In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications

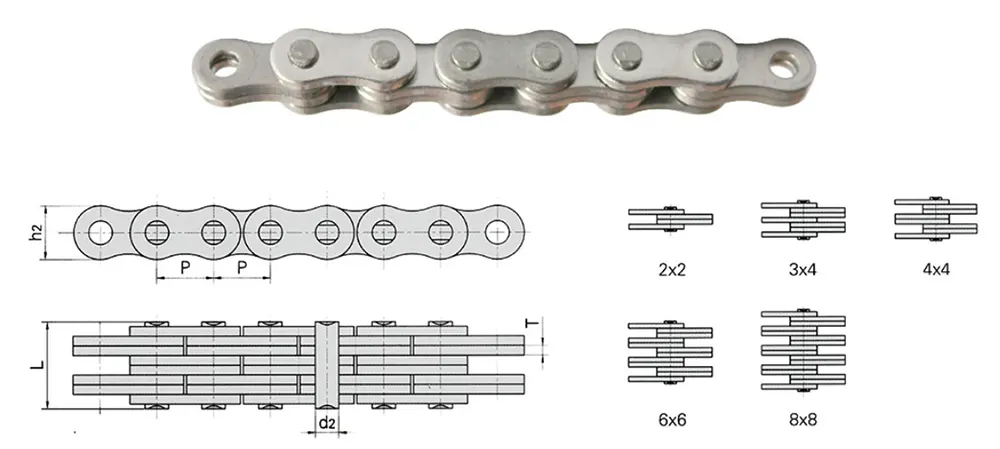

The LH2044SS/BL1044SS Stainless Steel Leaf Chain is a high-quality chain designed for various applications. It offers the following specifications:

- Material: Stainless Steel

- Type: Leaf Chain

- Model Number: LH2044SS/BL1044SS

- Finish: Stainless Steel

- Size: Varies (please refer to the product manual for specific dimensions)

- Weight: Depends on size

- Load Capacity: Varies (please refer to the product manual for specific load capacity)

- Corrosion Resistance: Excellent

- Operating Temperature: -40¡ãC to 200¡ãC

- Usage: Ideal for applications requiring high strength and corrosion resistance, such as industrial machinery, conveyor systems, and lifting equipment.

| Chain No. | Pitch | Lacing | Plate thickness | Plate depth | Pin diameter | Pin length | Breaking load | Average tensile strength | |

| ISO GB |

ANSI | P(mm) | T(mm) | h2(mm) | d2(mm) | L(mm) | Q min(KN) |

Q0(KN) | |

| LH2022SS | BL1022SS | 31.75 | 2x2 | 4.9 | 30.1 | 11.1 | 25.1 | 80.962 | 103.11 |

| LH2023SS | BL1023SS | 31.75 | 2x3 | 4.9 | 30.1 | 11.1 | 30 | 80.962 | 103.11 |

| LH2034SS | BL1034SS | 31.75 | 3x4 | 4.9 | 30.1 | 11.1 | 40.2 | 127.911 | 162.33 |

| LH2044SS | BL1044SS | 31.75 | 4x4 | 4.9 | 30.1 | 11.1 | 45.2 | 161.91 | 204.33 |

| LH2046SS | BL1046SS | 31.75 | 4x6 | 4.9 | 30.1 | 11.1 | 55 | 161.91 | 204.33 |

| LH2066SS | BL1066SS | 31.75 | 6x6 | 4.9 | 30.1 | 11.1 | 65 | 242.865 | 301 |

| LH2088SS | BL1088SS | 31.75 | 8x8 | 4.9 | 30.1 | 11.1 | 84.8 | 323.82 | 388.43 |

| LH2422SS | BL1222SS | 38.1 | 2x2 | 5.6 | 36 | 12.7 | 28 | 105.868 | 134.61 |

| LH2423SS | BL1223SS | 38.1 | 2x3 | 5.6 | 36 | 12.7 | 33.7 | 105.868 | 134.61 |

| LH2434SS | BL1234SS | 38.1 | 3x4 | 5.6 | 36 | 12.7 | 44.8 | 171.248 | 216.02 |

| LH2444SS | BL1244SS | 38.1 | 4x4 | 5.6 | 36 | 12.7 | 50.6 | 211.729 | 267.19 |

| LH2446SS | BL1246SS | 38.1 | 4x6 | 5.6 | 36 | 12.7 | 61.7 | 211.729 | 267.19 |

| LH2466SS | BL1266SS | 38.1 | 6x6 | 5.6 | 36 | 12.7 | 73.4 | 317.59 | 380.03 |

| LH2488SS | BL1288SS | 38.1 | 8x8 | 5.6 | 36 | 12.7 | 96 | 423.458 | 507.71 |

| LH2822SS | BL1422SS | 44.45 | 2x2 | 6.4 | 42 | 14.27 | 31.7 | 133.889 | 158.34 |

| LH2823SS | BL1423SS | 44.45 | 2x3 | 6.4 | 42 | 14.27 | 38.2 | 133.889 | 158.34 |

| LH2834SS | BL1434SS | 44.45 | 3x4 | 6.4 | 42 | 14.27 | 51.2 | 221.067 | 260.47 |

| LH2844SS | BL1444SS | 44.45 | 4x4 | 6.4 | 42 | 14.27 | 57.5 | 267.771 | 315.49 |

| LH2846SS | BL1446SS | 44.45 | 4x6 | 6.4 | 42 | 14.27 | 70.5 | 267.771 | 315.49 |

| LH2866SS | BL1466SS | 44.45 | 6x6 | 6.4 | 42 | 14.27 | 83.3 | 404.768 | 478.03 |

| LH2888SS | BL1488SS | 44.45 | 8x8 | 6.4 | 42 | 14.27 | 109.5 | 535.542 | 632.31 |

| LH3222SS | BL1622SS | 50.8 | 2x2 | 7.5 | 48 | 17.46 | 36.8 | 202.384 | 239.19 |

| LH3223SS | BL1623SS | 50.8 | 2x3 | 7.5 | 48 | 17.46 | 44.4 | 202.384 | 239.19 |

| LH3234SS | BL1634SS | 50.8 | 3x4 | 7.5 | 48 | 17.46 | 59.4 | 308.252 | 364 |

| LH3244SS | BL1644SS | 50.8 | 4x4 | 7.5 | 48 | 17.46 | 67 | 404.768 | 476.49 |

| LH3246SS | BL1646SS | 50.8 | 4x6 | 7.5 | 48 | 17.46 | 82.4 | 404.768 | 476.49 |

| LH3266SS | BL1666SS | 50.8 | 6x6 | 7.5 | 48 | 17.46 | 97.6 | 600.152 | 700 |

| LH3288SS | BL1688SS | 50.8 | 8x8 | 7.5 | 48 | 17.46 | 128.1 | 809.536 | 954.8 |

Title 1: Introduction to LH2044SS/BL1044SS Stainless Steel Leaf Chain

The LH2044SS/BL1044SS Stainless Steel Leaf Chain is a high-quality and durable chain designed for various industrial applications. This chain is manufactured using stainless steel, making it resistant to corrosion and suitable for use in harsh environments. With its exceptional strength and reliability, the LH2044SS/BL1044SS Stainless Steel Leaf Chain is an ideal choice for demanding applications.

Title 2: Features of LH2044SS/BL1044SS Stainless Steel Leaf Chain

High Tensile Strength

The LH2044SS/BL1044SS Stainless Steel Leaf Chain is engineered with a high tensile strength, ensuring it can withstand heavy loads and provide reliable performance in demanding conditions.

Corrosion Resistance

Thanks to its stainless steel construction, this leaf chain offers excellent corrosion resistance. It is designed to withstand exposure to moisture, chemicals, and other corrosive elements, making it suitable for applications in challenging environments.

Smooth Operation

The LH2044SS/BL1044SS Stainless Steel Leaf Chain is designed for smooth and efficient operation. It features precision-machined components that minimize friction and ensure smooth movement, reducing wear and extending chain life.

Easy Installation

This leaf chain is designed for easy installation, saving time and effort during assembly. Its well-designed links and connectors allow for quick and hassle-free setup, ensuring minimal downtime and increased productivity.

Wide Range of Applications

The LH2044SS/BL1044SS Stainless Steel Leaf Chain can be used in various industries and applications. It is commonly employed in conveyor systems, material handling equipment, agricultural machinery, and other industrial settings that require reliable and robust chain solutions.

Title 3: Specifications of LH2044SS/BL1044SS Stainless Steel Leaf Chain

- Material: Stainless steel

- Chain Type: Leaf Chain

- Size: LH2044SS (insert specific dimensions) / BL1044SS (insert specific dimensions)

- Tensile Strength: (insert specific value) lbs

- Corrosion Resistance: Excellent

- Operating Temperature: -40¡ãC to +200¡ãC

- Weight: (insert specific weight) lbs/ft

- Breaking Load: (insert specific value) lbs

- Certification: ISO 9001:2015

Title 4: Maintenance and Care for LH2044SS/BL1044SS Stainless Steel Leaf Chain

Proper maintenance and care are essential to ensure optimal performance and longevity of the LH2044SS/BL1044SS Stainless Steel Leaf Chain. Here are some guidelines to follow:

Regular Lubrication

Apply a suitable lubricant to the chain regularly to minimize friction and prevent excessive wear. This will help maintain smooth operation and extend the chain's lifespan.

Inspection and Cleaning

Periodically inspect the chain for any signs of damage, such as bent or broken links. Clean the chain using a mild detergent and water to remove dirt, debris, and contaminants that can affect its performance.

Tension Adjustment

Ensure the chain is properly tensioned to prevent slack or excessive tightness. Improper tension can lead to premature wear and reduced performance.

Environmental Considerations

Avoid exposing the chain to extreme temperatures, chemicals, or other environmental factors that can compromise its integrity. Proper storage and handling are crucial to maintaining the chain's quality.

Title 5: Conclusion

The LH2044SS/BL1044SS Stainless Steel Leaf Chain is a reliable and durable chain that offers exceptional strength, corrosion resistance, and smooth operation. With its easy installation, wide range of applications, and low maintenance requirements, it is the ideal choice for various industrial settings. Trust the LH2044SS/BL1044SS Stainless Steel Leaf Chain for your chain needs and experience enhanced performance and reliability.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV, as the Netherlands sales agent of Ever-power Group, is proud to offer high-quality stainless steel roller chains. Our commitment to excellence is exemplified by our LH2044SS/BL1044SS Stainless Steel Leaf Chain, which stands out for its unique selling points.

When it comes to our stainless steel roller chains, we prioritize product quality, durability, and reliability. Our chains are manufactured using premium stainless steel materials, ensuring resistance to corrosion, wear, and high temperatures. This guarantees a longer lifespan and reduces maintenance costs.

Another key advantage of choosing our stainless steel roller chains is the exceptional level of service we provide. Our knowledgeable and professional team is dedicated to assisting customers, offering expertise, guidance, and personalized solutions to meet specific requirements.

Furthermore, RP Techniek BV and Ever-power Group boast a robust production capability. We have state-of-the-art manufacturing facilities equipped with advanced machinery and technologies, enabling us to consistently deliver superior stainless steel roller chains.

In addition to the LH2044SS/BL1044SS Stainless Steel Leaf Chain, we offer a wide range of other stainless steel roller chains to cater to diverse needs. Our extensive selection ensures that customers can find the perfect chain for any application, whether it be in the automotive, food processing, or industrial sectors.

Sprockets for Sale

When it comes to finding the perfect match for your LH2044SS/BL1044SS Stainless Steel Leaf Chain, our company offers a wide range of different types of sprockets to meet your needs.

Our sprockets are designed with precision and durability in mind. They are made from high-quality materials to ensure long-lasting performance. With our extensive selection, you can find the right sprocket that perfectly complements your chain, providing smooth and efficient operation.

Whether you require a standard sprocket, a custom design, or a specialized sprocket for specific applications, we have you covered. Our inventory includes various sizes, tooth configurations, and bore options, allowing you to choose the ideal sprocket for your machinery.

At our company, we understand the importance of reliable and efficient equipment in your business operations. That's why we focus on delivering top-notch sprockets that meet the highest standards of quality and performance.

Ek Bilgiler

| Editor | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...