In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

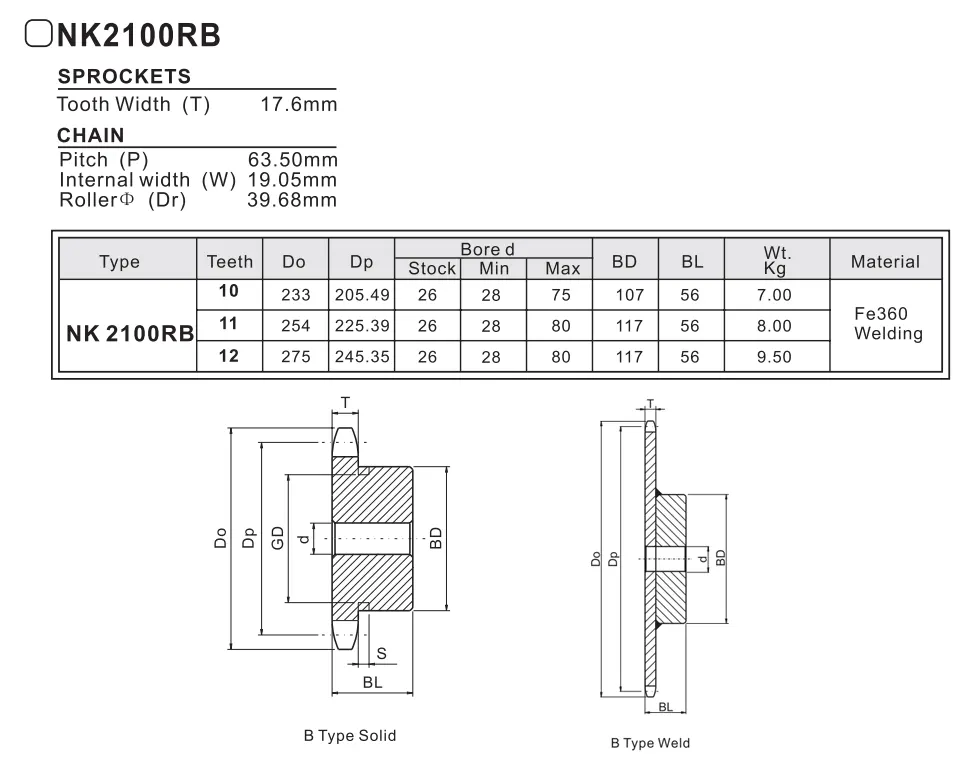

NK2100RB Double Pitch Sprocket

The NK2100RB Double Pitch Sprocket is designed for efficient power transmission in various applications. With its robust construction and precise engineering, it ensures optimal performance and durability, making it an ideal choice for industrial and mechanical systems requiring reliable operation.

Specifications of NK2100RB Double Pitch Sprocket

The NK2100RB Double Pitch Sprocket is a crucial component in power transmission systems, specifically designed for use with double pitch roller chains. These chains are characterized by a longer pitch in comparison to standard roller chains, enabling them to handle various applications effectively. This type of sprocket is widely utilized in systems such as conveyor lines, packaging machinery, and a range of industrial equipment, showcasing its versatility and reliability in different environments.

The defining feature of the double pitch sprocket is its pitch, which is twice that of a conventional roller chain. It incorporates two sets of teeth that are positioned farther apart than those on standard sprockets. This design allows for proper engagement with the longer pitch of the double pitch roller chain, ensuring efficient power transmission while reducing wear and tear.

The fundamental structure of a double pitch sprocket includes two sets of teeth that are spaced further apart compared to those of a standard sprocket. Additionally, it features a center hub that is designed to fit securely onto a shaft or spindle, facilitating easy installation in various machinery setups.

Main Features

- Greater Pitch: The double pitch sprocket boasts a larger pitch than standard sprockets, which accommodates the use of a larger roller chain, enhancing overall performance.

- Higher Load Capacity: With a higher load capacity than its standard counterparts, this sprocket is ideal for heavy-duty applications, ensuring reliability even under significant stress.

- Smooth Operation: Engineered for smooth and quiet operation, this sprocket is particularly suited for applications where noise sensitivity is a concern, providing an optimal user experience.

Material Selection

Double pitch sprockets can be manufactured from a variety of materials, each offering unique properties suitable for different applications. The choice of material significantly impacts the performance and durability of the sprocket, ensuring it meets the specific needs of various industries.

- Carbon Steel: Widely used for double pitch sprockets, carbon steel is known for its strength, durability, and cost-effectiveness, making it an ideal choice for general applications.

- Alloy Steel: This high-strength material is particularly suited for demanding heavy-duty applications, providing enhanced performance under extreme conditions.

- Stainless Steel: Renowned for its corrosion resistance, stainless steel is an excellent option for food processing and other applications that require high levels of cleanliness and hygiene.

Manufacturing Process

The manufacturing process for double pitch sprockets involves several essential steps that contribute to the quality and reliability of the final product:

- Raw Material Preparation: The process begins with the careful selection and preparation of the appropriate raw materials for manufacturing.

- Forging or Casting: The sprocket is shaped either through forging or casting methods, depending on the design specifications.

- Machining: Precision machining is conducted to achieve the required dimensions and tolerances for optimal performance.

- Tooth Rolling: The teeth are rolled onto the sprocket using specialized machines to ensure accuracy and consistency.

- Heat Treatment: A heat treatment process is applied to enhance the strength and durability of the sprocket, ensuring it can withstand operational stresses.

- Yüzey İşlem: A protective coating is applied to prevent corrosion and extend the lifespan of the sprocket.

- Quality Control: The final product undergoes thorough inspection to ensure it meets all specified standards and requirements.

Customization Services

We provide a variety of customization services for our double pitch sprockets, allowing clients to tailor their products to specific needs. Our customization options include material selection, tooth profile design, and bore and keyway configurations to ensure a perfect fit for various machinery setups.

- Material Selection: Choose from an array of materials, including carbon steel, alloy steel, and stainless steel, to match your specific requirements.

- Tooth Profile Design: We offer the ability to create custom tooth profiles designed according to your specifications and operational needs.

- Bore and Keyway Options: A range of bore and keyway choices are available to ensure compatibility with your machinery, enhancing overall efficiency.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the sales agent for Ever-power Group in the Netherlands, specializing in high-quality sprockets and chain-related products. Among our featured offerings is the NK2100RB Double Pitch Sprocket, engineered to deliver superior performance and durability for various industrial applications. Our sprockets are designed to meet stringent standards, guaranteeing reliability and efficiency in your operations.

In addition to our standard offerings, we also provide custom solutions tailored to the unique specifications of our clients. This capability allows us to manufacture non-standard sprockets based on your design or sample requests. We encourage customers to reach out for custom designs that meet their specific needs.

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...