In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Gripper Chains with Simple Frame Clamp Specifications

| HZPT Code | DIN/ISO | Material | Pitch | Inside Width | Roller Dia | Clamp Moving | Clamp Force | Tensile Strength | |||

| Base Chain | Clamp | Spring | P mm |

b1 Max mm |

d1 Max mm |

Vertical x mm |

Horizontal y mm |

Q-C N |

Q Min. kN |

||

| 08B1GC-A | 08B-1 | SS | SS | SS | 12.7 | 7.75 | 8.51 | 3 | һ | 85 | 15 |

| 08B-1 | NP | SS | SS | 12.7 | 7.75 | 8.51 | 3 | һ | 85 | 18 | |

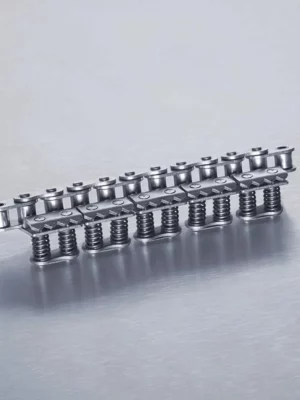

Overview of Gripper Chains with Type A Simple Frame Clamp

The Gripper Chains with Type A Simple Frame Clamp is a highly efficient and reliable solution for various Form, Fill, and Vacuum Seal wrapping applications. Designed with a vertically opening Simple Frame Clamp (Type A), this gripper chain offers precise clamping force through its innovative cam shape mechanism.

Features:

- Base Chains available in Nickel Plated and Stainless Steel options, ensuring superior corrosion resistance.

- Stainless springs made from high-quality Japan-imported material, guaranteeing consistent clamping force.

- Pin & Bush components crafted from AISI 630HT, providing exceptional wear-resistance for stainless steel base chains.

- Supplied in Pre-stretched and matched strands, facilitating trouble-free machine set-up.

- Lube-free Nickel Plated chain version available upon request.

Applications:

- Food Industry: Ideal for packaging ham, sausage, cheese, bread, fish, and more.

- Electronics Industry: Suitable for packaging wires and other electronic components.

- Medical Industry: Reliable packaging solution for injection syringes, pharmaceutical products, and more.

With its exceptional functionality and dependable performance, the Gripper Chains with Type A Simple Frame Clamp is the perfect choice for businesses in need of efficient and precise wrapping solutions.

Gripper Chains with Type A Simple Frame Clamp Features

The Gripper Chains with Type A Simple Frame Clamp offer a range of impressive features that make them an ideal choice for various applications. These chains are designed to open vertically through slight lateral movement, allowing them to follow the cam shape effortlessly.

1. Excellent Corrosion Resistance: Available in Nickel Plated and Stainless Steel options, these chains are highly resistant to corrosion, ensuring long-lasting performance.

2. Reliable Clamping Force: The stainless springs used in these chains are made from high-quality, Japan-imported material, ensuring a consistent and reliable clamping force.

3. Outstanding Wear-Resistance: For chains with a stainless steel base, the Pin & Bush components are made of AISI 630HT material, providing exceptional wear-resistance.

4. Trouble-Free Machine Set-Up: Supplied in pre-stretched and matched strands, these chains guarantee a hassle-free machine set-up, saving valuable time and effort.

5. Lube-Free Option: Additionally, a lube-free Nickel Plated chain version is available upon request, offering convenience and ease of use.

To better visualize the Gripper Chains with Type A Simple Frame Clamp, please refer to the following image:

These features collectively make our Gripper Chains with Type A Simple Frame Clamp an exceptional choice for applications in various industries, including food, electronics, and medical, where reliable clamping and efficient performance are crucial.

Applications of Gripper Chains with Type A Simple Frame Clamp

- Form, Fill and Vacuum Seal wrapping applications in various industries

- Packaging for Ham, sausage, cheese, bread, fish and other food products in the food industry

- Packaging for wires and other electronic components in the electronics industry

- Packaging for injection syringe, pharmaceutical and other medical products in the medical industry

These chains are equipped with a Type A Simple Frame Clamp that opens vertically with a slight lateral movement to follow the cam shape. The Gripper Chains with Base Chains are available in both Nickel Plated and Stainless Steel, offering excellent corrosion resistance. Additionally, the Stainless springs are made of Japan-imported material which ensures the clamping force remains consistent. The Pin & Bush of the Stainless steel base chain is made of AISI 630HT, which provides outstanding wear-resistance. The chains are supplied in pre-stretched and matched strands, which guarantee trouble-free machine set-up. For those who require a lube-free version, the Nickel Plated chain is also available upon request.

How Does Grip Chains Work?

In the case of the Gripper Chains with Type A Simple Frame Clamp, the chain operates on a simple yet effective principle. The grip chains are designed with specially designed links that interlock with each other. This interlocking mechanism allows the chain to form a continuous loop when properly assembled.

The main purpose of this grip chain is to securely hold objects in place during various industrial applications. The interlocked links of the chain create a strong and reliable grip on the object being clamped. This ensures that the object remains firmly in position, even when subjected to external forces or vibrations.

Maintenance of Gripper Chains

In this section, we will discuss the maintenance of the gripper chains with Type A Simple Frame Clamp. The following points outline the key aspects of maintaining these chains:

1. Regular Lubrication: It is essential to lubricate the gripper chains regularly to ensure smooth operation. Apply a suitable lubricant to all moving parts of the chain, including the pins, rollers, and bushings.

2. Chain Tension: Check the tension of the gripper chains periodically to ensure optimal performance. Adjust the tension according to the manufacturer's guidelines. Improper tension can lead to excessive wear and reduce the lifespan of the chains.

3. Inspection of Wear: Regularly inspect the gripper chains for any signs of wear or damage. Look for elongation, cracks, or excessive stretching of the chain links. Replace any worn-out or damaged chains immediately to prevent further issues.

4. Cleaning: Maintain cleanliness by regularly cleaning the gripper chains. Remove any dirt, debris, or contaminants that may accumulate on the chain links. Use a suitable cleaning agent and ensure thorough drying before reassembling.

5. Proper Storage: When not in use, store the gripper chains in a dry and clean environment. Protect them from extreme temperatures, moisture, and corrosive substances that can deteriorate the chain's condition.

Remember, regular maintenance and care of the gripper chains will extend their lifespan and ensure optimal performance.

[](https://netherlandsdrive.com/wp-content/uploads/2024/11/gripper-chain-4.jpg)

Sprockets for Gripper Chains

In Gripper Chains with Type A Simple Frame Clamp, the chains and sprockets work together in perfect harmony to ensure efficient operation of the machinery. The chains are responsible for carrying the load, while the sprockets engage with the chain's teeth to create movement. The relationship between the two is vital, and they rely on each other to function properly.

To ensure optimal performance, Gripper Chains with Type A Simple Frame Clamp require high-quality sprockets that are specifically designed to match the chain's pitch, bore, and tooth count. At our company, we offer a range of sprockets that are compatible with Gripper Chains with Type A Simple Frame Clamp and are designed to provide maximum durability and wear resistance.

We understand the importance of having the right sprockets for your gripper chains, which is why we offer a wide range of sprockets that are designed to match the specifications of your chain. We also offer consultation services to help you choose the right sprockets for your specific application.

Please see the image below for an example of the sprockets we offer for Gripper Chains with Type A Simple Frame Clamp:

Hakkımızda

RP Techniek BV is the Netherlands sales agent of Ever-power Group. We are proud to represent and promote our Gripper Chains with Type A Simple Frame Clamp products.

Our Gripper Chains are designed to provide reliable and efficient solutions for various industries. With their innovative design and high-quality materials, they ensure optimal performance and durability.

We take pride in our strong manufacturing capabilities and commitment to producing top-notch products. Our team of skilled professionals utilizes advanced technology to ensure the highest standards of product quality.

Not only do we offer exceptional products, but we also strive to provide excellent customer service. Our dedicated team is always ready to assist you with any inquiries and provide prompt support.

We strongly encourage you to explore our Gripper Chains with Type A Simple Frame Clamp products and contact us for purchasing. Don't miss out on the opportunity to enhance your operations with our reliable and efficient solutions.

Please find below an image showcasing our products:

Ek Bilgiler

| Editor | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...