In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

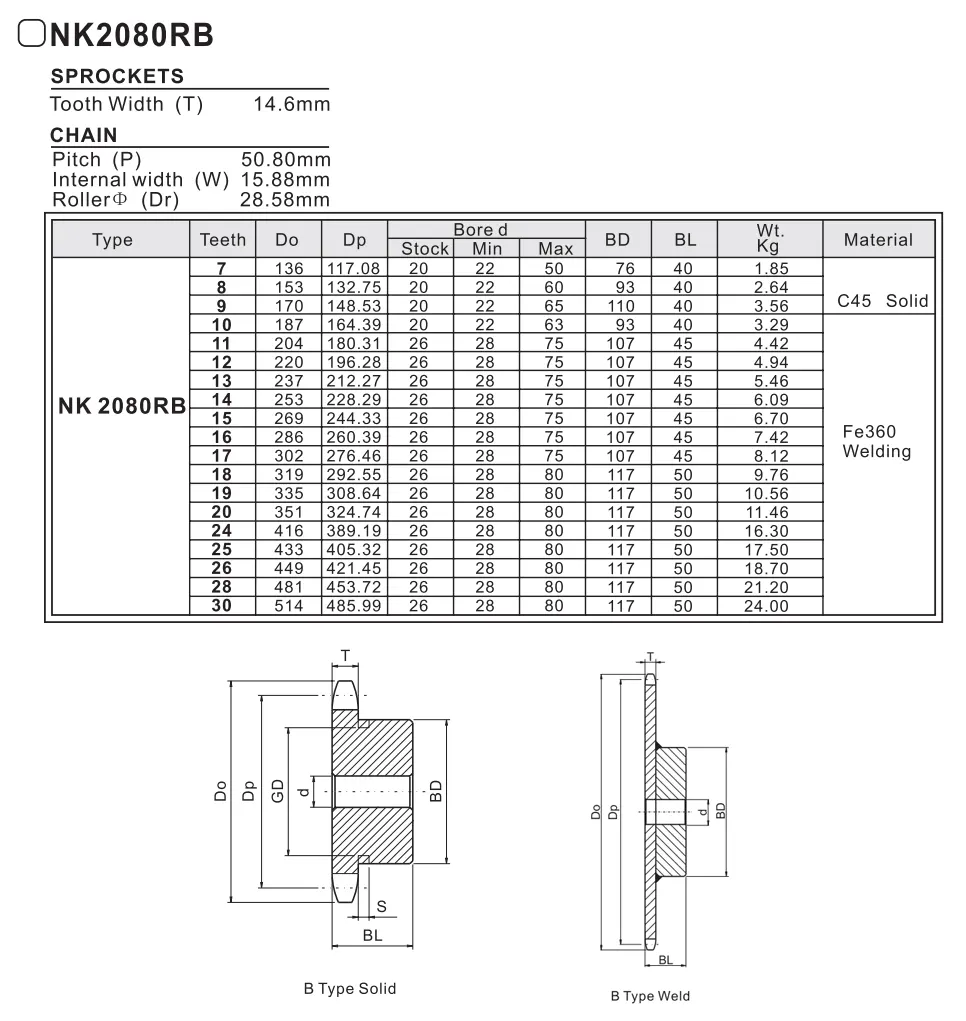

NK2080RB Double Pitch Sprocket

The NK2080RB Double Pitch Sprocket is designed for high-performance applications, featuring robust construction and precision engineering. Ideal for conveyor systems and machinery, this sprocket ensures smooth operation and enhanced durability, making it a reliable choice for various industrial settings.

Specifications of NK2080RB Double Pitch Sprocket

NK2080RB Double Pitch Sprocket represents a versatile type of sprocket frequently utilized in transmission systems. Its design features a double pitch, signifying that the distance between the teeth is twice that of a standard sprocket. This distinctive design is ideal for specialized applications that necessitate a larger pitch diameter, thereby enhancing functionality and compatibility with various machinery.

Definition and Basic Structure

- A double pitch sprocket is characterized by a larger tooth pitch when compared to standard sprockets. This design makes it particularly valuable in conveyor systems and other applications where a longer chain pitch is essential for effective operation and efficiency.

- The fundamental structure of a double pitch sprocket comprises teeth, a hub, and a bore. The teeth are crafted to engage with the chain effectively, while the hub serves as the support connecting the sprocket to the shaft. The bore facilitates the mounting of the sprocket onto the shaft, ensuring stability and performance.

Main Features

- Greater tooth spacing: The design enables increased spacing between the teeth, minimizing the likelihood of chain jamming and enhancing overall operational performance across different conditions.

- Higher load capacity: The structural design of the double pitch sprocket allows it to endure greater loads, facilitating efficient operation even in heavy-duty scenarios.

- Smooth operation: The well-defined tooth profile, coupled with high-quality manufacturing practices, guarantees a smooth and reliable operation, which helps in reducing noise and vibrations during use.

Material Selection

Double pitch sprockets can be manufactured from a variety of materials such as carbon steel, alloy steel, and stainless steel. Each type of material possesses unique characteristics, making them suitable for different applications based on environmental conditions and performance requirements.

Manufacturing Process

- Raw material preparation: The selected material undergoes processing and preparation steps to ensure it is ready for manufacturing.

- Forging or casting: Depending on the desired strength and production method, the sprocket can be either forged or cast.

- Machining: The sprocket is subjected to machining processes that allow for precise dimensions and smooth surface finishes.

- Tooth cutting: Specialized equipment is utilized to cut the teeth, ensuring precise profiles and accurate spacing.

- Heat treatment: This process enhances the sprocket's hardness and overall durability.

- Surface treatment: The surface of the sprocket is treated to prevent corrosion and to improve the overall aesthetic appearance.

- Quality testing: The completed sprocket goes through stringent quality testing to confirm it adheres to the established standards and specifications.

Customization Services

- Material selection: We provide a diverse range of materials, enabling customers to choose the most appropriate one for their specific application requirements.

- Tooth profile design: Our experts can assist in developing custom tooth profiles tailored to meet particular specifications, optimizing both performance and durability.

- Bore diameter and keyway: We offer customization options for bore diameter and keyway design, ensuring a precise fit and proper alignment with the shaft.

Sprockets Supplier in Netherlands

RP Techniek BV is the sales agent for the Ever-power Group in the Netherlands, focusing on high-quality industrial components. A key product in our lineup is the NK2080RB Double Pitch Sprocket, designed for enhanced efficiency and durability in a variety of applications. Our sprockets are manufactured with advanced technology and materials to meet the demanding needs of our clientele.

Moreover, we provide customized solutions that cater to individual client requirements. Customers are encouraged to submit their designs or samples for tailored sprocket production, ensuring a perfect fit for operational demands.

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...