In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

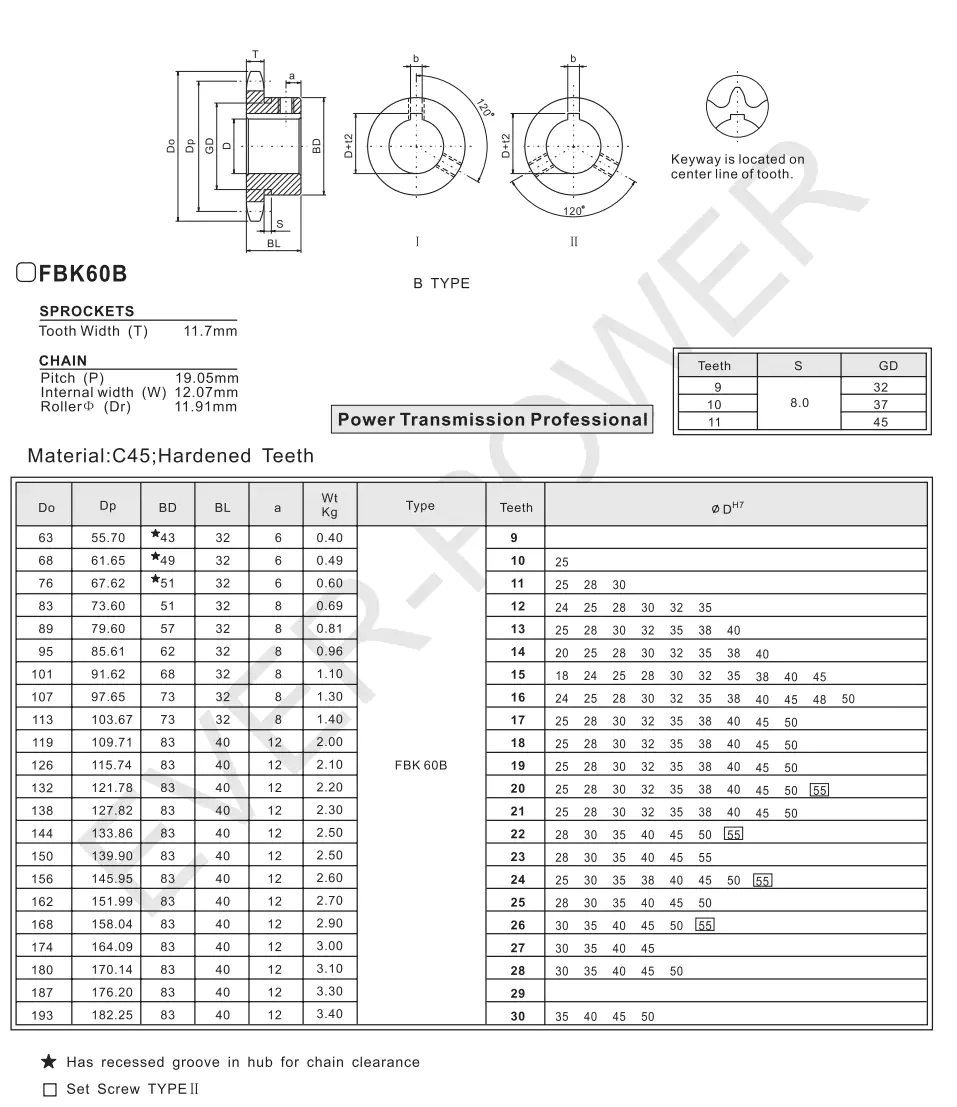

FBK60B Finished Bore Sprocket

The FBK60B Finished Bore Sprocket is designed for high-performance applications, featuring precision-engineered teeth for optimal engagement with chains. Made from durable materials, it ensures longevity and reliability in demanding environments. Ideal for various industrial machinery, this sprocket offers easy installation and maintenance, making it a perfect choice for enhancing operational efficiency.

Specifications of FBK60B Finished Bore Sprocket

A finished bore sprocket, such as the FBK60B, is specifically engineered with a pre-bored hole that perfectly accommodates a designated shaft size. This design makes it ideal for a multitude of industrial applications where reliable power transmission is essential. The FBK60B not only meets but exceeds the requirements set forth by the Asian Standard, ensuring its performance and compatibility across various machinery.

Materials and Manufacturing Process

- Materials: The construction of finished bore sprockets typically involves high carbon steel, alloy steel, or stainless steel. Each material is selected based on the specific application needs, ensuring that the sprocket performs optimally under various conditions.

- Manufacturing Process: The production of these sprockets encompasses a series of steps, including the selection of the right material, cutting, stamping, forging, and machining processes such as turning, milling, and drilling. Additionally, heat treatment processes like quenching and tempering are employed, followed by surface hardening, rust prevention measures, and a thorough quality inspection to ensure reliability and performance.

Maintenance and Care of Sprockets

Proper maintenance and care are vital for ensuring the longevity and optimal performance of sprockets. Regular attention to these components can prevent costly breakdowns and extend their service life. Here are some essential maintenance tips:

- Conduct daily inspections to identify any signs of damage or wear that may affect performance.

- Engage in regular cleaning to remove dirt, debris, and contaminants that could impede function.

- Apply lubrication systematically to reduce friction and prevent corrosion from taking hold.

- Make necessary adjustments and calibrations to guarantee that alignment and tension are both accurate and effective.

Common issues that may arise with sprockets include tooth skipping, breakage, wear, excessive noise, and chain derailing. Here are some effective solutions:

- For tooth skipping, check for misalignment and make adjustments where needed. Any worn components should be replaced promptly.

- In the event of breakage, inspect the sprocket for visible cracks or signs of fatigue and replace it if necessary.

- Monitor wear regularly, and replace the sprocket if significant wear is detected.

- If excessive noise is noted, ensure proper lubrication and check for any loose chains or worn sprockets that may be causing the issue.

- To address chain derailing, verify correct tension and alignment, making adjustments as required and replacing any damaged parts.

Other Types of Sprockets and Chains

Besides finished bore sprockets, a variety of other sprocket types are available, including taper lock sprockets, QD sprockets, and idler sprockets, alongside various models of chains to fulfill different needs.

Sprockets Supplier in Netherlands

RP Techniek BV is a prominent sales agent for Ever-power Group, a leading manufacturer in the sprockets industry. We take pride in providing high-quality products, such as the FBK60B Finished Bore Sprocket, which is designed for durability and efficiency across a range of applications. Our sprockets are manufactured using premium materials, ensuring long-lasting performance and reliability.

In addition to our standard offerings, we specialize in custom solutions tailored to the unique requirements of our customers. Our dedicated team is prepared to assist you with bespoke designs based on your specifications or samples. We encourage all customers to reach out for tailored sprocket solutions that meet their specific needs.

Ek Bilgiler

| Edited | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...