The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Magnetic Worm Gear

The Magnetic Worm Gear is an advanced mechanical component designed for efficient power transmission. Made from high-quality materials such as aluminum and stainless steel, it ensures durability and reliability. The Magnetic Worm Gear effectively reduces speed while increasing torque, making it ideal for various applications in robotics and machinery.

Details of Magnetic Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 10:1 |

| Torque Rating | 50 Nm |

| Input Speed | 1000 RPM |

| Output Speed | 100 RPM |

| Efficiency | 85% |

| Ağırlık | 2.5 kg |

| Material | Aluminum Alloy |

Features of Magnetic Worm Gear

- High Efficiency: The Magnetic Worm Gear offers superior efficiency due to its unique design, which minimizes energy loss during operation. This results in smoother performance and reduced heat generation.

- Compact Design: Its compact design allows for easy integration into various applications, making it an ideal choice for space-constrained environments.

- Durability: Built with high-quality materials, the Magnetic Worm Gear is designed to withstand wear and tear, ensuring longevity and reliability in demanding conditions.

- Low Noise Operation: The gear's design enables quieter operation, making it suitable for applications where noise reduction is essential.

Applications of Magnetic Worm Gear in Modern Machinery

The Magnetic Worm Gear is an essential component in various industrial applications due to its unique design and functionality. This innovative gear system offers excellent torque transmission and compactness, making it ideal for use in robotics, conveyor systems, and precision machinery. The Magnetic Worm Gear ensures smooth operation and effective power transfer, enhancing overall system efficiency. Its magnetic properties also allow for improved control and stability in dynamic environments. By incorporating this advanced gear technology, industries can achieve greater performance and reliability in their machinery.

Manufacturing Process of Magnetic Worm Gear

- Material Selection: The initial step in the manufacturing process of Magnetic Worm Gear involves selecting high-quality materials that provide durability and efficiency. Common materials include steel and aluminum, chosen for their strength and resistance to wear. The goal is to ensure that the Magnetic Worm Gear can withstand heavy loads and operate smoothly. The quality of the raw material directly impacts the performance and longevity of the gear, making this phase critical.

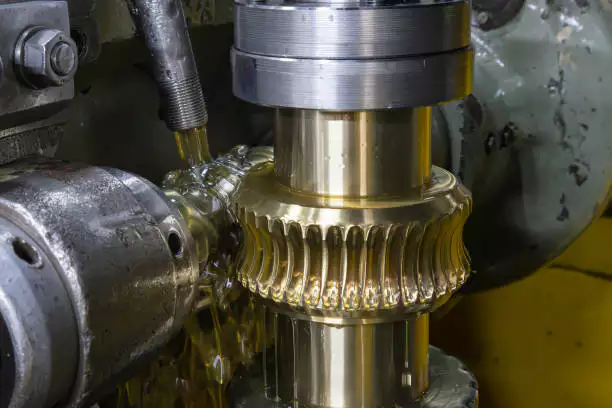

- Precision Machining: After material selection, the Magnetic Worm Gear undergoes precision machining. This process includes cutting, shaping, and finishing the gear to meet specified tolerances. Advanced CNC machines are typically used for this task, ensuring that each gear is manufactured with high precision. This phase is crucial for achieving the desired gear profile that allows for efficient meshing with the worm shaft, thus optimizing performance and reducing friction.

- Heat Treatment: Heat treatment is a vital step in enhancing the mechanical properties of the Magnetic Worm Gear. This process involves heating the gear to a specific temperature and then cooling it rapidly, which increases hardness and strength. The heat treatment process helps in alleviating stresses and improving the wear resistance of the gear, ensuring that it can handle demanding applications. Proper heat treatment extends the lifespan of Magnetic Worm Gear in various industrial settings.

- Surface Finishing: The surface finishing stage of the Magnetic Worm Gear manufacturing process enhances not only the aesthetic appeal but also the functional performance. Techniques such as grinding and polishing are employed to achieve a smooth surface, reducing friction between the gear and its mating components. A well-finished surface minimizes wear and tear, contributing to the longevity and efficiency of the Magnetic Worm Gear in machinery and equipment.

- Quality Inspection: The final stage in the manufacturing process of Magnetic Worm Gear involves rigorous quality inspection. Each gear is evaluated for dimensional accuracy, surface finish, and overall performance. Advanced testing methods, including non-destructive testing, are often utilized to ensure that the gears meet industry standards. This quality assurance step is essential to guarantee that the Magnetic Worm Gear will perform reliably in its intended application.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands. Our company specializes in providing high-quality magnetic worm gears that meet the diverse needs of our clients.

- Top-notch Quality: Our products are manufactured with precision, ensuring durability and reliability in various applications.

- Exceptional Service: We pride ourselves on our customer service, offering expert advice and support throughout the purchasing process.

- Industry Strength: With years of experience and a strong presence in the market, we have built a reputation for excellence and innovation.

Ek Bilgiler

| Edited | Zqq |

|---|

Bloglar Güncellendi

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...