In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Planetary Gearboxes for Wind Turbine Details

| Specification Parameter | Details |

|---|---|

| Output Torque Range | 1000 - 80000 N.m |

| Gear Ratio | i = 300 - 2000 |

| Support Method | Slew Support (Flange Mounted) |

| Electric Brake | DC and AC Types |

| Output Shaft | Splined Shaft or with Integral Pinion; Output Shaft Supported by Heavy-duty Bearings |

| Applicable Motor | IEC Electric Motor |

Wind Turbine Gearbox Types

When considering gearbox types for wind turbines, planetary gearboxes are noted for their efficiency and robustness. Unlike helical or spur gear systems, planetary designs distribute loads over multiple gears, which decreases wear and prolongs service life. This makes them particularly suitable for wind turbines, where stable power output is essential.

In wind power setups, yaw drive gearboxes are crucial for aligning the cabin with the wind direction, ensuring optimal energy extraction. Additionally, the variable-pitch drive gearbox modifies the angle of the turbine blades for speed adjustment and protection against high winds. Both systems depend on robust planetary designs to endure dynamic loads and challenging environmental conditions.

Our range of planetary transmissions can be customized to accommodate various turbine sizes and operational requirements, including yaw and pitch systems as well as the main drive train. This adaptability offers procurement managers a dependable, high-performance solution for every component in wind power generation.

| Type | Nominal Output Torque (N.m ) | Peak Static Output Torque (N.m ) | Ratio (i) |

| RP700L | 1000 | 2000 | 297–2153 |

| RP701L | 2000 | 4000 | 297–2153 |

| RP703AL | 2500 | 5000 | 278–1866 |

| RP705AL | 5000 | 10000 | 278–1866 |

| RP706BL4 | 8000 | 15000 | 203–2045 |

| RP707AL4 | 12000 | 25000 | 278–1856 |

| RP709AL4 | 18000 | 30000 | 278–1856 |

| RP711BL4 | 35000 | 80000 | 256–1606 |

| RP710L4 | 25000 | 50000 | 329–1420 |

| RP711L4 | 35000 | 80000 | 256–1606 |

| RP713L4 | 50000 | 100000 | 250–1748 |

| RP715L4 | 80000 | 140000 | 269–1390 |

Wind Turbine Gearbox Design

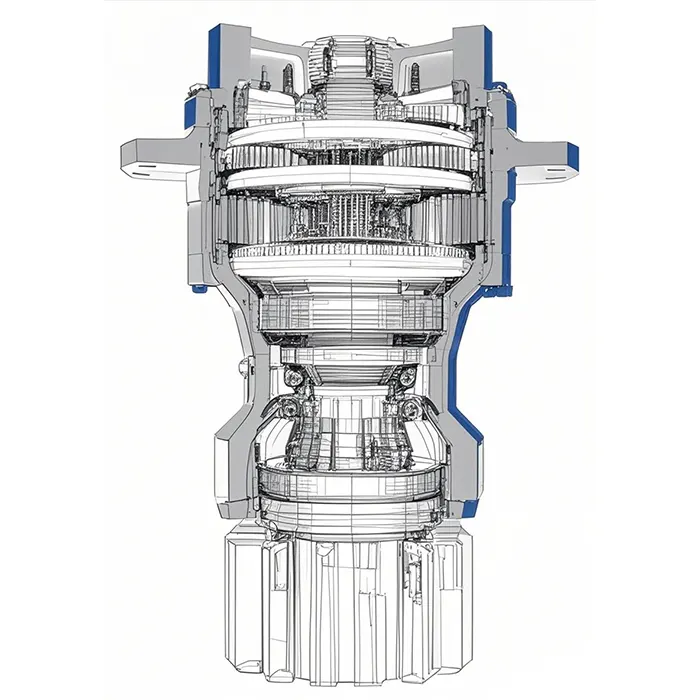

Our wind turbine planetary gearboxes are meticulously designed with both precision and adaptability in focus. The structure features a compact design where planetary gears rotate around a central sun gear, optimizing space while maximizing torque. Constructed using advanced materials designed to endure harsh environmental conditions, our gearboxes are the preferred choice for procurement teams aiming to minimize downtime and enhance system performance.

Wind Turbine Planetary Gearbox Components

The components of our planetary gearbox systems for wind turbines include high-quality planetary gears, solar gears, rings, and robust bearings. Each component has been thoughtfully designed to allow seamless integration and durability, ensuring the efficient functioning of the gearbox under varying wind loads.

Purpose of Planetary Gearbox in Wind Turbine

The blades of the wind turbine are activated by wind energy, transferring torque to the gearbox via the main shaft. The gearbox incrementally adjusts the speed through the various gear levels to fulfill the generator's speed requirements, while simultaneously transmitting torque to the generator to convert mechanical energy into electrical energy.

Wind Turbine Gearbox Maintenance

Standardized installation and commissioning

1. Install in strict accordance with the installation process requirements to ensure that shaft alignment, installation clearance, etc., meet the standards.

2. Develop a scientifically sound commissioning plan, apply load gradually, and avoid impacts on the wind turbine gearbox.

Strengthen operation and maintenance

1. Establish a reasonable operational strategy to prevent long-term overload operation of wind turbines.

2. Regularly inspect and replace lubricating oil to ensure that the quality and fill level meet the requirements.

3. Conduct daily inspections of the gearboxes in turbines to promptly identify and address abnormal conditions.

4. Perform comprehensive maintenance and care on gearboxes, including cleaning, inspection, and replacement of worn parts.

Improve the operating environment

1. Implement effective protective measures, such as installing wind and sand protection devices and enhancing ventilation and heat dissipation, to improve the operating environment of the gearbox in a wind turbine.

2. Regularly clean and protect the gearbox to prevent dust, moisture, and other contaminants from entering.

Wind Turbine Gearbox Lubrication System

The lubrication system in wind turbine gearboxes comprises an oil pump system and a lubricating oil pathway. The oil pump system is tasked with drawing lubricating oil from the storage tank and directing it to the turbine gearbox for lubrication; the lubricating oil pathway distributes the oil to various components. Typically, either a circulating lubrication system or a static pressure lubrication system is utilized. The circulating system offers simplicity and low cost but may compromise lubrication effectiveness; conversely, the static pressure system is more effective and quieter but presents complexity and higher costs.

Why Choose Us

As one of the Netherlands' foremost wind turbine gearbox manufacturers, we blend innovation with industry expertise to deliver outstanding planetary gearboxes for wind turbines. Our planetary gearboxes are rigorously tested to meet international standards, ensuring dependable solutions for procurement teams. Collaborate with us to obtain gearboxes that enhance the efficiency and lifespan of your wind turbines while receiving exceptional customer support.

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...