In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

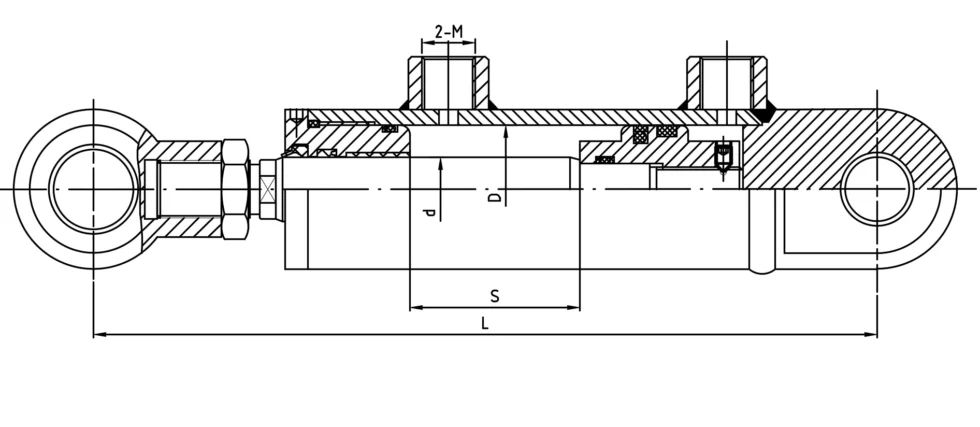

Locking Cylinder for Sanitation Machinery Technical Specification

|

|

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Ağırlık |

| Locking cylinder | 107504-00 | Φ40 | Φ20 | 53 | 245 | 25MPa | 2-G3/8 | 2.6kg |

|

|

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Ağırlık |

| Locking cylinder | 103631-00 | Φ63 | Φ40 | 160 | 385 | 30MPa | 2-G3/8 | 15kg |

Structural Composition of Locking Cylinders

The locking hydraulic cylinder is mainly composed of cylinder block, piston, piston rod, seal, connecting parts and locking mechanism. Among them, the cylinder body is the main part of the cylinder, which is used to contain the hydraulic oil; The piston and piston rod form a sealed chamber through the seal and the cylinder body, and when the hydraulic oil enters the chamber, it pushes the piston and piston rod to produce movement; Connecting parts are used to connect the cylinder with other parts of the sanitation vehicle; The locking mechanism is used to lock the position of the piston rod when needed to prevent it from moving.

Locking Cylinder Working Principle

The working principle of the locking hydraulic cylinder for sanitation vehicles is based on the principle of hydraulic transmission. When the hydraulic system supplies oil to the cylinder, the hydraulic oil enters the chamber of the cylinder through the tubing, and pushes the piston and piston rod to produce linear motion. When it is necessary to lock, the locking mechanism generates a locking force through air pressure or hydraulic pressure to fix the piston rod in the desired position. When unlocked, the locking force is lifted by the corresponding control signal, so that the piston rod can move freely.

Technical characteristics of Locking Cylinders

Large locking force: the locking hydraulic cylinder of the sanitation vehicle usually adopts a high-pressure hydraulic system, which can produce a large locking force to ensure the stability and safety of the sanitation vehicle in various working conditions.

Compact structure: In order to adapt to the limited space of the sanitation vehicle, the locking hydraulic cylinder usually adopts a compact structural design to ensure efficient locking function in the limited space.

Strong durability: the working environment of sanitation vehicles is harsh, and the locking hydraulic cylinder needs to bear a large load and impact. Therefore, the cylinder is usually made of high-quality materials and advanced manufacturing processes to ensure its high durability and reliability.

Easy to operate: the locking hydraulic cylinder for sanitation vehicles is usually combined with the electrical control system to achieve automatic control. The operator only needs to complete the locking and unlocking action through a simple button operation, which greatly improves the work efficiency.

Locking Cylinder Application Examples

In sanitation vehicles, locking hydraulic cylinders are widely used in various mechanisms that need to be locked and positioned. For example, in a compression garbage truck, the locking hydraulic cylinder is used to lock the turnover mechanism of the loader to ensure that the loader can be stably held in the desired position when the garbage is being filled; In the sweeper, the locking hydraulic cylinder is used to lock the cleaning brush and other components to ensure the stability and efficiency of the cleaning operation.

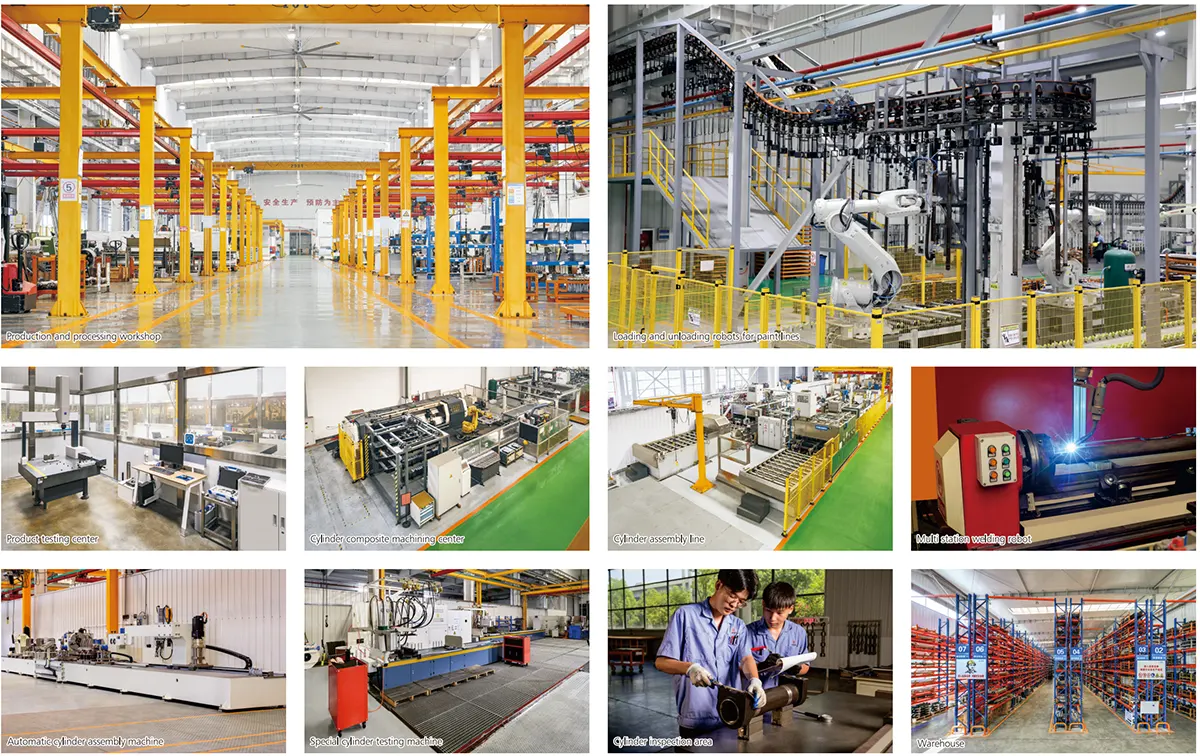

Hydraulic Cylinders for Sanitary Vehicles Manufacturer

Techniek BV proudly serves as the Netherlands sales agent for Ever-power Group, a renowned leader in hydraulic solutions. Our extensive expertise in manufacturing Locking Cylinders for Sanitation Machinery ensures that we provide top-quality products tailored to meet the demands of the sanitary vehicle industry. With a commitment to excellence, our team works diligently to deliver reliable and efficient hydraulic cylinders that enhance the performance of sanitation equipment, thereby supporting our clients in achieving their operational goals.

In addition to our standard hydraulic cylinders, we specialize in non-standard customization. We can manufacture hydraulic cylinders with a bore diameter of D360MM and a stroke length of L6000MM based on specific customer requirements. We invite all our customers to collaborate with us by providing drawings and samples for customized solutions that meet their unique needs.

Ek Bilgiler

| Edited by | Sylvia |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...