

| Type | Ratio | Flange | Power |

| EPRV050 | 5 7.5 10 12 15 20 30 40 50 60 80 100 | 71B14 | 0.18KW 0.25KW 0.37KW 0.55KW 0.75KW 1.1KW |

| 80B14 |

| Type | i | n2/r/min | Mn2/Nm | Fr2/N | Motor | P1/kw | L/mm |

| EPRV050 | 5 | 280 | 17 | 1577 | 7134 | 0.55 | 180 |

| 280 | 23 | 1577 | 8024 | 0.75 | 205 | ||

| 7.5 | 187 | 25 | 1805 | 7134 | 0.55 | 180 | |

| 187 | 34 | 1805 | 8024 | 0.75 | 205 | ||

| 10 | 140 | 22 | 1987 | 7124 | 0.37 | 180 | |

| 140 | 32 | 1987 | 7134 | 0.55 | 180 | ||

| 140 | 44 | 1987 | 8024 | 0.75 | 205 | ||

| 12 | 117 | 26 | 2016 | 7124 | 0.37 | 180 | |

| 117 | 33 | 2016 | 7134 | 0.55 | 205 | ||

| 117 | 48 | 2016 | 8024 | 0.75 | 205 | ||

| 15 | 93 | 31 | 2274 | 7124 | 0.37 | 180 | |

| 93 | 46 | 2274 | 7134 | 0.55 | 180 | ||

| 93 | 63 | 2274 | 8024 | 0.75 | 205 | ||

| 20 | 70 | 27 | 2503 | 7114 | 0.25 | 180 | |

| 70 | 40 | 2503 | 7124 | 0.37 | 180 | ||

| 70 | 59 | 2503 | 7134 | 0.55 | 180 | ||

| 70 | 81 | 2503 | 8024 | 0.75 | 205 | ||

| 25 | 56 | 32 | 2696 | 7114 | 0.25 | 180 | |

| 56 | 48 | 2696 | 7124 | 0.37 | 180 | ||

| 56 | 71 | 2696 | 7134 | 0.55 | 180 | ||

| 30 | 47 | 37 | 2865 | 7114 | 0.25 | 180 | |

| 47 | 55 | 2865 | 7124 | 0.37 | 180 | ||

| 47 | 81 | 2865 | 7134 | 0.55 | 180 | ||

| 40 | 35 | 33 | 3153 | 7114 | 0.25 | 180 | |

| 35 | 46 | 3153 | 7124 | 0.37 | 180 | ||

| 35 | 68 | 3153 | 7134 | 0.55 | 180 | ||

| 50 | 28 | 54 | 3397 | 7114 | 0.25 | 180 | |

| 28 | 72 | 3397 | 7124 | 0.37 | 180 | ||

| 28 | 80 | 3397 | 7134 | 0.55 | 180 | ||

| 52 | 27 | 55 | 3482 | 7114 | 0.25 | 180 | |

| 27 | 73 | 3482 | 7124 | 0.37 | 180 | ||

| 27 | 82 | 3482 | 7134 | 0.55 | 180 | ||

| 60 | 23 | 60 | 3610 | 7114 | 0.25 | 180 | |

| 23 | 75 | 3610 | 7124 | 0.37 | 180 | ||

| 23 | 84 | 3610 | 7134 | 0.55 | 180 | ||

| 80 | 18 | 64 | 3973 | 7114 | 0.25 | 180 | |

| 18 | 77 | 3973 | 7124 | 0.37 | 180 | ||

| 18 | 89 | 3973 | 7134 | 0.55 | 180 | ||

| 100 | 14 | 68 | 4280 | 7114 | 0.25 | 180 | |

| 14 | 79 | 4280 | 7124 | 0.37 | 180 | ||

| 14 | 93 | 4280 | 7134 | 0.55 | 180 |

Features of EPRV050 Car Washer Reducer for Rotary Brushes

The EPRV050 Car Wash Gearmotor is engineered for automatic car wash systems, offering simple installation and quiet performance. It is built for durability, with a long service life and a high protection rating of up to IP56, making it resistant to tough environmental conditions. Designed to accommodate motor powers ranging from 0.25kw to 0.75kw, it comes with compatible flanges to meet various customer requirements and features a modular design for easy maintenance.

The gearmotor includes wheels made from SUS304+GcuSn12, ensuring excellent wear and corrosion resistance, and its compact design integrates well with most equipment layouts. It uses full-synthetic oil for lubrication, and the ADC12 aluminum housing, coated with powder paint, enhances corrosion resistance. Sealed with NOK oil seals and fitted with carburized and quenched worms, it delivers reliable performance and an IP67 protection rating, making it suitable for a wide range of conditions.

The Importance of Choosing the Right Worm Gearbox for Rotary Brushes in Automatic Car Washer

What to Consider When Choosing a Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine?

When choosing a Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine, there are several factors to consider. These include the application, the torque requirements, the gearbox ratio, and the operating environment.

How to Choose the Right Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine?

To choose the right Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine, it is essential to understand the application requirements. This includes the required torque, speed, and power transmission. The operating environment, including temperature, humidity, and exposure to water, should also be considered.

The Advantages of Using a High-Quality Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine

Using a high-quality Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine can provide several advantages. These include increased efficiency, reduced maintenance requirements, and longer service life.

Maintenance for Worm Gear Motors for Rotary Brushes in Automatic Car Washing Machine

Why is Maintenance Important for Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine?

Maintenance is essential for Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine to ensure optimal performance and longevity. Regular maintenance can prevent premature wear and damage to the gearbox.

How to Maintain a Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine?

To maintain a Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine, it is necessary to follow the manufacturer's maintenance instructions. This may include regular inspection and cleaning, lubrication, and replacement of worn or damaged parts.

Possible Problems and Solutions

| Problem | Solution |

|---|---|

| Excessive Noise | Check for loose or worn parts and tighten or replace as necessary. |

| Leaking Oil | Check for leaks in the gearbox and replace the seal if necessary. |

| Overheating | Check for proper lubrication and ventilation. |

| Low Torque Output | Check for worn or damaged parts and replace as necessary. |

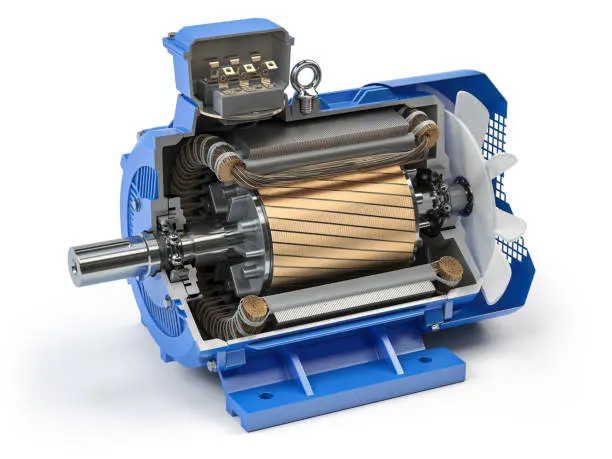

Motors For Car Wash Machine

The motor is an essential component of an automatic car washing machine. It provides the necessary power to drive the Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine. The motor and gearbox work together to ensure optimal performance and efficiency.

At our company, we offer a wide range of motors for car wash machines, including high-efficiency motors that can help reduce energy consumption and operating costs. Our motors are designed to provide reliable and consistent performance, even in harsh operating environments.

Hakkımızda

RP Techniek BV is the Netherlands sales agent of the Ever-power Group. We specialize in the production of high-quality Worm Gearbox for Rotary Brushes in Automatic Car Washing Machine. Our products are known for their reliability, efficiency, and long service life.

We have a reputation for providing the highest level of customer service and support. Our products are used by customers in Europe and North America and are popular in cities such as Amsterdam, Rotterdam, Den Haag, Utrecht, Eindhoven, Maastricht, Groningen, Leiden, Breda, Arnhem, Brussels, Antwerp, Ghent, Bruges, Dusseldorf, Cologne, Hamburg, Berlin, Frankfurt, London, Birmingham, and Manchester.

We encourage our customers to explore our products and contact us for more information. We are committed to providing the highest quality products and services at competitive prices.

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...