The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

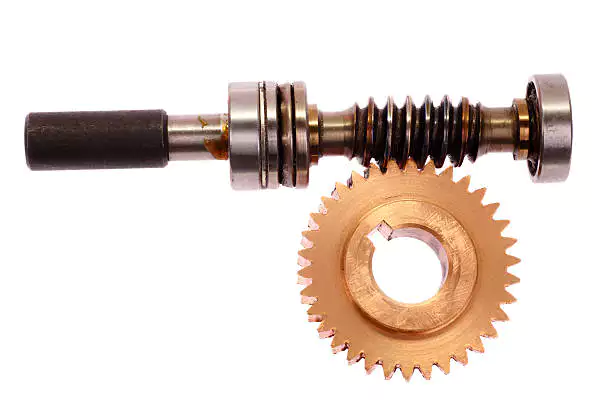

Cylindrical Worm Wheel

The Cylindrical Worm Wheel is a crucial component in power transmission systems, designed to work seamlessly with a Cylindrical Worm Gear. Made from high-quality materials, it ensures durability and efficiency. The Worm Shaft and Worm Screw interact with the Worm Wheel to provide smooth rotational movement, making it essential for various mechanical applications.

Details of Cylindrical Worm Wheel

| Parameter | Value |

|---|---|

| Material | Alloy Steel |

| Çap | 50 mm |

| Gear Ratio | 5:1 |

| Pitch | 2 mm |

| Load Capacity | 500 N |

| Efficiency | 90% |

Features of Cylindrical Worm Wheel

- High Efficiency: The Cylindrical Worm Wheel, paired with a Cylindrical Worm Gear, offers superior torque transmission, ensuring efficient power transfer in various applications.

- Compact Design: Known for its space-saving design, the Worm Gear system allows for a smaller footprint, making it ideal for tight installations where a Worm Shaft is required.

- Low Noise Operation: The meshing of the Worm Screw with the Worm Wheel ensures minimal noise during operation, which is crucial for applications requiring quiet performance.

- Durability: Made from high-quality materials, the Worm Gear and Worm Wheel combination provides excellent wear resistance, extending the lifespan of the components.

Working Principle of the Cylindrical Worm Wheel

The Cylindrical Worm Wheel operates seamlessly with its counterpart, the Cylindrical Worm Gear. This mechanism utilizes a Worm Shaft that engages with the Worm Wheel, allowing for smooth rotational motion. The Worm Screw design ensures efficient torque transmission while minimizing backlash. The combination of the Worm Gear and Cylindrical Worm Wheel provides a high reduction ratio, making it ideal for various applications where space constraints and performance are critical. This innovative design is trusted in many industries for its reliability and efficiency.

Manufacturing Process of Cylindrical Worm Wheel

- Design Phase: The manufacturing of a Cylindrical Worm Wheel starts with a comprehensive design phase. Engineers utilize CAD software to create precise models of the Worm Gear and Worm Shaft, ensuring that the dimensions meet specific operational requirements. This phase is critical as it determines the efficiency and compatibility of the Worm Wheel within a gear system. Attention is given to the tooth profile, material selection, and overall geometry to enhance performance and durability. The design must accommodate not only the Worm Screw but also the interaction with other components in the mechanism.

- Material Selection: Choosing the right material is paramount in producing a high-quality Cylindrical Worm Wheel. Typically made from steel, bronze, or plastic, the material impacts the wheel's strength, wear resistance, and thermal properties. For instance, a Worm Gear made from bronze may provide better wear characteristics than a steel alternative, while plastic gears can be lightweight and corrosion-resistant. This selection process ensures that the Worm Shaft and Worm Wheel can withstand the operational stresses and maintain high efficiency over time.

- Machining Process: The machining process is vital in shaping the Worm Wheel accurately. Techniques such as CNC milling and grinding are employed to achieve the necessary precision. The production of the Worm Gear involves cutting the helical teeth profile, which is crucial for smooth operation. Each tooth must be crafted with exact tolerances to ensure effective meshing with the Worm Screw. This phase also includes drilling and boring operations for the Worm Shaft, which must align perfectly with the Worm Wheel to minimize friction and wear.

- Heat Treatment: To enhance the mechanical properties of the Cylindrical Worm Wheel, heat treatment processes such as quenching and tempering are applied. This step increases hardness and durability, which is essential for the Worm Gear that will engage with the Worm Shaft under load. The heat treatment not only ensures longevity but also reduces the likelihood of deformation during operation. Proper heat treatment makes the Worm Wheel more resilient against wear and extends its service life significantly.

- Quality Control: After manufacturing, each Cylindrical Worm Wheel undergoes rigorous quality control testing. This includes dimensional checks, hardness testing, and performance evaluations to ensure that the Worm Gear meets industry standards. Any defects or deviations can lead to inefficiencies or failures in the gear system. Inspections are crucial to confirm that the Worm Wheel, along with the Worm Shaft, operates smoothly and reliably in its intended applications.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for the Ever-power Group in the Netherlands, and we are proud to be one of the top ten worm gear suppliers in the country. Our expertise in the field allows us to offer high-quality products, including cylindrical worm wheels that meet the highest industry standards.

- Our cylindrical worm wheels are designed for precision and durability, ensuring optimal performance in various applications.

- We pride ourselves on our exceptional quality and craftsmanship, produced using advanced manufacturing techniques.

- Our strong financial position and industry experience enable us to deliver robust solutions for all your worm gear needs.

- Customer satisfaction is our top priority, and we provide outstanding service and support throughout your purchasing journey.

Ek Bilgiler

| Edited | Zqq |

|---|

Bloglar Güncellendi

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...