In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

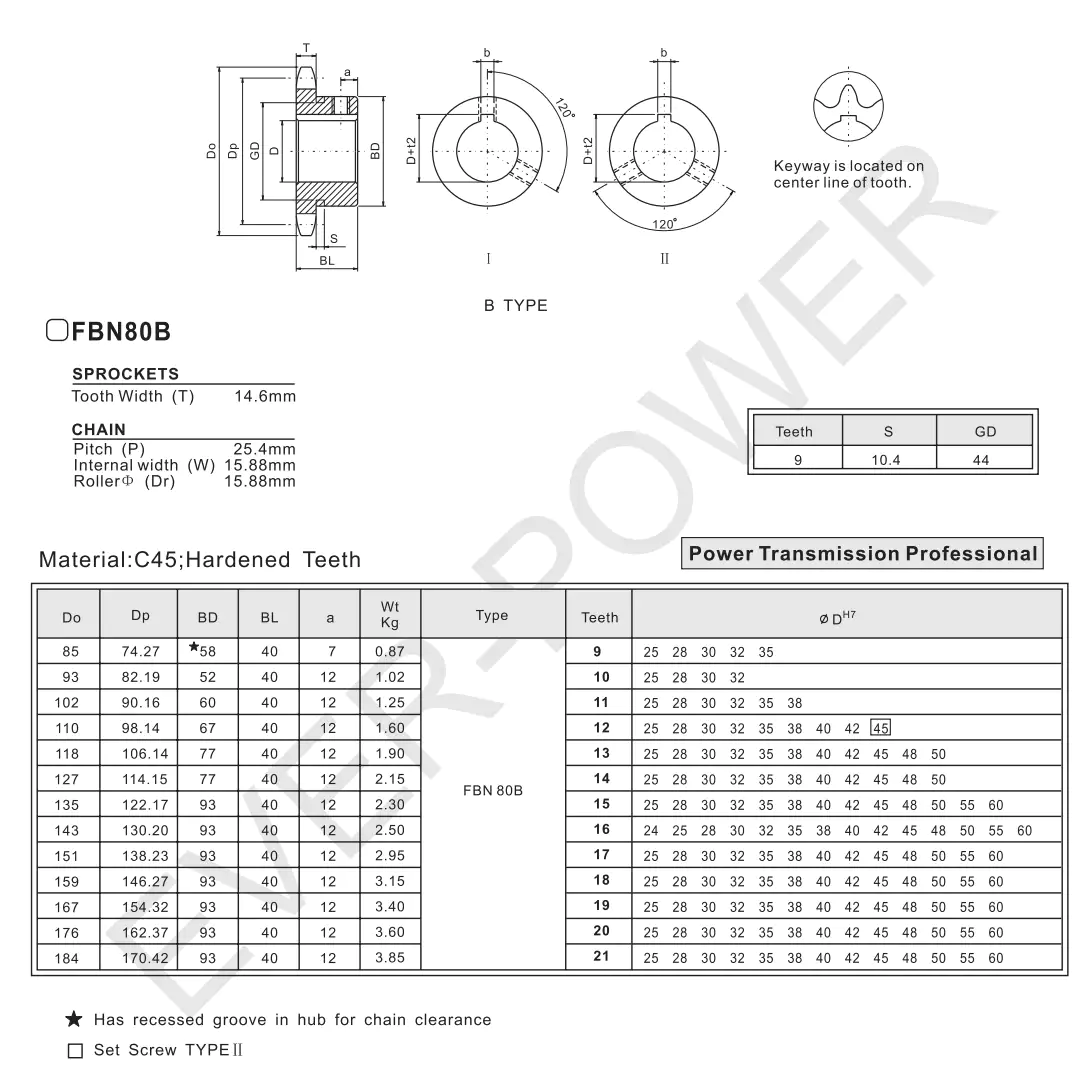

FBN80B Finished Bore Sprocket

The FBN80B Finished Bore Sprocket is engineered for precision and durability, making it ideal for various industrial applications. Constructed from high-quality materials, this sprocket ensures optimal performance and longevity. Its finished bore design offers ease of installation, providing a reliable solution for power transmission needs in machinery and equipment.

Specifications of FBN80B Finished Bore Sprocket

Introduction to Finished Bore Sprocket

A finished bore sprocket is a crucial component often utilized in machinery, consisting of a toothed wheel that engages with chains, belts, or other perforated materials to effectively transmit rotary motion between two rotating shafts. The FBN80B Finished Bore Sprocket is meticulously designed with a completed bore diameter, allowing for easy and efficient installation onto a shaft without the need for any additional machining processes.

Material and Manufacturing Process

Constructed from high carbon steel, alloy steel, or stainless steel, the FBN80B Finished Bore Sprocket undergoes a thorough selection process to ensure the best quality. The manufacturing process includes cutting, stamping, forging, machining, heat treatment, and surface hardening. To enhance durability, the surface is treated with anti-rust measures, and comprehensive quality inspections are conducted throughout production to deliver high-quality sprockets to our customers.

Applications of Sprockets

Sprockets are extensively utilized across various industries, including sectors like heavy machinery, food processing, packaging, chemical manufacturing, pharmaceuticals, assembly lines, logistics, and warehousing. Their primary role is to effectively transmit power and facilitate motion between rotating shafts or conveyor belts, making them indispensable in industrial applications.

Maintenance and Troubleshooting of Sprockets

To extend the lifespan of a sprocket, regular maintenance and care are imperative. Daily tasks such as thorough inspections, cleaning, lubrication, adjustment, and calibration are vital for maintaining sprocket efficiency. Common issues that may arise include tooth skipping, breakage, wear, noise, and chain detachment. To resolve these problems, suitable solutions include adjusting chain tension, replacing the sprocket, lubricating the chain, or realigning the sprocket properly to ensure optimal performance.

Other Types of Sprockets and Chains

In addition to the FBN80B Finished Bore Sprockets, our company provides a variety of other sprocket types, including taper lock sprockets, QD sprockets, idler sprockets, and more. Furthermore, we offer an extensive selection of different models and types of chains to meet diverse customer needs.

Sprockets Supplier in Netherlands

RP Techniek BV is a prominent sales agent for Ever-power Group in the Netherlands, dedicated to delivering high-quality sprockets that cater to a wide range of industrial requirements. Among our distinguished products is the FBN80B Finished Bore Sprocket, engineered for exceptional durability and efficiency specifically in power transmission applications. Our sprockets are manufactured from top-grade materials, ensuring reliable performance, even in challenging working environments.

Beyond standard sprockets, RP Techniek BV specializes in offering customized solutions tailored to meet customer specifications. We encourage clients to present their unique designs and samples for bespoke manufacturing that aligns with their specific requirements. Our unwavering commitment to quality and customer satisfaction solidifies our position as the preferred choice for sprocket solutions in the Netherlands.

Ek Bilgiler

| Edited | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...