In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

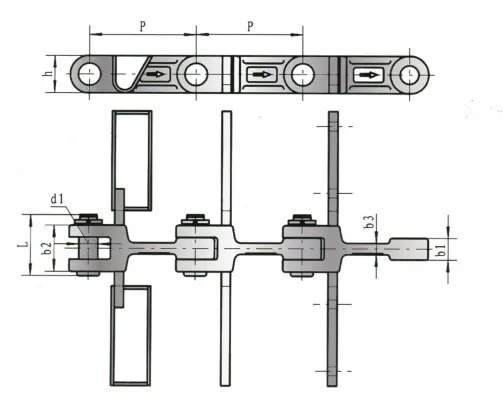

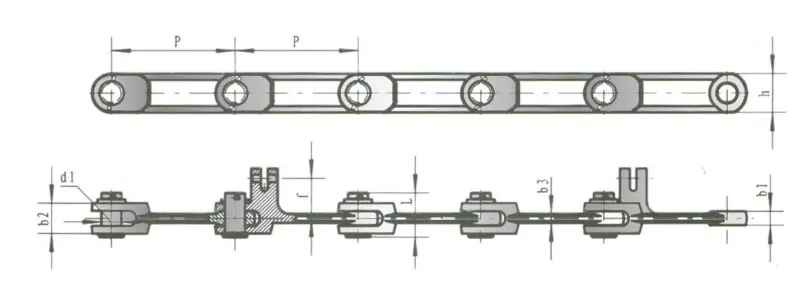

Details of Stainless Steel Metallurgical Scraper Chain

| P | d1(mm) | b1(mm) | b2(mm) | b3(mm) | f(mm) | L(mm) |

| 142 | 25 | 19 | 43 | 12.2 | 35 | 69 |

| P | d1(mm) | b1(mm) | b2(mm) | b3(mm) | L(mm) |

| 142 | 25 | 29 | 62 | 15 | 82 |

| P | d1(mm) | h(mm) | b1(mm) | b2(mm) | b3(mm) | f(mm) | L(mm) |

| 200 | 25 | 50 | 24 | 58 | 17 | 38 | 75 |

| P | d1(mm) | h(mm) | b1(mm) | b2(mm) | b3(mm) | f(mm) | L(mm) |

| 200 | 32 | 64 | 23 | 50 | 15 | 66 | 69 |

giriiş

The Stainless Steel Metallurgical Scraper Chain is a high-quality and durable chain specifically designed for use in metallurgical applications. With its exceptional strength and corrosion resistance, it ensures reliable and efficient operation in harsh environments.

Metallurgical Scraper Chain Features

Enhanced Material Composition

Our Stainless Steel Metallurgical Scraper Chain is crafted using a unique blend of stainless steel alloys, carefully selected to provide superior mechanical properties and resistance to corrosion. This advanced material composition guarantees exceptional performance and longevity, even when exposed to extreme temperatures and corrosive substances.

Precision Engineering

Each link in our scraper chain is meticulously engineered to ensure precise fit and smooth operation. The intricate design incorporates specialized features, such as reinforced pins and bushings, to withstand heavy loads and resist wear. This level of precision guarantees optimal performance and minimizes maintenance requirements.

High Load Capacity

The Stainless Steel Metallurgical Scraper Chain is engineered to handle heavy loads with ease. Its robust construction and advanced metallurgy provide exceptional strength, allowing it to withstand the demanding conditions of metallurgical operations. Whether it is carrying hot molten metal or abrasive materials, this chain delivers reliable and consistent performance.

Corrosion Resistance

Corrosion is a common challenge in metallurgical environments. Our Stainless Steel Metallurgical Scraper Chain is specifically designed to combat this issue. The stainless steel alloys used in its construction offer excellent resistance to corrosion, ensuring long-term durability and minimizing the risk of chain failure. This makes it an ideal choice for applications where exposure to corrosive substances is unavoidable.

Low Maintenance

With its superior design and high-quality materials, our Stainless Steel Metallurgical Scraper Chain requires minimal maintenance. The precision-engineered links reduce friction and wear, extending the chain's lifespan and reducing the need for frequent replacements. This not only saves time and effort but also reduces downtime and production costs.

Versatile Applications

The Stainless Steel Metallurgical Scraper Chain finds extensive use in various metallurgical applications. Whether it is in steel mills, foundries, or other metal processing facilities, this chain excels in transporting hot metal, slag, or other abrasive materials. Its versatility, combined with its durability and reliability, makes it an indispensable component in the metallurgical industry.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV is the Dutch sales agent of Ever-power Group. We are proud to represent this renowned company in the Netherlands. Our specialty lies in the Stainless Steel Metallurgical Scraper Chain, which showcases our unique selling points and highlights the superior quality and service we offer. With our extensive expertise and state-of-the-art production capabilities, we ensure that our chains meet the highest standards in the industry.

In addition to the Stainless Steel Metallurgical Scraper Chain, we also offer a wide range of other stainless steel roller chains. Our diverse selection caters to various needs and requirements, ensuring that you will find the perfect chain for your specific application. We prioritize customer satisfaction and strive to exceed expectations with every product we deliver.

Trust RP Techniek BV and Ever-power Group for all your stainless steel chain needs. Contact us today to learn more about our products and how we can assist you.

How to Select Suitable Sprockets?

When it comes to selecting suitable sprockets for your Stainless Steel Metallurgical Scraper Chain, there are a few factors to consider. Firstly, you need to determine the pitch diameter and the number of teeth required for your specific application. This will depend on the speed and torque requirements of your machinery.

Secondly, it is important to choose the right material for your sprockets. Stainless Steel sprockets offer excellent corrosion resistance and durability, making them ideal for industrial applications. Our company provides a wide range of sprockets made from different materials to cater to various customer needs.

Furthermore, you should consider the type of hub attachment required for your sprockets. We offer different hub styles such as plain bore, tapered bore, and keyway options to ensure compatibility with your equipment.

Lastly, for optimal performance and longevity, regular maintenance and lubrication of your sprockets are essential. Our team can provide guidance on proper maintenance practices to ensure your sprockets operate smoothly.

Ek Bilgiler

| Edited by | Zqq. |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...