In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications

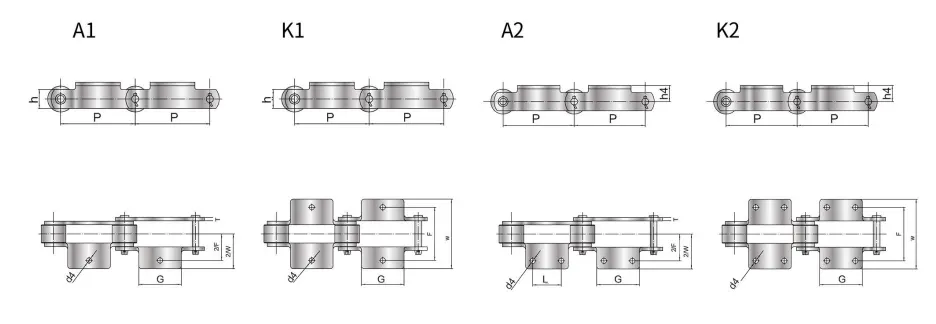

This RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF650 has the following parameters:

| Chain No. | Roller Type | Pitch (P) |

h4 | 2/F | F | 2W | W | L | T | d4 | Bolt Dimension |

Weight of SA2 att.(KG) |

|

| RF0375 | R/F/S | 75 | 20 | 30 | 60 | 46 | 92 | 30 | 55 | 3.2 | 10 | M8 | 0.05 |

| RF03100 | R/F/S | 100 | 20 | 30 | 60 | 46 | 92 | 40 | 65 | 3.2 | 10 | M8 | 0.06 |

| RF430 | R/S | 101.6 | 22 | 40 | 80 | 54 | 108 | 40 | 70 | 4.8(5.0) | 12 | M10 | 0.11 |

| RF05075 | S | 75 | 22 | 35 | 70 | 47 | 94 | 30 | 55 | 4.5 | 10 | M8 | 0.07 |

| RF05100 | R/F/S | 100 | 22 | 35 | 70 | 47 | 94 | 40 | 65 | 4.5 | 10 | M8 | 0.08 |

| RF05150 | R/F/S | 150 | 22 | 35 | 70 | 47 | 94 | 60 | 85 | 4.5 | 10 | M8 | 0.1 |

| RF204 | S | 66.27 | 24 | 45 | 90 | 59 | 118 | - | 35 | 6.3(6.0) | 12 | M10 | 0.08 |

| RF450 | R/F/S/M | 101.6 | 28 | 50 | 100 | 64 | 128 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.18 |

| RF08150 | R/F/S/M | 150 | 28 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF650 | R/F/S/M | 152.4 | 32 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF10100 | R/S/M | 100 | 28 | 50 | 100 | 65 | 130 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.16 |

| RF10150 | R/F/S/M | 150 | 28 | 50 | 100 | 65 | 130 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.2 |

| RF214 | R/S/M | 101.6 | 35 | 55 | 110 | 73 | 146 | 40 | 80 | 7.9 | 15 | M12 | 0.28 |

| RF205 | S | 78.11 | 35 | 60 | 120 | 75 | 150 | 30 | 65 | 7.9 | 12 | M10 | 0.23 |

| RF6205 | R/F/S/M | 152.4 | 38 | 60 | 120 | 79 | 158 | 60 | 100 | 7.9 | 15 | M12 | 0.37 |

| RF12200 | R/F/S/M | 200 | 38 | 60 | 120 | 79 | 158 | 80 | 120 | 7.9 | 15 | M12 | 0.45 |

| RF12250 | R/F/S/M | 250 | 38 | 60 | 120 | 79 | 158 | 125 | 170 | 7.9 | 15 | M12 | 0.62 |

| RF212 | R/S/M | 152.4 | 45 | 65 | 130 | 83 | 166 | 60 | 100 | 9.5(10.0) | 15 | M12 | 0.49 |

| RF17200 | R/F/S/M | 200 | 45 | 75 | 150 | 98 | 196 | 80 | 120 | 9.5(10.0) | 15 | M12 | 0.66 |

| RF17250 | R/F/S/M | 250 | 45 | 75 | 150 | 98 | 125 | 125 | 170 | 9.5(10.0) | 15 | M12 | 0.86 |

giriiş

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF650 is a highly versatile and efficient conveyor chain designed for various industrial applications. With its unique design and advanced features, this conveyor chain offers exceptional performance and reliability, making it an ideal choice for material handling systems.

Key Features

1. High Strength and Durability

2. Precision Engineering for Smooth Operation

3. Enhanced Load Capacity

4. Easy Installation and Maintenance

5. Corrosion and Abrasion Resistance

Uygulamalar

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF650 finds wide applications in various industries, including:

1. Automotive

2. Food Processing

3. Packaging

4. Material Handling

5. Pharmaceutical

Design and Construction

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF650 is meticulously designed and constructed using high-quality materials to ensure exceptional performance and longevity. Its key design elements include:

1. Solid Rollers for Smooth and Efficient Movement

2. Robust Side Plates for Increased Strength

3. Precise Pitch Control for Reliable Operation

4. Flexible Attachment Points for Versatile Applications

5. Secure Pin and Bushing System for Enhanced Load Bearing Capacity

Benefits

1. Improved Efficiency and Productivity

2. Reduced Downtime and Maintenance Costs

3. Enhanced Safety and Reliability

4. Increased Product Handling Flexibility

5. Cost-effective Solution for Material Handling Needs

Conclusion

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF650 is the perfect choice for industries looking for a reliable and efficient conveyor chain solution. With its exceptional features, durability, and versatility, this conveyor chain ensures smooth and seamless material handling operations, leading to improved productivity and overall operational efficiency. Invest in the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF650 and experience the difference it can make in your industrial applications.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV, as the Netherlands sales agent of Ever-power Group, offers a wide range of stainless steel roller chains. Our RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF650 stands out with its unique selling points, emphasizing the exceptional product quality and services we provide. With our strong production capabilities, we ensure that our stainless steel roller chains meet the highest standards in the industry.

In addition to the RF650 chain, we also offer various other types of stainless steel roller chains. Our extensive selection caters to diverse applications, providing solutions for different industries. Whether you require chains for high-speed operations or heavy-duty applications, we have the right product to meet your specific needs.

With our commitment to excellence and customer satisfaction, RP Techniek BV guarantees reliable and durable stainless steel roller chains that deliver optimal performance. Trust us for all your chain requirements, and experience the quality and service that sets us apart from the competition.

[](https://netherlandsdrive.com/wp-content/uploads/2024/09/manufacturer-1.webp)

Sprockets for Sale

When it comes to RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF650, finding the right sprocket is crucial for smooth and efficient operation. At our company, we offer a wide variety of sprockets that are compatible with this type of conveyor chain.

Our selection of sprockets for the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF650 includes a range of sizes and materials to suit various applications. We have sprockets made from high-quality steel, cast iron, and other durable materials to ensure long-lasting performance.

Depending on the specific requirements of your conveyor system, we can provide you with the appropriate sprocket to ensure optimal performance. Our experienced technicians can help you select the right sprocket for your needs and provide you with any additional information you require.

At our company, we understand the importance of having reliable and high-quality components for your conveyor system. That's why we offer a comprehensive range of sprockets and other conveyor parts to meet all your needs.

Ek Bilgiler

| Editor | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...