In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

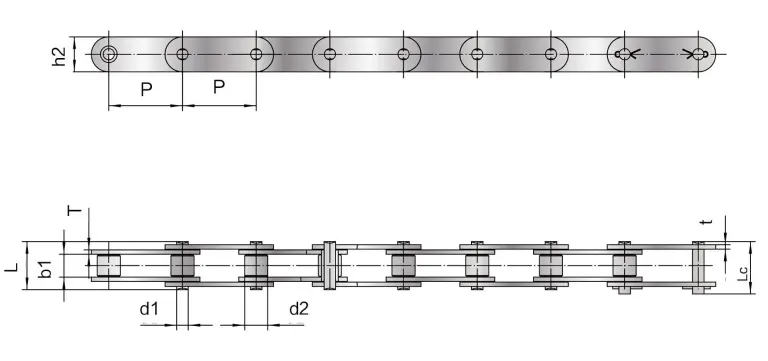

Dimensions of SS500R Stainless Steel Lumber Conveyor Chain

Here are the parameters of the SS500R Stainless Steel Lumber Conveyor Chain:

| Chain No. | Pitch | Roller Çap |

Width Between Inner Plates |

Pin Çap |

Pin Length | Plate Dimensions | UItimate Tensile Strength |

Average Tensile Strength |

Ağırlık Per Meter |

||

| P | d2 | b1 | d1 | L | Lc | h2 | T/t | Q | Q0 | q | |

| max | max | max | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | KN | Kg/m | |

| SS81X | 66.27 | 23 | 27 | 11.1 | 49 | 53.5 | 28.5 | 4 | 74.69 | 90.23 | 3.78 |

| SS81XH | 66.27 | 23 | 27.78 | 11.1 | 60.7 | 65.1 | 31.35 | 7.94/5.551 | 106.33 | 122.99 | 5.88 |

| SS81XHE | 66.27 | 22.2 | 27 | 11.1 | 59.5 | 63 | 28.5 | 6.3 | 58.31 | 62.37 | 5.09 |

| SS81XF14 | 66.27 | 23 | 27 | 11.1 | 50.8 | 53.8 | 28.7 | 4 | 59.85 | 63.98 | 3.78 |

| SS81XHH | 66.27 | 23 | 27.78 | 11.1 | 65.6 | 70 | 31.35 | 7.94 | 133.77 | 148.82 | 6.7 |

| SS81XHS | 66.27 | 23 | 27 | 11.1 | 63.6 | 68 | 31.8 | 7.6 | 106.4 | 124.04 | 6.55 |

| SS500R | 50 | 25.4 | 25.4 | 14.63 | 52 | 56.4 | 40 | 5 | 70 | 80.15 | 7.13 |

| SS441.100R | 100 | 25.4 | 25.4 | 14.63 | 52 | 56.4 | 40 | 5 | 70 | 80.15 | 5.15 |

giriiş

The SS500R Stainless Steel Lumber Conveyor Chain is a robust and durable chain designed specifically for the lumber industry. Its high-quality stainless steel construction ensures long-lasting performance even in harsh environments. With its superior strength and reliability, this conveyor chain is an ideal solution for transporting lumber efficiently and safely.

Features

1. Corrosion Resistance

The SS500R chain is made of premium stainless steel material that offers exceptional resistance against corrosion. This feature makes it perfect for applications where exposure to moisture, chemicals, or extreme temperatures is common.

2. High Load Capacity

Equipped with specially designed rollers and pins, this conveyor chain can handle heavy loads with ease. Its high load capacity ensures smooth and efficient operation, minimizing downtime and maximizing productivity.

3. Low Maintenance

The SS500R chain requires minimal maintenance, thanks to its self-lubricating capability. This reduces the need for frequent lubrication, saving both time and money. Additionally, its durable construction minimizes the risk of chain elongation, further reducing maintenance requirements.

4. Precision Engineering

Each SS500R chain is precision-engineered to ensure optimal performance and reliability. The chain's components are manufactured to tight tolerances, resulting in smooth and efficient operation. This precision engineering also enhances the chain's durability and extends its service life.

5. Versatility

The SS500R chain is designed to fit a wide range of conveyor systems, making it a versatile choice for various lumber handling applications. Its compatibility with different equipment and configurations allows for easy integration with existing setups, minimizing the need for costly modifications.

Conclusion

The SS500R Stainless Steel Lumber Conveyor Chain is the perfect solution for the lumber industry's demanding transportation needs. With its corrosion resistance, high load capacity, low maintenance requirements, precision engineering, and versatility, this chain offers outstanding performance and reliability. Invest in the SS500R chain and experience the benefits of a durable and efficient conveyor system for your lumber handling operations.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. With our extensive experience and technical expertise, we are proud to offer the SS500R Stainless Steel Lumber Conveyor Chain as one of our unique selling points.

Our stainless steel roller chains are renowned for their exceptional quality and durability. Each chain is meticulously crafted using high-grade stainless steel, ensuring long-lasting performance even in demanding industrial environments. Our commitment to excellence is reflected in every link of our chains.

Not only do we prioritize product quality, but we also provide outstanding customer service. Our dedicated team of professionals is readily available to assist you with any inquiries or support you may need. We strive to build long-term relationships with our customers by delivering prompt and personalized attention.

Furthermore, our strong production capabilities enable us to meet the diverse needs of our clients. In addition to the SS500R Stainless Steel Lumber Conveyor Chain, we offer a wide range of other stainless steel roller chains for various applications. Whether you require chains for food processing, automotive, or industrial machinery, we have the perfect solution for you.

Sprockets for Sale

When it comes to finding the right sprockets for your SS500R Stainless Steel Lumber Conveyor Chain, it's important to consider the size and tooth count that will provide the desired speed and torque. At our company, we offer a wide range of sprockets to fit any conveyor chain needs.

Our sprockets are made with high-quality materials, ensuring durability and longevity, even in demanding industrial environments. We offer various sizes and tooth counts to match your specific conveyor chain, ensuring maximum efficiency and performance.

Whether you need a standard roller chain sprocket or a custom-designed sprocket for your unique application, we have you covered. Our team of experts can help you choose the right sprocket for your needs and even provide custom manufacturing services for specific requirements.

Contact us today to learn more about our sprockets for sale and how we can help you find the perfect fit for your conveyor chain.

Ek Bilgiler

| Editor | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...