In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

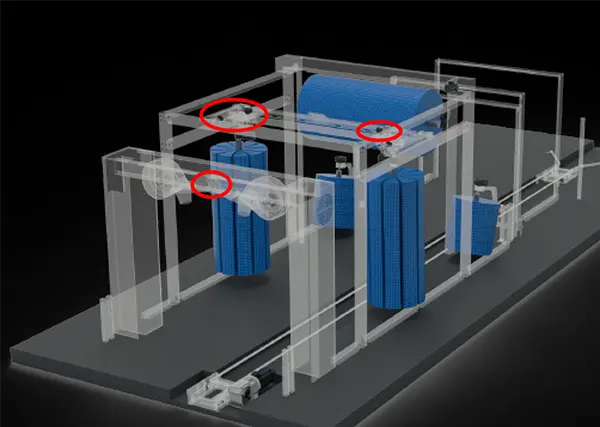

Worm Gear Reducers for Brush Shifting, Gantry Movement and Fans in Automatic Car Wash System

Worm gear reducers are an integral part of the automatic car wash system. They are used in brush shifting, gantry movement, and fans. The gearboxes are designed to reduce the speed of the electric motor while increasing the torque, making them ideal for heavy-duty applications. We provide the following MFV030, EPSRV050, EPMRV050 Series worm gearmotors for car washing machine.

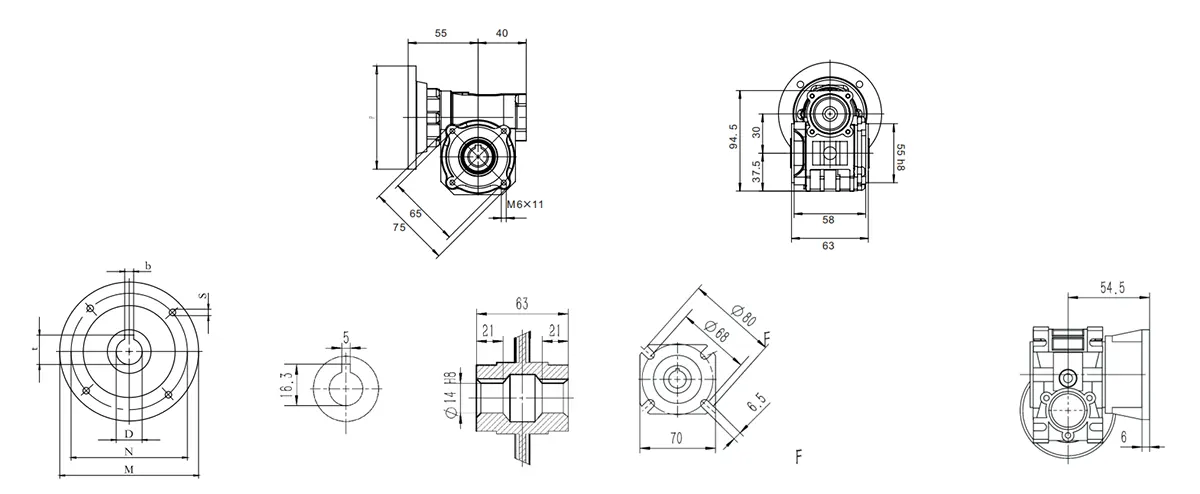

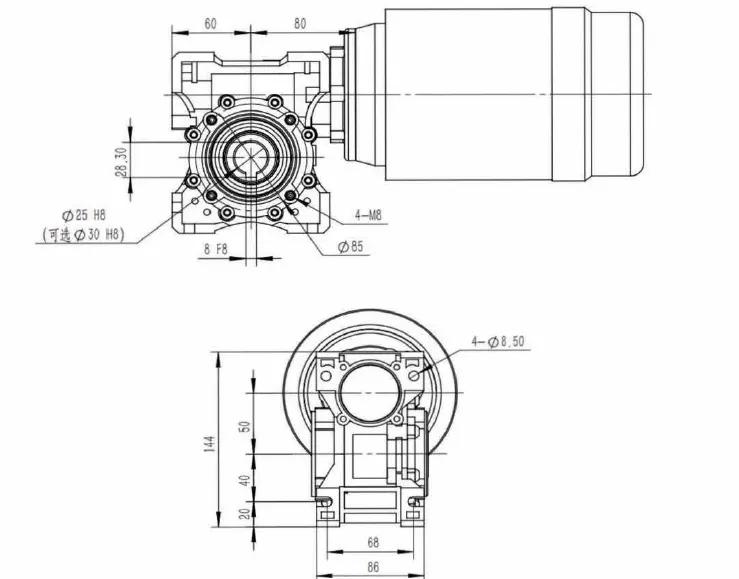

MFV030 Worm Gearbox for Automatic Car Washing Machine

The MFV Series Worm Gearbox is a versatile and compact solution, perfect for applications requiring medium to low torque, such as automatic car wash machines. With a power range of 0.06-0.18 kW, a speed ratio of 5-80, and an output speed of 15-187 r/min, this gearbox delivers an output torque of 1.8-24 Nm and handles radial forces from 597-1504 N on the output shaft. Fully interchangeable with the MRV series, the MFV030 stands out due to its smaller size, offering greater flexibility in installation while maintaining reliability, durability, and efficiency in demanding environments.

Details

| PAM | DE8 | b | t | p | M | N | S |

| IEC | |||||||

| 63B5 | 11 | 4 | 12.8 | 140 | 115 | 95 | 9 |

| 63B14 | 11 | 4 | 12.8 | 90 | 75 | 60 | 5.5 |

| 56B5 | 9 | 3 | 10.4 | 120 | 100 | 80 | 6.5 |

| 56B14 | 9 | 3 | 10.4 | 80 | 65 | 50 | 5.5 |

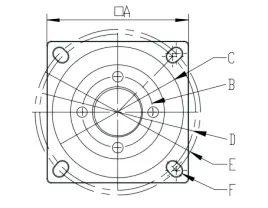

| Gearbox Size | Flange size | A | B | C | D | E | F |

| MFV030 | 60*60 | 60 | 45 | 50 | 70 | / | M5 |

| 80*80 | 80 | 45 | 60 | 90 | 94 | 6.6 | |

| 80*80 | 80 | 45 | 70 | 90 | 94 | 6.6 | |

| 85*85 | 85 | 45 | 60 | 90 | 98 | 6.6 | |

| 85*85 | 85 | 45 | 70 | 90 | 98 | 6.6 | |

| 90*90 | 90 | 45 | 83 | 102 | 106 | 6.6 | |

| 104*104 | 104 | 45 | 94 | 115 | 120 | 8.8 | |

| 104*104 | 104 | 45 | 98 | 115 | 120 | 8.8 |

Selection Table

| Type | i | n2 (min-1) |

Mn2 (Nm) |

Fr (N) |

f.s. | Motor size | P1 (kW) |

Lenth of Motor (mm) |

| MFV030 | 5 | 280 280 280 280 180 180 |

1.8 2.7 3.6 5.3 4.1 5.4 |

597 597 597 597 692 692 |

8.1 6.7 5.1 3.4 4.9 3.7 |

561-4 562-4 631-4 632-4 631-6 632-6 |

0.06 0.09 0.12 0.18 0.09 0.12 |

175 175 190 190 190 190 |

| 7.5 | 186.7 186.7 186.7 186.7 120 120 |

2.6 3.9 5.2 7.8 5.9 7.9 |

683 683 683 683 792 792 |

6.9 4.6 3.4 2.3 3.4 2.5 |

561-4 562-4 631-4 632-4 631-6 632-6 |

0.06 0.09 0.12 0.18 0.09 0.12 |

175 175 190 190 190 190 |

|

| 10 | 140 140 140 140 90 90 |

3.4 5 6.7 10 7.6 10 |

752 752 752 752 871 871 |

5.4 3.6 2.7 1.8 2.6 2.0 |

561-4 562-4 631-4 632-4 631-6 632-6 |

0.06 0.09 0.12 0.18 0.09 0.12 |

175 175 190 190 190 190 |

|

| 15 | 93.3 93.3 93.3 93.3 60 60 |

4.7 7.1 9.5 14 11 14 |

861 861 861 861 997 997 |

3.8 2.5 1.9 1.3 1.9 1.4 |

561-4 562-4 631-4 632-4 631-6 632-6 |

0.06 0.09 0.12 0.18 0.09 0.12 |

175 175 190 190 190 190 |

|

| 20 | 70 70 70 70 45 45 |

6 9 12 18 13 18 |

948 948 948 948 1098 1098 |

3.0 2.0 1.5 1.0 1.5 1.1 |

561-4 562-4 631-4 632-4 631-6 632-6 |

0.06 0.09 0.12 0.18 0.09 0.12 |

175 175 190 190 190 190 |

|

| 25 | 56 56 56 56 36 36 |

7 10 14 21 15 20 |

1021 1021 1021 1021 1183 1183 |

3.0 2.0 1.5 1.0 1.5 1.1 |

561-4 562-4 631-4 632-4 631-6 632-6 |

0.06 0.09 0.12 0.18 0.09 0.12 |

175 175 190 190 190 190 |

|

| 30 | 46.7 46.7 46.7 46.7 30 30 |

8 12 16 24 17 23 |

1085 1085 1085 1085 1257 1257 |

2.5 1.7 1.3 0.8 1.2 0.9 |

561-4 562-4 631-4 632-4 631-6 632-6 |

0.06 0.09 0.12 0.18 0.09 0.12 |

175 175 190 190 190 190 |

|

| 40 | 35 35 35 22.5 |

9.7 14 19 21 |

1194 1194 1194 1383 |

1.9 1.2 0.9 1.0 |

561-4 562-4 631-4 631-6 |

0.06 0.09 0.12 0.09 |

175 175 190 190 |

|

| 50 | 28 28 28 18 |

11 17 23 24 |

1286 1286 1286 1490 |

1.5 1.0 0.8 0.7 |

561-4 562-4 631-4 631-6 |

0.06 0.09 0.12 0.09 |

175 175 190 190 |

|

| 60 | 23.3 23.3 15 |

13 19 18 |

1367 1367 1583 |

1.3 0.9 0.9 |

561-4 562-4 562-6 |

0.06 0.09 0.06 |

175 175 175 |

|

| 80 | 17.5 | 14 | 1504 | 0.9 | 561-4 | 0.06 | 175 |

EPSRV050 Automatic Car Washer Reducer

The EPSRV050 Series Worm Gear Reducer is a robust and efficient gearbox tailored for car wash systems, with power ratings from 0.06 to 7.5 kW. Offering a speed ratio of 5-100 and an output speed of 15-280 r/min, it provides an output torque range of 1.8-800 Nm and handles radial forces between 600-10,000 N on the output shaft. Constructed with a durable stainless steel body, the EPSRV050 is highly resistant to rust and corrosion, making it an ideal choice for harsh environments exposed to water and chemicals. While similar to the EPMRV car wash gearmotor series, the EPSRV050 features a unique design that enhances its performance and longevity.

Details

| Type | Ratio | Power |

| EPSRV050 | 5 7.5 10 15 20 25 30 40 50 60 80 100 | 0.06KW 0.09KW 0.12KW 0.18KW 0.25KW 0.37KW 0.55KW 0.75KW 1.1KW 1.5KW 2.2KW 3KW 4KW |

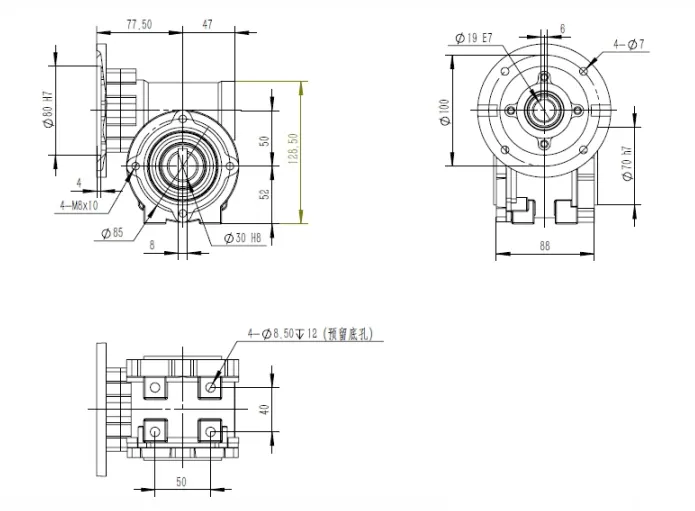

EPMRV050 Gearmotor for Automatic Car Washing Equipment

The EPMRV050 Worm Gearbox for Car Washers is designed for versatility and durability. It features modular flange options, universal mounting, and a wide ratio range to fit different needs. With an IP67 rating, it can withstand most spraying conditions. Its compact design fits easily into various equipment structures, and it uses full-synthetic oil for lubrication. The housing is made from ADC12 with powder coating, providing excellent corrosion resistance. The gearbox is sealed with a NOK oil seal for reliability, and its high-quality materials ensure strong wear resistance and long-lasting performance.

Details

| Type | Ratio | Flange | Power |

| EPMRV050 | 5 7.5 10 12 15 20 30 40 50 60 80 100 | 71B14 | 0.06KW 0.09KW 0.12KW 0.18KW 0.20KW 0.25KW 0.37KW 0.55KW 0.75KW 1.1KW 1.5KW 2.2KW 3KW 4KW 5.5KW 7.5KW |

| 80B14 |

| Type | i | n2/r/min | Mn2/Nm | Fr2/N | Motor | P1/kw | L/mm |

| EPMRV050 | 5 | 280 | 17 | 1577 | 7134 | 0.55 | 180 |

| 280 | 23 | 1577 | 8024 | 0.75 | 205 | ||

| 7.5 | 187 | 25 | 1805 | 7134 | 0.55 | 180 | |

| 187 | 34 | 1805 | 8024 | 0.75 | 205 | ||

| 10 | 140 | 22 | 1987 | 7124 | 0.37 | 180 | |

| 140 | 32 | 1987 | 7134 | 0.55 | 180 | ||

| 140 | 44 | 1987 | 8024 | 0.75 | 205 | ||

| 12 | 117 | 26 | 2016 | 7124 | 0.37 | 180 | |

| 117 | 33 | 2016 | 7134 | 0.55 | 205 | ||

| 117 | 48 | 2016 | 8024 | 0.75 | 205 | ||

| 15 | 93 | 31 | 2274 | 7124 | 0.37 | 180 | |

| 93 | 46 | 2274 | 7134 | 0.55 | 180 | ||

| 93 | 63 | 2274 | 8024 | 0.75 | 205 | ||

| 20 | 70 | 27 | 2503 | 7114 | 0.25 | 180 | |

| 70 | 40 | 2503 | 7124 | 0.37 | 180 | ||

| 70 | 59 | 2503 | 7134 | 0.55 | 180 | ||

| 70 | 81 | 2503 | 8024 | 0.75 | 205 | ||

| 25 | 56 | 32 | 2696 | 7114 | 0.25 | 180 | |

| 56 | 48 | 2696 | 7124 | 0.37 | 180 | ||

| 56 | 71 | 2696 | 7134 | 0.55 | 180 | ||

| 30 | 47 | 37 | 2865 | 7114 | 0.25 | 180 | |

| 47 | 55 | 2865 | 7124 | 0.37 | 180 | ||

| 47 | 81 | 2865 | 7134 | 0.55 | 180 | ||

| 40 | 35 | 33 | 3153 | 7114 | 0.25 | 180 | |

| 35 | 46 | 3153 | 7124 | 0.37 | 180 | ||

| 35 | 68 | 3153 | 7134 | 0.55 | 180 | ||

| 50 | 28 | 54 | 3397 | 7114 | 0.25 | 180 | |

| 28 | 72 | 3397 | 7124 | 0.37 | 180 | ||

| 28 | 80 | 3397 | 7134 | 0.55 | 180 | ||

| 52 | 27 | 55 | 3482 | 7114 | 0.25 | 180 | |

| 27 | 73 | 3482 | 7124 | 0.37 | 180 | ||

| 27 | 82 | 3482 | 7134 | 0.55 | 180 | ||

| 60 | 23 | 60 | 3610 | 7114 | 0.25 | 180 | |

| 23 | 75 | 3610 | 7124 | 0.37 | 180 | ||

| 23 | 84 | 3610 | 7134 | 0.55 | 180 | ||

| 80 | 18 | 64 | 3973 | 7114 | 0.25 | 180 | |

| 18 | 77 | 3973 | 7124 | 0.37 | 180 | ||

| 18 | 89 | 3973 | 7134 | 0.55 | 180 | ||

| 100 | 14 | 68 | 4280 | 7114 | 0.25 | 180 | |

| 14 | 79 | 4280 | 7124 | 0.37 | 180 | ||

| 14 | 93 | 4280 | 7134 | 0.55 | 180 |

Applications of Worm Gear Reducers in Automatic Car Wash System

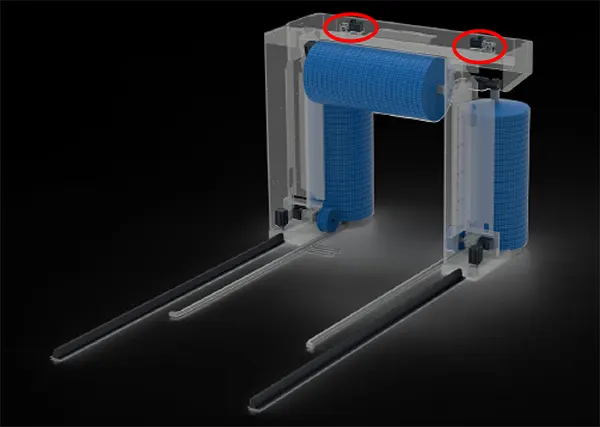

Brush Shifting

Worm gear reducers are used in brush shifting in the automatic car wash system. The brushes move horizontally and vertically to clean the car from all angles. The worm gear reducers help to control the movement of the brushes and ensure that they move smoothly and accurately.

Gantry Movement

Worm gear reducers are also used in gantry movement in the automatic car wash system. The gantry moves back and forth to wash and dry the car. The worm gear reducers help to control the movement of the gantry, ensuring that it moves smoothly and accurately.

Fans

Worm gear reducers are also used in fans in the automatic car wash system. The fans are used to dry the car after washing. The worm gear reducers help to control the speed of the fan, ensuring that it operates efficiently and quietly.

|

|

Advantages of Worm Gear Reducers in Automatic Car Wash System

- High torque capacity for heavy-duty applications

- High efficiency to reduce energy consumption

- Self-locking to prevent backdriving

- Low noise level for a quieter operation

- Low maintenance for reduced downtime

Selection of Worm Gear Reducers for Automatic Car Wash System

The selection of worm gear reducers for the automatic car wash system depends on the specific application requirements. Factors such as torque, speed, and duty cycle should be considered when selecting the appropriate gearbox. The gearbox should also be matched with the electric motor to ensure compatibility.

Maintenance of Worm Gear Reducers in Automatic Car Wash System

The maintenance of worm gear reducers in the automatic car wash system is critical to ensure their longevity and proper operation. Regular inspection and lubrication are essential to prevent wear and tear. Any signs of damage or malfunction should be addressed promptly to prevent further damage.

The installation of stainless steel worm gear reducers and motors is crucial to ensure their proper operation and longevity. The gearboxes should be installed according to the manufacturer's instructions, and the electric motor should be matched with the gearbox. Proper alignment of the motor and gearbox is essential to prevent premature wear and tear.

Common Problems and Solutions of Worm Gear Reducers

| Problem | Solution |

|---|---|

| Excessive noise | Check for proper lubrication and worn gears. Replace if necessary. |

| Overheating | Check for proper lubrication and ventilation. Reduce the load if necessary. |

| Leakage | Check for damaged seals. Replace if necessary. |

| Backlash | Check for worn gears or improper alignment. Replace or re-align if necessary. |

Motors for Car Wash Machine

Worm gear reducers and motors are two components that work together in the automatic car wash system. The motor provides the power while the gearbox reduces the speed and increases the torque. The motor and gearbox must be matched to ensure compatibility and proper operation.

We offer a range of motors for car wash machines, including AC motors, DC motors, and servo motors. Our motors are designed to work seamlessly with our worm gear reducers, providing reliable and efficient performance.

Hakkımızda

RP Techniek BV is the Netherlands sales agent of the Ever-power Group. We specialize in the production of worm gear reducers for automatic car wash systems. Our gearboxes are highly efficient and reliable, making them ideal for heavy-duty applications.

We have a strong presence in Europe and North America, with many satisfied customers in countries such as the Netherlands, Belgium, Germany, the United Kingdom, and the United States. We pride ourselves on providing the highest quality products at competitive prices, backed by exceptional customer service.

Explore our range of products and contact us to learn more about how we can help you with your automatic car wash system needs.

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...